Heather Kay

Western Thunderer

Simon, thank you for that idea - filed for future reference - and apologies for the delay in responding. Radio silence was mainly due to not having a lot to report that hasn't already been covered in depth on many another thread!

I tackled the loco frames. I admit I don't like steam loco frames. To be fair, I haven't many to my credit, but I always seem to approach the subject with some degree of trepidation. I think it's my generally pessimistic world view. If I think about something, and expect the worst, when it all works out fine it's a definite bonus. If it doesn't work out well, then I hadn't expected better!

Part of the issue with this build was the additional complication of wiggly bits inside the frames. I know they're designed to be pretty much idiot proof, but it was still a worry. Would it all fit in there, bearing in mind the issue recounted some pages back of the wrong sort of slide bars? So, figuring out the inside motion, checking clearances and making a rolling chassis was my goal this week.

First, I tackled my other bête noir, Araldite. My mistake in the past has been to use the wrong sort. Being impatient, I rather take offence at having to wait a day for something to set. I have the same feelings about Milliput, which is also a two-part epoxy. Having had generally poor experiences with the sort of Araldite that's dispensed from a double-barrelled syringe affair, I invested in some proper old-fashioned tubes of the stuff. It was also the lengthy setting variety. My target? Crankpins in the various wheels for builds on the go, and attaching this build's tender body to its floor.

Colour me surprised when it worked as it should! Things seemed to be looking up at last.

Back to the frames, now I had wheels to which I could fit coupling rods…

Having managed to attach the half-etched NS overlays to the already constructed carcass without turning it banana-shaped, it was time to fit the cast hornguides I had half-inched from the 8750 build (being constructed as rigid, you might recall). Obviously, they didn't fit the slots in the frames, so I spent most of Wednesday carefully filing them out. All kinds of things could have gone wrong at this point, but by some miracle I managed to keep things aligned so the cast bearings slid up and down with an axle in place. I forgot to mention that I was doing this stage because I needed at least the leading and centre guides temporarily fitted so I could begin to work out what, if any, clearances were to be had for the internal gubbins.

With hornguides tacked in place with low temp solder - each was marked with corresponding marks on the relevant frame slot, in case there were minor differences in my bodging - I could partially dry assemble an eccentric on the centre axle, and fit the connecting rod. With little fettling, the cast rod parts are a nice friction fit, so no solder was harmed at this stage. My aim is to have the centre axle fitted with all the internal motion including the crosshead so if needs be it can be dropped out of the frames as a single unit.

You may recall the included slide bars and crossheads in this kit are generic items really meant for outside cylinder locos. The slide bars, in particular, I deemed very wrong for this model, although to be fair others have built this loco using the provided parts without issue. Obviously, correcting the overly long slidebars might have a knock-on effect with the throw of the connecting rods, soo this was another thing I was on the lookout for. I haven't mentioned how I'm dealing with slide bars, yet. They're still in the prototype stage, but they do seem to be a working solution. More later.

The crosshead casting needed quite a bit of filing down. As supplied, it wasn't possible to pass the crosshead through the motion bracket, which would be needed if the assembly was to be demountable. Being inside the frames, I felt I could sacrifice a bit of the cast detail on what would be the outside face on an outside cylinder loco. So, I thinned down the main connecting rod bearing and bolt detail, and took a little off the cast oilbox. This made a nice just-about-fit through the motion bracket. Things were looking up. To cut a long, and somewhat rambling, story short, I found I didn't need to remove anything from the hornguides on the front axle. I might just file a small notch, just to be safe, but for now no further surgery is required.

How about getting this perisher on wheels? Right-ho!

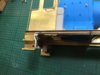

There you go. Now, I am going to put it down to fluke, because the suspension scheme worked, the axles were true, the frames rolled sweetly at first attempt, and only needed two coupling rod bearing holes gently opened a snitch to give a reasonably sweet chassis. I needed a lie down after that, I was so surprised!

There's still a lot to do. There's a ton of detailing, motorising the thing, and working out the demountable underslung spring castings. I set myself a goal of having the frames on wheels by the end of the week, and I managed it.

While I'm here, have a chuckle at the following. As I am replacing the supplied slidebar castings, I needed something to plug holes in the back of the cylinder block. I also needed something to guide the piston rods. I decided I could repurpose the castings so they fitted inside the cylinder block. It needed quite a bit of butchery, and the soldering is not of the highest order, but it worked. Not quite right, I admit, but it works.

From above, what ought to be lost inside the outside cylinder casing on a larger loco is on full view. There are two pairs of slots for the slidebars. Originally these are etched items, but I've found some brass stock that's almost exactly the right width that will serve for new bars. I have a couple of alignment issues to deal with, but that's for another time.

From below, you can see the remains of the cast detailing, plus brass tube guides. I won't win any prizes for the way it looks, but I am considering a cosmetic representation of the cover plate and drain cocks to plug this area. You will note temporary bearing stays, which stop everything falling apart until I get the proper springs organised.

I think that will do on this build for a while. Another build beckons.

I tackled the loco frames. I admit I don't like steam loco frames. To be fair, I haven't many to my credit, but I always seem to approach the subject with some degree of trepidation. I think it's my generally pessimistic world view. If I think about something, and expect the worst, when it all works out fine it's a definite bonus. If it doesn't work out well, then I hadn't expected better!

Part of the issue with this build was the additional complication of wiggly bits inside the frames. I know they're designed to be pretty much idiot proof, but it was still a worry. Would it all fit in there, bearing in mind the issue recounted some pages back of the wrong sort of slide bars? So, figuring out the inside motion, checking clearances and making a rolling chassis was my goal this week.

First, I tackled my other bête noir, Araldite. My mistake in the past has been to use the wrong sort. Being impatient, I rather take offence at having to wait a day for something to set. I have the same feelings about Milliput, which is also a two-part epoxy. Having had generally poor experiences with the sort of Araldite that's dispensed from a double-barrelled syringe affair, I invested in some proper old-fashioned tubes of the stuff. It was also the lengthy setting variety. My target? Crankpins in the various wheels for builds on the go, and attaching this build's tender body to its floor.

Colour me surprised when it worked as it should! Things seemed to be looking up at last.

Back to the frames, now I had wheels to which I could fit coupling rods…

Having managed to attach the half-etched NS overlays to the already constructed carcass without turning it banana-shaped, it was time to fit the cast hornguides I had half-inched from the 8750 build (being constructed as rigid, you might recall). Obviously, they didn't fit the slots in the frames, so I spent most of Wednesday carefully filing them out. All kinds of things could have gone wrong at this point, but by some miracle I managed to keep things aligned so the cast bearings slid up and down with an axle in place. I forgot to mention that I was doing this stage because I needed at least the leading and centre guides temporarily fitted so I could begin to work out what, if any, clearances were to be had for the internal gubbins.

With hornguides tacked in place with low temp solder - each was marked with corresponding marks on the relevant frame slot, in case there were minor differences in my bodging - I could partially dry assemble an eccentric on the centre axle, and fit the connecting rod. With little fettling, the cast rod parts are a nice friction fit, so no solder was harmed at this stage. My aim is to have the centre axle fitted with all the internal motion including the crosshead so if needs be it can be dropped out of the frames as a single unit.

You may recall the included slide bars and crossheads in this kit are generic items really meant for outside cylinder locos. The slide bars, in particular, I deemed very wrong for this model, although to be fair others have built this loco using the provided parts without issue. Obviously, correcting the overly long slidebars might have a knock-on effect with the throw of the connecting rods, soo this was another thing I was on the lookout for. I haven't mentioned how I'm dealing with slide bars, yet. They're still in the prototype stage, but they do seem to be a working solution. More later.

The crosshead casting needed quite a bit of filing down. As supplied, it wasn't possible to pass the crosshead through the motion bracket, which would be needed if the assembly was to be demountable. Being inside the frames, I felt I could sacrifice a bit of the cast detail on what would be the outside face on an outside cylinder loco. So, I thinned down the main connecting rod bearing and bolt detail, and took a little off the cast oilbox. This made a nice just-about-fit through the motion bracket. Things were looking up. To cut a long, and somewhat rambling, story short, I found I didn't need to remove anything from the hornguides on the front axle. I might just file a small notch, just to be safe, but for now no further surgery is required.

How about getting this perisher on wheels? Right-ho!

There you go. Now, I am going to put it down to fluke, because the suspension scheme worked, the axles were true, the frames rolled sweetly at first attempt, and only needed two coupling rod bearing holes gently opened a snitch to give a reasonably sweet chassis. I needed a lie down after that, I was so surprised!

There's still a lot to do. There's a ton of detailing, motorising the thing, and working out the demountable underslung spring castings. I set myself a goal of having the frames on wheels by the end of the week, and I managed it.

While I'm here, have a chuckle at the following. As I am replacing the supplied slidebar castings, I needed something to plug holes in the back of the cylinder block. I also needed something to guide the piston rods. I decided I could repurpose the castings so they fitted inside the cylinder block. It needed quite a bit of butchery, and the soldering is not of the highest order, but it worked. Not quite right, I admit, but it works.

From above, what ought to be lost inside the outside cylinder casing on a larger loco is on full view. There are two pairs of slots for the slidebars. Originally these are etched items, but I've found some brass stock that's almost exactly the right width that will serve for new bars. I have a couple of alignment issues to deal with, but that's for another time.

From below, you can see the remains of the cast detailing, plus brass tube guides. I won't win any prizes for the way it looks, but I am considering a cosmetic representation of the cover plate and drain cocks to plug this area. You will note temporary bearing stays, which stop everything falling apart until I get the proper springs organised.

I think that will do on this build for a while. Another build beckons.

Last edited: