Thanks Pete!

As I mentioned earlier in the thread, this build is already part way through. Because of this I am sort of restricted as far as choices are concerned, being somewhat stuck with what the client did. The finished model will look like a 4200, but whether it will be a dead accurate replica of 4250 is moot.

This morning I resolved the motion bracket issue. What you don't see here is the extensive off-list chats that go on between Graham and I. I punt questions here or via email, and sometimes within seconds of hitting "send" the phone will ring! Graham is, I am certain, gently guiding me away from my LNWR/LMS/BR(M) predilections to things Swindon.

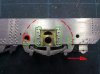

It turns out the bracket castings were often shimmed as the slide bars wore. As the cast brackets are slightly - half a millimetre each side - too wide, the answer was to solder in some thin shim material, and fettle to ensure the crosshead still moved smoothly.

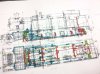

I found the easiest way to align the bracket with the structure above the running plate was to mount the frames to the superstructure with the cylinders in situ. A quick dab with the RSU held things together, and I made the joints firmer by taking everything off the loco again. A bit of tidying, and I was pleased with the result.

At this stage it rather looked like the etched bracket support plate across the frames might be superfluous. However, I had decided the cylinder block should be removable - it has to be so I can fit the front drivers again! - so a modicum of trimming things let the plate fit.

So, aside from the valve chest covers, I reckon the cylinders and slide bars are complete. I think the next move should be to motorise the chassis.

Pushing-along-the-test-track trials yesterday showed that even opening arches in the front frame extensions was not enough to prevent the truck derailing. A small amount of surgery has chamfered the frames behind the cylinders, which I hope will provide sufficient swing to get the model round a 5ft 6in curve. The issues of driving wheel sideplay is yet to be sorted out, so expect some fun and games!

. I think Pete still owns 5224.

. I think Pete still owns 5224.

.

. . I think Pete still owns 5224.

. I think Pete still owns 5224.

.

.

, just a couple more to go

, just a couple more to go  .

.