Nick Dunhill

Western Thunderer

I was asked to build a pair of EM2s from MSL Hobbies kits. I was delighted as I have lived in Manchester, Sheffield and Rotherham all my life and was/am a big fan of Woodhead and especially the electric locos.

One of the supplied kits was in pristine condition, still in the box with all of the original packing, the other had been opened and fiddled with, and some of the etchings had been damaged at some point. I contacted Mick Davies (Mickoo) who agreed to produce some etchings to replace the badly damaged ones in the kit. It occurred to me that perhaps we should make 2 sets of etches so that both models match each other. Of course the project developed a life of it's own at this stage and Mick actually produced 2 complete bodies with 3D printed parts, more of which later.

Better than any steam loco, including Kings, A4s and Princess Coronations.

I figured that if Mick produced the body etches I could scratchbuild my way round the rest. The EM2 bogies are the same as those fitted to the LMS pioneer locos 10000 and 10001 and MM1 Models agreed to sell me 2 pairs from their kits. I had some pantographs drawn by Adrian Rowland years ago when I scratchbuilt a model of Tommy (EM1 prototype,) and luckily PPD still had the photo etch tool!

The etched body panels arrived from PPD Ltd. One pair of panels had the skeletons of the bodies in nickel-silver and the other pair were brass overlays of all the rivet and strapping detail.

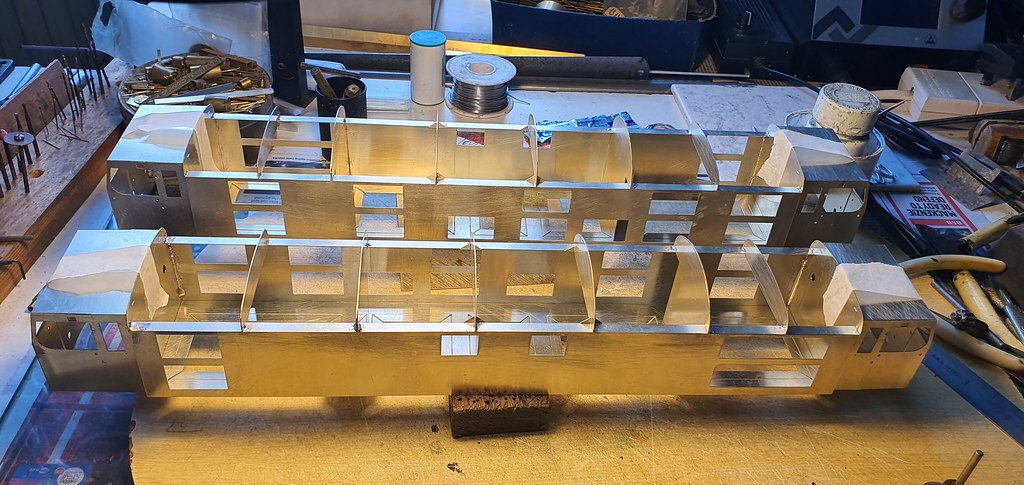

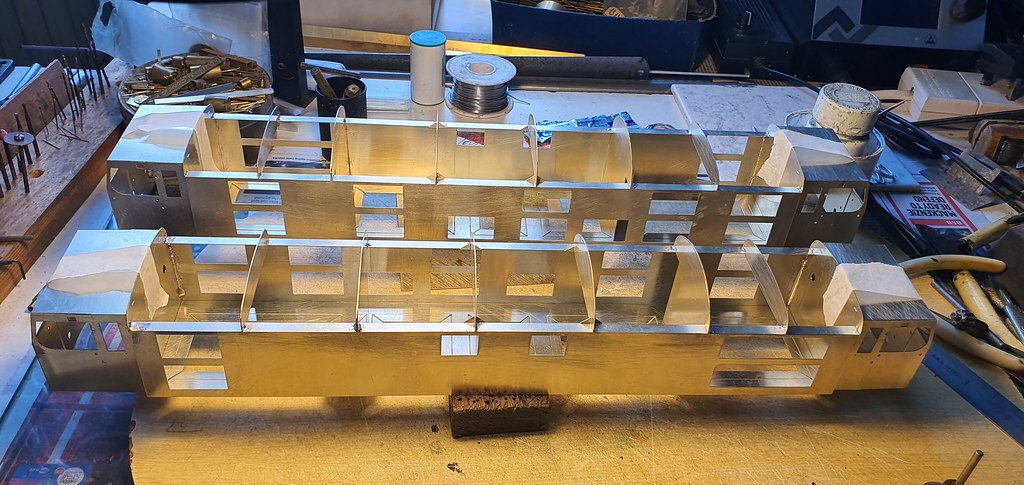

I began by building the bodies. The sides were folded up from the floor after the cantrail rib had been folded at a right angle to the side, bulkheads/formers were installed and the cab rears folded up. The last sentence makes the process sound simple, infact it is feindishly difficult. The fold lines have to be heavily scored to emphasise them, and even then the strips above and below window and louvre appertures bellied out on folding. These had to be encouraged using itterative folding and a hammer to straighten the bellied parts. I used a rectangular dolly to the rear to reshape the sides around the folds and the appertures. I used an actual hammer to build an O gauge loco. The structure has to be constantly checked for squareness and straightness and adjusted where necessary. It has to be able to sit flat on a flatbed and all she sides and ends have to be square and straight.

Next the cabs were folded, and again squareness is paramount! The cabs were then attached to the bodies, I did this on a flat piece of plate glass to make sure the whole thing is true. Again it has to be spot on!

And here are the cabs taped to the bodies prior to fixing. You can see that I've attached the roof ribs.

The process of attaching the overlays then began with the cabs. Much care is needed to align everything then radius the cab corners.

Then a deep breath and form the roof sections. They must be very close to the correct shape before attaching. You cannot use the roof ribs as formers as you will leave a witness mark on the outside.

Lastly the body side overlays can go on. This is the bit where you find out how accurate your fabrication has been. The side overlays have a rebate alont the inside of the top edge that slides satisfyingly over the bottom edges of the roof to disguise it all. I soldered the sides on using 90 deg solder with my iron tip temp turned down a bit to prevent any heat buckling.

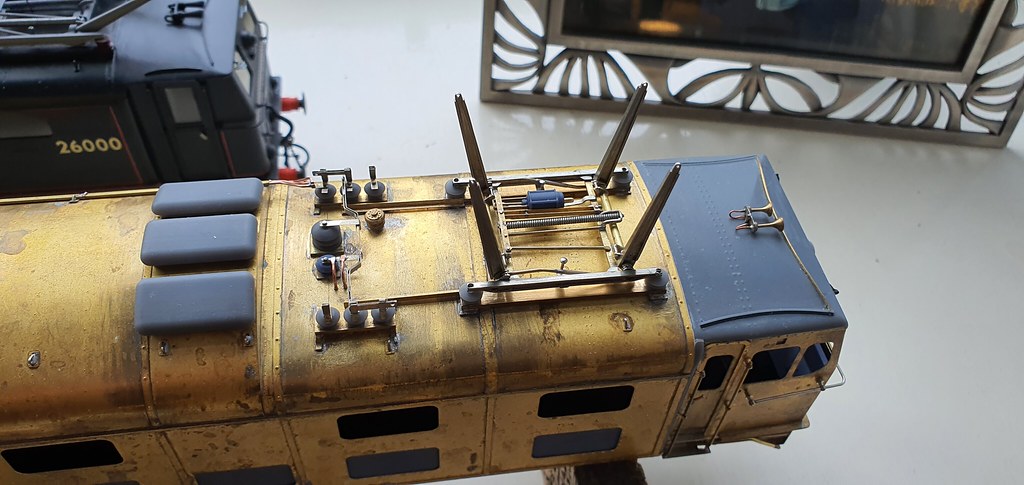

You can see in the above picture that I have added some door details and all the lifting lugs on the roof. There are many many repeats. I also scratchbuilt the solebars and buffer beams. The solebars are cut from 6 x 2 mm brass L-section from Phil Atkinson at Hobby Holidays.

I've built quite a few models of steam locos but building deisel and electric locos is much more difficult because of the accuracy required.

There's a few more pics here; nick dunhill Next week I will do battle with some 3D printed parts.

One of the supplied kits was in pristine condition, still in the box with all of the original packing, the other had been opened and fiddled with, and some of the etchings had been damaged at some point. I contacted Mick Davies (Mickoo) who agreed to produce some etchings to replace the badly damaged ones in the kit. It occurred to me that perhaps we should make 2 sets of etches so that both models match each other. Of course the project developed a life of it's own at this stage and Mick actually produced 2 complete bodies with 3D printed parts, more of which later.

Better than any steam loco, including Kings, A4s and Princess Coronations.

I figured that if Mick produced the body etches I could scratchbuild my way round the rest. The EM2 bogies are the same as those fitted to the LMS pioneer locos 10000 and 10001 and MM1 Models agreed to sell me 2 pairs from their kits. I had some pantographs drawn by Adrian Rowland years ago when I scratchbuilt a model of Tommy (EM1 prototype,) and luckily PPD still had the photo etch tool!

The etched body panels arrived from PPD Ltd. One pair of panels had the skeletons of the bodies in nickel-silver and the other pair were brass overlays of all the rivet and strapping detail.

I began by building the bodies. The sides were folded up from the floor after the cantrail rib had been folded at a right angle to the side, bulkheads/formers were installed and the cab rears folded up. The last sentence makes the process sound simple, infact it is feindishly difficult. The fold lines have to be heavily scored to emphasise them, and even then the strips above and below window and louvre appertures bellied out on folding. These had to be encouraged using itterative folding and a hammer to straighten the bellied parts. I used a rectangular dolly to the rear to reshape the sides around the folds and the appertures. I used an actual hammer to build an O gauge loco. The structure has to be constantly checked for squareness and straightness and adjusted where necessary. It has to be able to sit flat on a flatbed and all she sides and ends have to be square and straight.

Next the cabs were folded, and again squareness is paramount! The cabs were then attached to the bodies, I did this on a flat piece of plate glass to make sure the whole thing is true. Again it has to be spot on!

And here are the cabs taped to the bodies prior to fixing. You can see that I've attached the roof ribs.

The process of attaching the overlays then began with the cabs. Much care is needed to align everything then radius the cab corners.

Then a deep breath and form the roof sections. They must be very close to the correct shape before attaching. You cannot use the roof ribs as formers as you will leave a witness mark on the outside.

Lastly the body side overlays can go on. This is the bit where you find out how accurate your fabrication has been. The side overlays have a rebate alont the inside of the top edge that slides satisfyingly over the bottom edges of the roof to disguise it all. I soldered the sides on using 90 deg solder with my iron tip temp turned down a bit to prevent any heat buckling.

You can see in the above picture that I have added some door details and all the lifting lugs on the roof. There are many many repeats. I also scratchbuilt the solebars and buffer beams. The solebars are cut from 6 x 2 mm brass L-section from Phil Atkinson at Hobby Holidays.

I've built quite a few models of steam locos but building deisel and electric locos is much more difficult because of the accuracy required.

There's a few more pics here; nick dunhill Next week I will do battle with some 3D printed parts.

The EM2 appears to buck the norm, they were chrome but then painted and over time and use would wear, so it's reasonable to expect some areas to wear through and shown the chrome below. The knobs would remain green but the handrail might wear through through use.

The EM2 appears to buck the norm, they were chrome but then painted and over time and use would wear, so it's reasonable to expect some areas to wear through and shown the chrome below. The knobs would remain green but the handrail might wear through through use.