Andy Ross

Active Member

Hunslet Works update.

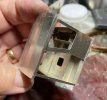

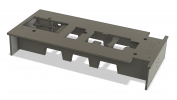

After a view false start I have managed to put together the second bridge structure.

Originally this was to cover the crane tracks that ran from the machine shop to the boiler shop.

By myth time this was still in use but only to bring items out of the machine shop. The doors into the boiler shop had been bricked up and some building as added. all that is left is the upper lifting door but this was locked in place and built unto as can be seen in the photo below.

I have included photos of the buildings before the bridge section was added.

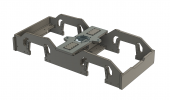

The upper doorway was fragile and I broke the first one so when cut is has a sacrificial support frame which will be removed to add the door frame.

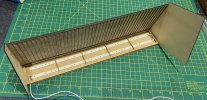

I am not sure how much will be visible at exhibitions under the roof so at the moment there is a representation of the frame work and trusses all laser cut. There is some overlays and a couple of steel columns to add that go down to the floor which I will probably get etched.

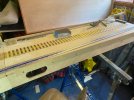

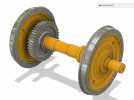

The rest of the photos are just general views.

This is as far as I am going before the Swindon show next weekend.

If you would like to see the progress in the flesh, then please come along to the Swindon Railway Festival at the steam museum on the 9th and 10th September. Please say hello.

Andy

After a view false start I have managed to put together the second bridge structure.

Originally this was to cover the crane tracks that ran from the machine shop to the boiler shop.

By myth time this was still in use but only to bring items out of the machine shop. The doors into the boiler shop had been bricked up and some building as added. all that is left is the upper lifting door but this was locked in place and built unto as can be seen in the photo below.

I have included photos of the buildings before the bridge section was added.

The upper doorway was fragile and I broke the first one so when cut is has a sacrificial support frame which will be removed to add the door frame.

I am not sure how much will be visible at exhibitions under the roof so at the moment there is a representation of the frame work and trusses all laser cut. There is some overlays and a couple of steel columns to add that go down to the floor which I will probably get etched.

The rest of the photos are just general views.

This is as far as I am going before the Swindon show next weekend.

If you would like to see the progress in the flesh, then please come along to the Swindon Railway Festival at the steam museum on the 9th and 10th September. Please say hello.

Andy

Attachments

Last edited: