Heather Kay

Western Thunderer

Thanks Rob! I did try and recall your method, but had a brain fail.

I think your way would be better for longer coaches, too.

I think your way would be better for longer coaches, too.

Thanks Rob! I did try and recall your method, but had a brain fail.

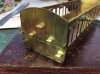

MRJ 28 is your friend here... the text describes how to convert the later style of Dean panelling / windows, as per the Slater's kit, into the style shown in your most recent photos.... While fixing all the tiny bits, thoughts wandered into whether it might have been possible to kit bash a couple of Slater's Dean coaches to do all this laborious stuff for me!

Heather, I am not certain about the Great Western but on other railways the oil lamps were only put in the holders when needed. Circular low domed covers were provided for use when the lamps weren't in place and a circular ring was provided adjacent to the lamp hole to hold the covers when the lamps were in use. It is unlikely that the lamps would have been serviced or filled on the roof of carriages due to the danger and risk of fire. They would have been taken back to lamp rooms for refilling, wick trimming, chimney cleaning etc. The oil lamps would have been changed over when refilling was needed and wouldn't usually stay with the same carriage, although on a short branch line they probably would stay with the same stock and be serviced at one of the termini.Cheers Mike!

I'm pondering those pads I mentioned. It seems they are lamp plugs (function unclear), but I don't have any suitable parts in this collection of parts. That said, the S6 kit does have some castings - but they don't quite look like what I see in photos.

Now, before I contact the Broad Gauge Society stores to see if they can separately supply the parts packed in the S6, does anyone know of a supplier that can supply suitable bits?

Have you tried one of these?