John Duffy

Western Thunderer

Following a recent conversation with a friend where we were looking at the need for some North British bolsters, I have managed to get the body parts prepared. Other fittings are available and the bolsters themselves can be fabricated. The one thing that I cannot see a way to produce is the buffer casing.

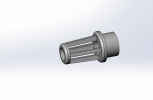

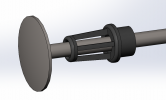

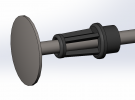

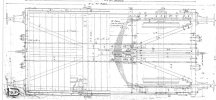

These were of extra length and had 4 fins, as per;

There is a 4mm drawing available.

Would any of our 3D printing experts be willing to assist in producing these? Perhaps in exchange for some body parts in 4 or 7mm?

Any help will be appreciated. DM if interested.

Thanks

John

These were of extra length and had 4 fins, as per;

There is a 4mm drawing available.

Would any of our 3D printing experts be willing to assist in producing these? Perhaps in exchange for some body parts in 4 or 7mm?

Any help will be appreciated. DM if interested.

Thanks

John

, but wrong, tant pis. It’s not a big job to alter them, happily.

, but wrong, tant pis. It’s not a big job to alter them, happily.