You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Finney Battle of Britain

- Thread starter mickoo

- Start date

mickoo

Western Thunderer

JB, you're welcome  Give me a shout when you get to your GE rendition as I have some info in mags that might help.

Give me a shout when you get to your GE rendition as I have some info in mags that might help.

Moving on, cab detailing, have to say, bleedin nightmare, so fiddly and so blessed small! But get there in the end I did, still a fair bit of solder to clean up, mostly own goals as soldering very small bits to very large bits required a small tip and a lot of heat, which didn't work. So in a fit of rage I put the biggest tip on, twice as much solder as required whacked the temp up to 400 and just bombed it, that made it stick. I really need a RSU for this sort of work I think.

The photos, general walk around first.

Cab roof looks tipped up at rear end, it isn't, just lens distortion.

Seagull view, huge great hole down the chimney, needs a light blocker put in with basic shape of exhaust jets and pipework etc.

Rear end.

Cruel close up of cab rear end, need to work on the fixings here to square it all up with the drag beam.

Roof profile check

Works for me

Cab profile check

Again, pretty much spot on.

On to the casing, deflectors and other sundry covers next.

MD

Give me a shout when you get to your GE rendition as I have some info in mags that might help.

Give me a shout when you get to your GE rendition as I have some info in mags that might help.Moving on, cab detailing, have to say, bleedin nightmare, so fiddly and so blessed small! But get there in the end I did, still a fair bit of solder to clean up, mostly own goals as soldering very small bits to very large bits required a small tip and a lot of heat, which didn't work. So in a fit of rage I put the biggest tip on, twice as much solder as required whacked the temp up to 400 and just bombed it, that made it stick. I really need a RSU for this sort of work I think.

The photos, general walk around first.

Cab roof looks tipped up at rear end, it isn't, just lens distortion.

Seagull view, huge great hole down the chimney, needs a light blocker put in with basic shape of exhaust jets and pipework etc.

Rear end.

Cruel close up of cab rear end, need to work on the fixings here to square it all up with the drag beam.

Roof profile check

Works for me

Cab profile check

Again, pretty much spot on.

On to the casing, deflectors and other sundry covers next.

MD

mickoo

Western Thunderer

Build date +52

I set a target of sundown this evening to get as much done pre Telford, bar a few details on the casing and actually gluing the covers (double sided tape is a photographers secret weapon) it's as far as I'm going until after the show.

I have tonight and all of tomorrow to try and get at least some of the other stuff done.

Anyway, with the sun well below the horizon I bagged this last shot in near darkness...I do like this sensor on the big camera, great for low light. I'll take some more tomorrow when the sun is up and write some details up about a few bits and pieces.

If I get a chance I'll add the lamps on the deflectors and casing cover hand rails and clips as well as the whistle and give it a final clean before packing it away for the show.

Still a long way to go for completion though.

MD

T-2

I set a target of sundown this evening to get as much done pre Telford, bar a few details on the casing and actually gluing the covers (double sided tape is a photographers secret weapon) it's as far as I'm going until after the show.

I have tonight and all of tomorrow to try and get at least some of the other stuff done.

Anyway, with the sun well below the horizon I bagged this last shot in near darkness...I do like this sensor on the big camera, great for low light. I'll take some more tomorrow when the sun is up and write some details up about a few bits and pieces.

If I get a chance I'll add the lamps on the deflectors and casing cover hand rails and clips as well as the whistle and give it a final clean before packing it away for the show.

Still a long way to go for completion though.

MD

T-2

mickoo

Western Thunderer

Dan Randall

Western Thunderer

Mick, considering you only started this thread on 10th July, that's pretty rapid progress!  It looks excellent and I look forward to seeing it in the flesh tomorrow.

It looks excellent and I look forward to seeing it in the flesh tomorrow.

Regards

Dan

It looks excellent and I look forward to seeing it in the flesh tomorrow.

It looks excellent and I look forward to seeing it in the flesh tomorrow.

Regards

Dan

mickoo

Western Thunderer

Thank you for the comments and popping by to say hello.I saw this today in the flesh and must say it's every bit as impressive close up.

Good to chat to part of the Finney7 collective. A big thank you for the help and advice with horn blocks for my WR 1366 dock tank chassis rebuild.

Re hornguides, you're more than welcome, don't be shy with photos of your build, it sounded really interesting what you were going to achieve

MD

Pencarrow

Western Thunderer

Thank you for the comments and popping by to say hello.

Re hornguides, you're more than welcome, don't be shy with photos of your build, it sounded really interesting what you were going to achieve

MD

Thanks Mick. Here's a few of the body. Started nearly 3 years ago as a first ever kit kit loco. Not the best choice and a painful way to learn that there's a wide variance in the quality of kits. It was abandoned two years ago whilst I went away, licked my wounds, and built a couple of better thought out offerings with higher quality castings. I've recently picked it back up again and been busy correcting further kit errors and some of my own kack-handedness.

mickoo

Western Thunderer

Saw the Bullied today...

Definitely on the wish list... Oh bu**er it!

