GWR P7 (Southwark Bridge Models kit)

AJC

Western Thunderer

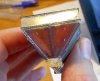

I've been in a soldering sort of a mood this week and so I've started working through something tiny but complex in the form of Southwark Bridge Models' GWR P7 hopper. Lots of really very small parts and a perhaps unnecessarily complicated mode of construction (compared to one of @jjnewitt's designs say), but all the bits fit so that's something. The really fun bit, the brakegear, is next...

Nice shot of the real thing at Evercreech Junction (the excuse for building one of these) here: GWR and Constituents | CH04986 - 'Herring' 20-ton ballast hopper No. W60274 at Evercreech Junction 24/10/59

I'll have to get one of Justin's Herring for comparative purposes.

Adam

Nice shot of the real thing at Evercreech Junction (the excuse for building one of these) here: GWR and Constituents | CH04986 - 'Herring' 20-ton ballast hopper No. W60274 at Evercreech Junction 24/10/59

I'll have to get one of Justin's Herring for comparative purposes.

Adam

Last edited:

.

.