Mike Trice

Western Thunderer

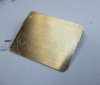

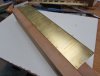

As mentioned earlier I am cross kitting Comet D186 Gresley Sides with MJT Floorpan. The MJT Floorpan looks like this:

When I developed the MJT range my concept was to assemble the sides, ends and floor as one unit with the roof being fitted separately. For this build I wanted to try building the sides, ends and roof as one component and have the floor removable.

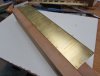

Taking the basic floor pan the centre line was scribed and a centre point pop marked:

The resulting pop-mark was opened out by drilling up to 2.5mm

The etched ends were snapped off and the tabs cleaned up:

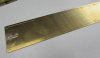

At this point I asked my previous question regarding the folding of the side lips to 90 degrees. I more or less followed the method outlined then starting by scribing the etched fold lines with a knife blade until the result could be seen from the other side:

A folding jig was made up from 2 lengths of scrap timber and screwed together. The outside lip was then clamped in the jig. Somewhere I have a set of Blacksmith bending bars which would need finding and getting the vice out etc and it was actually easier to knock the wooden version together:

The centre section was then bent against the work surface:

A full 90 degrees was not really possible and I would guess I only managed about 85 degrees in the jig:

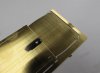

The last 5 degrees were tweaked using a steel ruler and engineer's square. New fixings to attach the ends to the floorpan were made up from K&S 1/4" angle cut to length then centre popped and drilled 2.5mm:

Using a cocktail stick to align the items a brass M2 nut was soldered to the angle bracket:

The angle bracket was now soldered to the end leaving a 12thou rebate at the bottom so it would sit against the floorpan:

With a little opening out of the holes in the floorpan (elongating with a rat tail needle file) the ends could now be bolted to the floorpan:

When I developed the MJT range my concept was to assemble the sides, ends and floor as one unit with the roof being fitted separately. For this build I wanted to try building the sides, ends and roof as one component and have the floor removable.

Taking the basic floor pan the centre line was scribed and a centre point pop marked:

The resulting pop-mark was opened out by drilling up to 2.5mm

The etched ends were snapped off and the tabs cleaned up:

At this point I asked my previous question regarding the folding of the side lips to 90 degrees. I more or less followed the method outlined then starting by scribing the etched fold lines with a knife blade until the result could be seen from the other side:

A folding jig was made up from 2 lengths of scrap timber and screwed together. The outside lip was then clamped in the jig. Somewhere I have a set of Blacksmith bending bars which would need finding and getting the vice out etc and it was actually easier to knock the wooden version together:

The centre section was then bent against the work surface:

A full 90 degrees was not really possible and I would guess I only managed about 85 degrees in the jig:

The last 5 degrees were tweaked using a steel ruler and engineer's square. New fixings to attach the ends to the floorpan were made up from K&S 1/4" angle cut to length then centre popped and drilled 2.5mm:

Using a cocktail stick to align the items a brass M2 nut was soldered to the angle bracket:

The angle bracket was now soldered to the end leaving a 12thou rebate at the bottom so it would sit against the floorpan:

With a little opening out of the holes in the floorpan (elongating with a rat tail needle file) the ends could now be bolted to the floorpan: