Gadgie

Western Thunderer

A little more progress to report. I left the cranks attached to their sprues, which meant that fitting them to the axles and quartering was a little easier than it would have been otherwise.

Initial fitting of the coupling rods was somewhat troublesome. The chassis ran perfectly with the rods fitted the wrong way round, but when fitted correctly there was binding and tightness once per revolution. It turned out that this was being caused not by faulty quartering, but by a rough edge on the rivet at the rear of the coupling rods, which was shaving microscopic bits of black plastic off the central crank. Ten seconds with a file and everything was tickety boo.

Then I decided to loosen up the rather stiff screw coupling on the front bufferbeam. It promptly broke. I thought that the hook might pull out, but that broke off too. OK, I thought, I'll drill it out and replace it with a Lanarkshire Models hook. I started the hole in the broken end of the hook with a drill in a pin vice. I then decided to continue with a minidrill to save time. Big mistake. I had assumed the whole buffer beam was moulded in whatever metal Hornby use for their chassis. I was wrong. It is plastic, the drill slipped, and ended up with a nasty hole in the wrong place (at around 7 o'clock).

After some judicious excavation with a variety of tools, I managed to extract the broken off end of the hook, and drill a hole in the correct place (by hand). A Lanarkshire hook has been duly inserted, and secured (so far) with T-7000 adhesive. I bought this a while ago from eBay because my son had dropped his phone (sigh), and it was recommended for fitting a new phone screen, which is still in place. The glue is very strong, dries quickly, and being black, is fairly unobtrusive. It does string a bit, and may contain nasty chemicals, but I quite like it for jobs like this because it also acts as a filler.

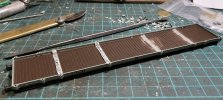

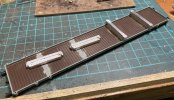

So the next jobs are fitting hinge straps, and renumbering. Of course one option would be to buy a replacement body -- Hornby do a version of the 08 with hinge straps -- but I have decided to go with the Tim Shackleton approach, using etched riveted strip. These strips are often a bit of pain to paint, so I have attached them to some masking tape to prevent them from being blown away by Halfords etching primer. I think this might make it easier to cut them to length, too.

Next job was removing the old number and BR logo, since a more diligent search of Flickr has also turned up a picture of D3455 as 08378, but still in green livery, with a BR crest on the bonnet doors rather than the cabinet as in the Hornby model. I came across a video tutorial recently describing removal of printed numbers using microsol and magic tape. I'm delighted to say it worked very well, with the big advantage that no abrasive is required, so the paintwork stays nice and smooth. Complete removal did require a few applications of microsol and tape, but this methods seems much better than the alternatives.

Initial fitting of the coupling rods was somewhat troublesome. The chassis ran perfectly with the rods fitted the wrong way round, but when fitted correctly there was binding and tightness once per revolution. It turned out that this was being caused not by faulty quartering, but by a rough edge on the rivet at the rear of the coupling rods, which was shaving microscopic bits of black plastic off the central crank. Ten seconds with a file and everything was tickety boo.

Then I decided to loosen up the rather stiff screw coupling on the front bufferbeam. It promptly broke. I thought that the hook might pull out, but that broke off too. OK, I thought, I'll drill it out and replace it with a Lanarkshire Models hook. I started the hole in the broken end of the hook with a drill in a pin vice. I then decided to continue with a minidrill to save time. Big mistake. I had assumed the whole buffer beam was moulded in whatever metal Hornby use for their chassis. I was wrong. It is plastic, the drill slipped, and ended up with a nasty hole in the wrong place (at around 7 o'clock).

After some judicious excavation with a variety of tools, I managed to extract the broken off end of the hook, and drill a hole in the correct place (by hand). A Lanarkshire hook has been duly inserted, and secured (so far) with T-7000 adhesive. I bought this a while ago from eBay because my son had dropped his phone (sigh), and it was recommended for fitting a new phone screen, which is still in place. The glue is very strong, dries quickly, and being black, is fairly unobtrusive. It does string a bit, and may contain nasty chemicals, but I quite like it for jobs like this because it also acts as a filler.

So the next jobs are fitting hinge straps, and renumbering. Of course one option would be to buy a replacement body -- Hornby do a version of the 08 with hinge straps -- but I have decided to go with the Tim Shackleton approach, using etched riveted strip. These strips are often a bit of pain to paint, so I have attached them to some masking tape to prevent them from being blown away by Halfords etching primer. I think this might make it easier to cut them to length, too.

Next job was removing the old number and BR logo, since a more diligent search of Flickr has also turned up a picture of D3455 as 08378, but still in green livery, with a BR crest on the bonnet doors rather than the cabinet as in the Hornby model. I came across a video tutorial recently describing removal of printed numbers using microsol and magic tape. I'm delighted to say it worked very well, with the big advantage that no abrasive is required, so the paintwork stays nice and smooth. Complete removal did require a few applications of microsol and tape, but this methods seems much better than the alternatives.