Not quite a week since my last post, but quite a bit to catch up with. While I was determined to crack on with the task, it is probably true to say I wasn't really in the best place, either mentally or physically as it happened!

The effort required to cut and fettle eight sections out of some 20mm steel angle surprised and frustrated me a little...

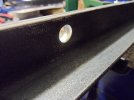

By the time I drilled four of them out I'd had quite enough of that!

Incidentally, the sharp eyed amongst you might have noticed that the twin holes are offset, or oriented towards one edge on each angle! That was deliberate, in order to make allowance for the angle at the rear of the solebars... At least, that was the intention anyway! I still managed to get it wrong though!

I had completely forgotten about the nut... After a whole lot of faffing about, the top bolts would still not settle flat on three out of the four brackets!

Worse was to come...!

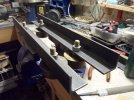

I was concerned about structural strength of the underframes, particularly bearing in mind that the wheels are bolted to the outside of the solebars - with no axles in between to resist twisting under load. I had already decided to screw the bars onto substantial timber "joists", which when firmly attached under the floors, should prove to be strong enough. (?)

I did say I was not thinking clearly enough though?

Having bolted up the first pair of frames worth, it finally dawned that I had cut every one of those wretched angles short - only covering the steel sections, and not all the way up to include the timbers. The issue was further compounded by having now chopped up too much of my remaining angle held in stock!

I could have cried at the prospect of having to do it all over again, let alone the waste of materials!

My bus pass is taking a right hammering with all these unscheduled trips to the nearest DIY emporium - although the loaded returns can be amusing, and almost guaranteed to raise the odd eyebrow! I can almost hear the conversation in the crew rooms:

"Hey Rich, I 'ad your ol' dad on my bus earlier - an' you'll never guess what he tried to get on with this time?!"

I got away with it again - and after much huffing and puffing, the above and following two images shows how the brackets were meant to be in the first place!

By the way, the "joists" were only located for trial purposes when photographed - and that turned out to be just as well too...!

Oh, the errors were turning into a catalogue!

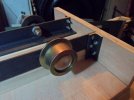

I really thought I had been so careful to insure that the solebars were square, accurately and centrally marked out - and that all the holes in the headstocks were properly aligned - particularly as the arrangement has a critical bearing on maintaining the precise back-to-back measurements! Amazingly, I had got that bit pretty much spot on by the close of play (?)

The following morning I decided to test the beastie out on the track...

It ran lovely and smooth - until it reached the points! It wouldn't go through them without derailing - every damned time!

Checked the BtoB's again... but still an absolutely perfect 121mm! What the hell was going on?!

After spending what seemed like an age down on my knees, pushing the thing to and fro, the lights eventually came back on! I had, quite naturally been assuming that the BtoB was an inviolate rule. However, the steel flanges on these new wheels are significantly narrower than those of our existing stock - simply meaning that the wheels can laterally travel further over before there is any contact with the check rail!

There was only one way to confirm the notion - and that was by stripping the chassis back down, and then clamping up to increase the width of the solebars by increments, then repeatedly testing to see if it would work!

It did in the end - thereafter running consistently sweetly at an astonishing increase to 128mm back-to-back!

Fortuitously, I had already cut the additional, second floor and pair of headstocks from the same piece of ply on my "el cheapo" bench saw, (thus at least giving myself half a chance that the parts might actually match each other) so I was able to drill and set up the second, unsullied pair of headstocks to the revised dimensions. My reasoning was that the originals could be dowelled and re-drilled later on.

Really! I mean, what a dozy twit am I..?!

A lovely, pristine chassis might now glide impeccably through the P and C's...

When all I had to do was slip some 12mm washers between the frames and axle shoulders to achieve the same effect!

That didn't occur to me until the following day!!

There is one little saving grace concerning the waste material from earlier though:

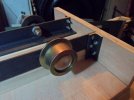

By opening out one hole in each of the previously regarded redundant angles, along with a few minutes worth of re-shaping, I now have a functional set of simple couplings - that match both loco's bar-and-pin arrangement!

Finally, just to prove it:

The ride is quite hard, hence the cushion, and joyously "lively" behind the "speeder", thanks mainly to the small wheel diameter with narrow flanges and short (9 inch) wheelbase, allowing the wagon to take the infamous top curve with barely noticeable resistance. It is also amazingly stable!

It has also proved beyond any doubts I may have harboured, that it will be quite safe to go ahead and design a seat for riding side-saddle! Past experience reveals that might be a boon for grownup drivers wanting to keep a wary eye on their juvenile - and occasionally unpredictable passengers!

Pete.