PhilH

Western Thunderer

Two turnouts on the hidden section have been lifted and relaid in a rather awkward location. As related earlier, the turnouts on the hidden section were custom made by Marcway and these have long 'bendy' blades fixed at the crossing end and soldered rigidly at the other end to the tiebar. Not an ideal arrangement as it puts a lot of strain on the soldered joint at the tiebar. The turnout giving access to the low level sidings from the main circuit is the most frequently switched and one blade became detached from the tiebar some time ago and had to be re-soldered, a rather difficult operation because of the limited headroom. After it became detached a second time I decided the only permanent solution was to remove the turnout and hinge the blades as described in the description of the handlaid turnouts. It also seemed wise to do the turnout next to it which gives access to the hidden siding.

The track had been fixed to the cork roadbed with PVA so the turnouts were lifted by sliding a table knife between the ties and the cork and moving it gradually along to break the bond. Fortunately they came away with little damage, just losing some of the PCB ties in the process. Hollows in the cork where the knife had dug in were filled with a polyfilla/sawdust mix. After repair and modification the turnouts were relaid on PVA, with the wiring pre-attached and fed through the existing wiring holes in the process. Locating the tortoise motor operating wires in the tiebars was a bit of a fiddle, but thankfully its all gone back together and hopefully will now be trouble free.

It seems to be the rule that any US narrow gauge layout must have at least one timber trestle, so this layout is no exception. The trestle will be located across the window opening and if I can find a suitable picture or photo the intention is to get this printed on a window blind to form the backdrop to the trestle scene. Anyway that's for the future, the priority now is to get the trestle built. This job has been "starting" for some time with little practical work actually being carried out, so posting it here may encourage a bit more progress - maybe ?

The trestle location with the temporary 'bridge' spanning the gap. Below it on a piece of MDF is marked the track centre line and position of the bents (vertical supports). The plan is to move this forward and build the trestle structure on it, using the existing track alongside - which is on a curve and a gradient - as a reference for the finished alignment and level. When the trestle is complete up to the ties, the temporary bridge can be removed, the trestle slid back into its final position and the track laid across it. That's the plan - for now anyway !

The NorthWest Short Line "chopper" is a tool regularly used by model railroad builders in the US for cutting timbers to length for trestles and similar projects, although there are mixed comments about its usefulness and the size of timber its capable of cutting. So I decided to build my own version and make it perhaps a bit more robust than the NWSL version. Its built mainly from spare materials available to hand - or scrap to most people, I do tend to hoard any bits of timber, metal, spare bolts or screws left over from any job. The only purchased parts were the single edge razor blades which do the actual cutting.

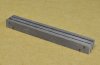

Used with a firm chopping action, i.e. with some force, it gives a reasonably clean square cut - this is 1/4" square basswood.

The track had been fixed to the cork roadbed with PVA so the turnouts were lifted by sliding a table knife between the ties and the cork and moving it gradually along to break the bond. Fortunately they came away with little damage, just losing some of the PCB ties in the process. Hollows in the cork where the knife had dug in were filled with a polyfilla/sawdust mix. After repair and modification the turnouts were relaid on PVA, with the wiring pre-attached and fed through the existing wiring holes in the process. Locating the tortoise motor operating wires in the tiebars was a bit of a fiddle, but thankfully its all gone back together and hopefully will now be trouble free.

It seems to be the rule that any US narrow gauge layout must have at least one timber trestle, so this layout is no exception. The trestle will be located across the window opening and if I can find a suitable picture or photo the intention is to get this printed on a window blind to form the backdrop to the trestle scene. Anyway that's for the future, the priority now is to get the trestle built. This job has been "starting" for some time with little practical work actually being carried out, so posting it here may encourage a bit more progress - maybe ?

The trestle location with the temporary 'bridge' spanning the gap. Below it on a piece of MDF is marked the track centre line and position of the bents (vertical supports). The plan is to move this forward and build the trestle structure on it, using the existing track alongside - which is on a curve and a gradient - as a reference for the finished alignment and level. When the trestle is complete up to the ties, the temporary bridge can be removed, the trestle slid back into its final position and the track laid across it. That's the plan - for now anyway !

The NorthWest Short Line "chopper" is a tool regularly used by model railroad builders in the US for cutting timbers to length for trestles and similar projects, although there are mixed comments about its usefulness and the size of timber its capable of cutting. So I decided to build my own version and make it perhaps a bit more robust than the NWSL version. Its built mainly from spare materials available to hand - or scrap to most people, I do tend to hoard any bits of timber, metal, spare bolts or screws left over from any job. The only purchased parts were the single edge razor blades which do the actual cutting.

Used with a firm chopping action, i.e. with some force, it gives a reasonably clean square cut - this is 1/4" square basswood.

Last edited:

. For a nearly 50 year old model its in pretty good condition with no wheel wear and a moderate amount of tarnish. I assume its spent most of its life in a display case rather than the box, as the original box has gone missing.

. For a nearly 50 year old model its in pretty good condition with no wheel wear and a moderate amount of tarnish. I assume its spent most of its life in a display case rather than the box, as the original box has gone missing.

. If I find it sufficiently annoying as it is I may have another go. I did remove some paint from the yellow planking with wire wool to show traces of the previously stained weathered wood underneath, but it doesn’t show in the photo. I think two coats of the yellow was one too many

. If I find it sufficiently annoying as it is I may have another go. I did remove some paint from the yellow planking with wire wool to show traces of the previously stained weathered wood underneath, but it doesn’t show in the photo. I think two coats of the yellow was one too many