Lancastrian

Western Thunderer

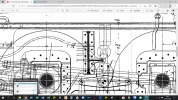

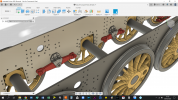

This is where I currently am with the Hughes Compound.

The top drawing shows the frames as set for S7, with the wheelsets drawn to prototype dimensions. Once again, I'm getting to the stage of running out of copies of the original drawings to work from, so will not be able to progress too much further, so I'll return to the Baltic Tank or the Belpaire firebox A class.

Ian

The top drawing shows the frames as set for S7, with the wheelsets drawn to prototype dimensions. Once again, I'm getting to the stage of running out of copies of the original drawings to work from, so will not be able to progress too much further, so I'll return to the Baltic Tank or the Belpaire firebox A class.

Ian