Spitfire2865

Western Thunderer

The motion is finished. And it is SO satisfying playing with it in the simulation. It will look perfect once I actually get around to building it.

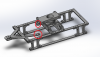

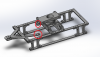

Ive also made a start on the engine truck.

Everything seems fairly straight forward aside from one specific part which I cant find reference to anywhere in my drawings besides the individual part drawings and an overall sideview which hides most of it.

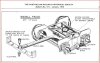

This photo views the right side and the mystery bits are highlighted. The forked part clearly bolts to the frame there due to the hole patterning, and the downward angled strap hangs forward and down according to the side view line drawing, however the center bolster mount has a hole that "almost" matches the lower strap's hole. (I account calculator rounding limit to that fraction of a millimeter misalignment)

Now my issue is in operation, the swing links will rock the frame in relation to that top bolster mount(which is mounted to the cylinder casting), thus changing the angle between the relevant holes.

Ive yet to find an assembly drawing that shows these parts, nor a part drawing of anything that could link them.

Odder still, I have yet to model one part of the Engine Truck, a brace that goes from the ends of the top frame to the center bolster. This would cross where these two holes should line up.

This isnt even considering how when the truck turns, the distance changes.

Has anyone ever seen an arrangement like this? Is this meant as some form of sprung self centering aid that Im just missing a drawing for?

Ive also made a start on the engine truck.

Everything seems fairly straight forward aside from one specific part which I cant find reference to anywhere in my drawings besides the individual part drawings and an overall sideview which hides most of it.

This photo views the right side and the mystery bits are highlighted. The forked part clearly bolts to the frame there due to the hole patterning, and the downward angled strap hangs forward and down according to the side view line drawing, however the center bolster mount has a hole that "almost" matches the lower strap's hole. (I account calculator rounding limit to that fraction of a millimeter misalignment)

Now my issue is in operation, the swing links will rock the frame in relation to that top bolster mount(which is mounted to the cylinder casting), thus changing the angle between the relevant holes.

Ive yet to find an assembly drawing that shows these parts, nor a part drawing of anything that could link them.

Odder still, I have yet to model one part of the Engine Truck, a brace that goes from the ends of the top frame to the center bolster. This would cross where these two holes should line up.

This isnt even considering how when the truck turns, the distance changes.

Has anyone ever seen an arrangement like this? Is this meant as some form of sprung self centering aid that Im just missing a drawing for?

.

.