Steve Cook

Flying Squad

I've been a big fan of the 18" gauge loco 'Jack' built by the Hunslet Engine Company for many years and have long harboured a wish to own a model of one. I got as far as purchasing some parts from Roundhouse a couple of years ago and started to research the build but as ever, my interests moved around and it got consigned to the back burner. A kick up the posterior arrived this year with the serialisation of Brian Wilsons build in Garden Rail magazine (noted here) but the more I looked, the more I wasn't happy with the compromises made.

Having mulled it over some more, I've decided to go back to scratch building my version, but using the Roundhouse cylinders and valve gear, along with the really useful parts made to support the Garden Rail build. I had planned to start with the frames but after further consideration, I figured I would be best building the known components first (smokebox, cylinders etc) and design the frames around those 'fixed' parts.

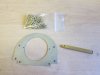

I've spent a bit of time sorting out my lathe recently and with a few tools as Christmas presents, the smokebox has been the first thing to be constructed. The basic kit parts are supplied by Model Engineers Laser for £22.50 and save a whole load of marking out, especially the smokebox curves.

From left too right we have the smokebox front, front inner wrapper support, rear inner wrapper support, smokebox rear and smokebox ring. The wrapper is below but will not be used as anything other than a test piece - its supplied drilled for 1/16 rivets and I will be using 3/64 rivets at a different spacing and on both edges to represent Jack as built.

The smokebox ring was covered with permanent marker and the centre line scribed around, before four marks were made at 90 degree intervals. The ring was clamped to the smokebox rear so the fixing holes could be drilled through both components.

Countersinks were added to both components ready for riveting.

Rivets were added through each hole and bashed into place with a ball pein hammer (rear ones fully formed, front ones waiting for the hammer bows).

The smokebox door keep was next. The fixing holes were drilled into the smokebox front and the position of these transferred to a length of 5mm square brass bar.

As before, both components are countersunk to give something for the rivets to form into

Lots more gentle blows with the hammer and a quick dress with a file saw the front completed.

The heads of the rivets were then hammered into the rear of the door keep, then filed flat.

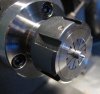

A set of spacers were turned up from 1/4" brass bar stock.

The smokebox was then loosely assembled to check alignment.

Its a bit nerve racking, swinging a large hammer when there isn't much room for error - fortunately I only caught the smokebox ring the once

It takes a while to gently start compressing the brass into the countersinks on the outside of the smokebox - its definitely a job not worth rushing.

It takes a while to gently start compressing the brass into the countersinks on the outside of the smokebox - its definitely a job not worth rushing.

A bit more bashing, quite a lot of filing using different grades of file, then a finish off with 600 grit wet and dry and its come out OK.

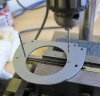

A new smokebox wrapper was cut out next from 1.45mm mild steel sheet.

The perspex bits can survive the odd smack with a hammer too - its all to easy to concentrate on not moving the base and forgetting to swap in the punch

The perspex bits can survive the odd smack with a hammer too - its all to easy to concentrate on not moving the base and forgetting to swap in the punch  patience is not my strong point

patience is not my strong point

The one thing I was trying to avoid and I did it straight off...

The one thing I was trying to avoid and I did it straight off...

, used it to form the wooden shapes for my aborted class 40 and Deltic in gauge 1 and frames for my 1:96 US warship hull. Some of it was ok, the theory was sound but as always it's the application, the armored chines were not straight enough and I gave up and got back into trains. It's still in the loft, still square and solid, thought it would of bowed by now, it could be cleaned up and made presentable, just a case of finding the time.

, used it to form the wooden shapes for my aborted class 40 and Deltic in gauge 1 and frames for my 1:96 US warship hull. Some of it was ok, the theory was sound but as always it's the application, the armored chines were not straight enough and I gave up and got back into trains. It's still in the loft, still square and solid, thought it would of bowed by now, it could be cleaned up and made presentable, just a case of finding the time.