Cheers Ozzy. I think I will go with fitting the ATC gear, since the period the client wants is generally from the point the loco was built until about 1939 or so. I'm pretty sure the equipment would have been fitted during that time, and since I've got the parts in stock...

Earlier this week, my mojo left me. I'm not sure what caused it, but a distracted sleep pattern might not have helped. Anyway, come Thursday afternoon and things began to revive.

Having been bogged down with brake gear - this seems to be a theme with my builds - I decided I needed to have a better idea of where the handbrake column was located. What better excuse to begin work on the bits that sit on the frames?

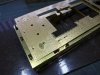

The footplate in this kit is made of a brass fold-up cradle, to which an thinner half-etched overlay is fixed. There's a deal of riveting to do on this overlay, and to make sure I didn't miss any I dabbed around with a black marker pen.

Of course, I punched out the rivets for the lamp brackets (some of those circled), forgetting the SDK includes cast ones...

I have a Graskop riveting tool, with a couple of different sized punches and anvils. What I didn't notice was one of the anvils I used hadn't seated properly, causing the punch to drift slightly on impact. This imparted a slight offset on the resulting rivet, and also caused a subtle bow to the etch. Lesson learned.

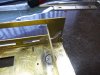

Here's the main footplate cradle. I've bent up the lamp brackets. The etches hadn't quite eaten through parts where there should have been gaps, so I had to run round with a craft knife to open them up. This slight under-etch has had a knock-on where I've had to open up slots and clean back the edges of tabs to ensure they seat nicely.

There are various holes, strategically located to aid soldering (or gluing if you prefer) the overlay to the cradle.

As I said, I forgot I had the cast lamp brackets for this kit. Out with the various tools to clean off the half-etch bracket bases.

The etched lamp brackets can be seen here, including the lamp storage brackets by the leading splasher. Off they come!

Fixing the overlay to the underlying footplate etch, while aided by the holes in the latter, was not my finest hour of soldering. It's a bit messy, but at least it's fixed now.

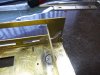

The instructions show the buffer planks etched as part of the basic cradle, designed to fold down and have detailed overlays fixed on top. Of course, this isn't how it works in the kit itself. The buffer planks are separate etches, and the fixing seems to rely on the top edge sitting in a rebate in the footplate, formed from the overlay and cradle, and butt joints on the valance, or hanging bar (as Mr Beare reliably informs me the GWR referred to the stuff under the sides of the footplate). This caused me some oaths of sweariness, as a couple of failed fittings led to me to rethink things. A bad solder joint here would have ramifications if the model was subjected to a bad shunt, or a heavy train snatched the coupling. I wanted to make sure such an eventuality did not occur, so I slept on things.

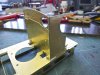

My solution was short lengths of brass angle, fixed to the inside of the hanging bar.

The brackets gave a firmer fixing for the ends of the planks, with some RSU work to get some solder in the top edge along the plank. The cradle bracing struts are not best placed for working on the inside of buffer planks, making it very hard to get a soldering iron, or the RSU probe, in to apply heat. I got there in the end, and after some cleaning up the buffer planks are pretty firmly fixed.

At last, thoughts turned to building things upwards from the footplate.

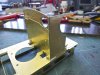

The front and sides of the cab went together very quickly. A basic thick etch carcass is folded up, and front and sides are sweated on top. A couple of errors were noted at this stage: first, the cab handrail fixing holes are etched on the carcass and not on the overlay; second, a line of rivets down the edge of the door opening is missing. These things you fail to spot before you've soldered it all together.

I managed to punch through the handrail holes, but elected to ignore the missing rivets. I could, I suppose, add them cosmetically from spots of PVA or similar before painting begins.

Thoughts turned to the idea of fixing the number plates at this stage of the game. While they could be left until painting is complete, I always fret over the danger of misalignment and subsequent damage to the finish. I have decided to fix the plates while the cab is in parts, so I can get things aligned properly. They can be masked for painting, or at worst cleaned up afterwards. They're still in the pack, so if there are any thoughts on this, shout up!

A dry fit of the cab front and floor. It's starting to look like an engine now.

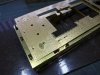

A view of the rear buffer plank. There are half-etch overlays to go down the valances, but they come later in the construction sequence. Sadly, the cradle prevents trial fitting of the footplate to frames, so I can't pose the part-completed model and pretend it's nearly finished.

The value of dry fitting components: I felt the slots in the cab front plate for the wheels could do with widening to match the footplate opening. My worry was the possibility of contact and shorts. A quick pass with the whizzy disc and a file sorted that out.

Now we begin to add details. These are the beading strips for the cab side cut-outs. You'll note there is a hole at one end. The 57xx class doesn't have a handrail inside the door space, so I surmise these have been cut and pasted from another kit etch drawing. They are longer than needed, which is good, so I gently annealed them in a propane torch to make it easier to bend them to shape for the cut out. I tinned the slot, and the edge of the cab frame, and used the RSU to fix them in place, with a little supporting role from the normal iron to make sure it all stayed put.

I couldn't resist. Here we are, posed with the tanks and boiler with the dome and chimney balanced on top. This gives a false sense of being close to the finish, but there remain about half a million little details to add before I can begin to think this build is approaching a conclusion.

This was the state of play last night. The bunker carcass is ready for its overlays, and the cab back panel is in place. Today, I shall finish the bunker and perhaps consider fitting some of the cab interior fittings.

.

.