Ian_C

Western Thunderer

...The Bangles, 2011.

Yes, finally I've made a start on the tender. There are still a few tidy up jobs on the loco, but I'm not in the mood right now and want to press on. I'm going to put the electrical pick ups on the tender so it helps a lot if all of the wheels contact the rails at the same time. As with the loco, the compensation arrangement on the tender is goofy. It's what you'd call 'statically indeterminate' if you wanted to impress somebody with your engineering knowledge. Or, to use the popular furniture analogy, if compensation is meant to give you the equivalent of a three legged stool on the uneven kitchen floor, the kit gives you a four legged chair that rocks from corner to corner. There's no cross chassis compensation. I'd imagined that I'd simply (!) redesign the inner chassis with sprung axle boxes or CSB...or something. Plus I was going to use insulated split axles and avoid wiper contacts. Ambition is an admirable thing. When I looked at the chassis etches and the instructions it was hard to see how it all goes together and comes apart again with brake linkages and water scoop gear strewn all over. Overwhelmed. Where on earth do you start?

I've decided to build according to the instructions up to the point I can see how all the gubbins fits together, then work out what changes I want to make. The tender instructions are patchy (but Mr MOK made that clear at time of purchase, so no surprises). The David Coulshed (circulating somewhere on WT) annotated version adds some useful notes and is worth obtaining. The Wild Swan 8F Loco Profile has no drawings of the 4,000 gallon tender, but they are present in Loco Profile 5 - The Mixed Traffic Class 5s - Nos. 5000-5224.

The initial build offers a respite from the mental toil of design and scratchbuild, and substitutes the tedium of filing off etch cusps.

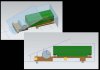

The MOK tab & slot fabrication makes life very easy. There are a couple of misplaced tabs on one of the chassis end sub assemblies but it's easy enough to file them off and position the parts by eye. Very quickly you get to this stage...

Naturally there's a puzzle to solve. The lower crossmembers really do have to be removable to allow the fitting and removal of the inner working chassis. It took me a while to realise that one crossmember is flanges up and the other is flanges down. I discovered this when examining the drawings in the Wild Swan book, but it was stated in the instructions if I'd cared to read them! How to secure them without fasteners showing is the challenge. I don't know what the kit design intention was, but this is my solution...

There didn't seem to be any point in using all of the fixing points and doubling up the amount of work.

The inner chassis is the next job, along with a look at the compensation problem.

This episode brought to you with help from Bedsofaland, 9 Lazy 9, 2010

Yes, finally I've made a start on the tender. There are still a few tidy up jobs on the loco, but I'm not in the mood right now and want to press on. I'm going to put the electrical pick ups on the tender so it helps a lot if all of the wheels contact the rails at the same time. As with the loco, the compensation arrangement on the tender is goofy. It's what you'd call 'statically indeterminate' if you wanted to impress somebody with your engineering knowledge. Or, to use the popular furniture analogy, if compensation is meant to give you the equivalent of a three legged stool on the uneven kitchen floor, the kit gives you a four legged chair that rocks from corner to corner. There's no cross chassis compensation. I'd imagined that I'd simply (!) redesign the inner chassis with sprung axle boxes or CSB...or something. Plus I was going to use insulated split axles and avoid wiper contacts. Ambition is an admirable thing. When I looked at the chassis etches and the instructions it was hard to see how it all goes together and comes apart again with brake linkages and water scoop gear strewn all over. Overwhelmed. Where on earth do you start?

I've decided to build according to the instructions up to the point I can see how all the gubbins fits together, then work out what changes I want to make. The tender instructions are patchy (but Mr MOK made that clear at time of purchase, so no surprises). The David Coulshed (circulating somewhere on WT) annotated version adds some useful notes and is worth obtaining. The Wild Swan 8F Loco Profile has no drawings of the 4,000 gallon tender, but they are present in Loco Profile 5 - The Mixed Traffic Class 5s - Nos. 5000-5224.

The initial build offers a respite from the mental toil of design and scratchbuild, and substitutes the tedium of filing off etch cusps.

The MOK tab & slot fabrication makes life very easy. There are a couple of misplaced tabs on one of the chassis end sub assemblies but it's easy enough to file them off and position the parts by eye. Very quickly you get to this stage...

Naturally there's a puzzle to solve. The lower crossmembers really do have to be removable to allow the fitting and removal of the inner working chassis. It took me a while to realise that one crossmember is flanges up and the other is flanges down. I discovered this when examining the drawings in the Wild Swan book, but it was stated in the instructions if I'd cared to read them! How to secure them without fasteners showing is the challenge. I don't know what the kit design intention was, but this is my solution...

There didn't seem to be any point in using all of the fixing points and doubling up the amount of work.

The inner chassis is the next job, along with a look at the compensation problem.

This episode brought to you with help from Bedsofaland, 9 Lazy 9, 2010