JB.

7mmMick

Western Thunderer

Now then Chris,

As Mick says, a cracking build. Thanks also from me for coming and saying hello. I look forward to a Workbench thread as what you're doing looks great and I could pick up some tips as well.I know my interests are NER but anything that worked docks, small tank engine types are right up my street

Best regards Mick

As Mick says, a cracking build. Thanks also from me for coming and saying hello. I look forward to a Workbench thread as what you're doing looks great and I could pick up some tips as well.I know my interests are NER but anything that worked docks, small tank engine types are right up my street

Best regards Mick

Mr Grumpy

Western Thunderer

I love the 1366 tanks! I very nearly got sucked in to buying one, but luckily pulled out. I hope you get her up and running and look forward to seeing the end result. Mine would have been in land fill by now !Thanks Mick. Here's a few of the body. Started nearly 3 years ago as a first ever kit kit loco. Not the best choice and a painful way to learn that there's a wide variance in the quality of kits. It was abandoned two years ago whilst I went away, licked my wounds, and built a couple of better thought out offerings with higher quality castings. I've recently picked it back up again and been busy correcting further kit errors and some of my own kack-handedness.

View attachment 58560

View attachment 58558

(Sorry for the thread hijack Mick )

mickoo

Western Thunderer

Despite spending most of the day musing over toys bought at Telford, I did achieve some progress on the BLP.

All of the wheels were cleaned before the show, yet four days later they were beginning to rust badly, so I had to do something about it, blackening was the answer and with results bordering on marginal before, I set about the task again.

This time was slightly different, instead of applying the solution neat with a cotton bud I dropped them completely in a diluted solution, no idea of the ratio but 5:1 - 6:1 or something. Anyway, peering into the tub they started to darken and at a given moment I pulled them out and dried them.

At this point they continued to darken rapidly and then develop a greenish brown fur which when rubbed started to expose the bright metal underneath. So a quick wash in warm water and a clean with cloth I was back to the start with moderately darkened wheels. Strangely the wash in water enriched the colour and seemed to make the processed items more durable.

The second attempt was slightly different, observing what had gone on before, it appears that the darkening process really takes hold once the item is exposed to air after it's bath and then firms up when washed with water. So into the blackening solution bath they went again and this time removed out onto a paper towel to get rid of most of the excess water. Then it was straight into another bowl of clean water, where they sat for a few minutes whilst I prepared the final stage.

Final stage was to squirt some oil onto a surface and liberally coat a cotton bud with said oil, removing the wheels from the water, a quick dry and gentle rub followed by a good drubbing of oil. This I left for five minutes before wiping the excess off and refitted to the axles, also treated the same way.

Et voila, black wheels and axles, finally!

The treads need a little polish but I'll leave that until right at the end, so as to preserve the darkening layer for as long as possible; the thin layer of oil makes for a superb dust magnet

I'll do the driving wheels tomorrow and think about applying some brass blackening to the brass boss to tone it down, that'll have to be the cotton bud method but I have a plan I'll try that replicates the above minus the bath affair.

So, what was today's lesson, dilute your blacking agent, do not expose the component to the atmosphere with the agent on for too long (max 20-30 seconds) before soaking in water, apply a protective layer (oil) as soon as washed and dry.

We'll see if these last a little longer before corrosion sets in.

MD

All of the wheels were cleaned before the show, yet four days later they were beginning to rust badly, so I had to do something about it, blackening was the answer and with results bordering on marginal before, I set about the task again.

This time was slightly different, instead of applying the solution neat with a cotton bud I dropped them completely in a diluted solution, no idea of the ratio but 5:1 - 6:1 or something. Anyway, peering into the tub they started to darken and at a given moment I pulled them out and dried them.

At this point they continued to darken rapidly and then develop a greenish brown fur which when rubbed started to expose the bright metal underneath. So a quick wash in warm water and a clean with cloth I was back to the start with moderately darkened wheels. Strangely the wash in water enriched the colour and seemed to make the processed items more durable.

The second attempt was slightly different, observing what had gone on before, it appears that the darkening process really takes hold once the item is exposed to air after it's bath and then firms up when washed with water. So into the blackening solution bath they went again and this time removed out onto a paper towel to get rid of most of the excess water. Then it was straight into another bowl of clean water, where they sat for a few minutes whilst I prepared the final stage.

Final stage was to squirt some oil onto a surface and liberally coat a cotton bud with said oil, removing the wheels from the water, a quick dry and gentle rub followed by a good drubbing of oil. This I left for five minutes before wiping the excess off and refitted to the axles, also treated the same way.

Et voila, black wheels and axles, finally!

The treads need a little polish but I'll leave that until right at the end, so as to preserve the darkening layer for as long as possible; the thin layer of oil makes for a superb dust magnet

I'll do the driving wheels tomorrow and think about applying some brass blackening to the brass boss to tone it down, that'll have to be the cotton bud method but I have a plan I'll try that replicates the above minus the bath affair.

So, what was today's lesson, dilute your blacking agent, do not expose the component to the atmosphere with the agent on for too long (max 20-30 seconds) before soaking in water, apply a protective layer (oil) as soon as washed and dry.

We'll see if these last a little longer before corrosion sets in.

MD

Pencarrow

Western Thunderer

Despite spending most of the day musing over toys bought at Telford, I did achieve some progress on the BLP.

All of the wheels were cleaned before the show, yet four days later they were beginning to rust badly, so I had to do something about it, blackening was the answer and with results bordering on marginal before, I set about the task again.

This time was slightly different, instead of applying the solution neat with a cotton bud I dropped them completely in a diluted solution, no idea of the ratio but 5:1 - 6:1 or something. Anyway, peering into the tub they started to darken and at a given moment I pulled them out and dried them.

At this point they continued to darken rapidly and then develop a greenish brown fur which when rubbed started to expose the bright metal underneath. So a quick wash in warm water and a clean with cloth I was back to the start with moderately darkened wheels. Strangely the wash in water enriched the colour and seemed to make the processed items more durable.

The second attempt was slightly different, observing what had gone on before, it appears that the darkening process really takes hold once the item is exposed to air after it's bath and then firms up when washed with water. So into the blackening solution bath they went again and this time removed out onto a paper towel to get rid of most of the excess water. Then it was straight into another bowl of clean water, where they sat for a few minutes whilst I prepared the final stage.

Final stage was to squirt some oil onto a surface and liberally coat a cotton bud with said oil, removing the wheels from the water, a quick dry and gentle rub followed by a good drubbing of oil. This I left for five minutes before wiping the excess off and refitted to the axles, also treated the same way.

View attachment 58740

Et voila, black wheels and axles, finally!

The treads need a little polish but I'll leave that until right at the end, so as to preserve the darkening layer for as long as possible; the thin layer of oil makes for a superb dust magnet

I'll do the driving wheels tomorrow and think about applying some brass blackening to the brass boss to tone it down, that'll have to be the cotton bud method but I have a plan I'll try that replicates the above minus the bath affair.

So, what was today's lesson, dilute your blacking agent, do not expose the component to the atmosphere with the agent on for too long (max 20-30 seconds) before soaking in water, apply a protective layer (oil) as soon as washed and dry.

We'll see if these last a little longer before corrosion sets in.

MD

You have my sympathies. Blackening Slaters wheels and getting them to stop rusting is something I've had a lot of trouble with.

Pencarrow

Western Thunderer

Now then Chris,

As Mick says, a cracking build. Thanks also from me for coming and saying hello. I look forward to a Workbench thread as what you're doing looks great and I could pick up some tips as well.I know my interests are NER but anything that worked docks, small tank engine types are right up my street

Best regards Mick

Apologies for the intrusion but there's a summary of some of my projects here: 7mm - Pencarrow Bridge | Western Thunder

mickoo

Western Thunderer

A bag of white metal castings arrived this morning, a loan from a kind benefactor to allow the instruction build to progress without delay, thank you

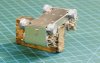

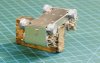

First off was the Delta truck to be completed

Then the front bogie

Followed this evening by the cylinder assembly

Sadly the lighting isn't particularly good, a high ASA making for grainy shots, apologies for the solder floods in places, in my eagerness to fit the white metal castings I forgot about the oil pipes, specifically the Seahorse shaped one for the stuffing gland, to say soldering that in was difficult is a bit of an understatement.

What I should of done was bend the oil pipe roughly to shape, solder to the stuffing gland fitting, then add the white metal valve guide cover and oil pot, but I didn't, so a 15 minute job took a couple of hours of fiddling and swearing.

One thing I did notice, is that Bulleid Pacifics have steam vent pipes from the valve piston as well as the main piston, I'd not clocked why there where three steam cocks down below earlier, so that pipework was added in. I cannot recall seeing this feature on other engines, most have two cylinder cocks for the main piston only.

I'll try and pose the cylinders with the slide bar assembly tomorrow in the day light for a better picture, shame is, most of this is near invisible once the body is added.

MD

First off was the Delta truck to be completed

Then the front bogie

Followed this evening by the cylinder assembly

Sadly the lighting isn't particularly good, a high ASA making for grainy shots, apologies for the solder floods in places, in my eagerness to fit the white metal castings I forgot about the oil pipes, specifically the Seahorse shaped one for the stuffing gland, to say soldering that in was difficult is a bit of an understatement.

What I should of done was bend the oil pipe roughly to shape, solder to the stuffing gland fitting, then add the white metal valve guide cover and oil pot, but I didn't, so a 15 minute job took a couple of hours of fiddling and swearing.

One thing I did notice, is that Bulleid Pacifics have steam vent pipes from the valve piston as well as the main piston, I'd not clocked why there where three steam cocks down below earlier, so that pipework was added in. I cannot recall seeing this feature on other engines, most have two cylinder cocks for the main piston only.

I'll try and pose the cylinders with the slide bar assembly tomorrow in the day light for a better picture, shame is, most of this is near invisible once the body is added.

MD