mickoo

Western Thunderer

I'm sure I've posted some of this elsewhere but failed to find it so a new bespoke thread on this developing build I think is in order.

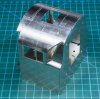

The cab has already been done and a test build completed, there are a few corrections to be implemented from lessons learnt on the 1:43.5 build but fundamentally it all form up and fits where it should fit and essentially good to go.

However, over the Xmas break whilst everyone was making jolly I skulked away to the man cave for the duration and worked up the casing etches which finally came back today.

There's a couple of design elements that might not make it into a production run but are sufficient for my own build in my collection, the primary one was splitting the casing in two, a front and rear section with a lap joint, the bulkheads have holes in for stringers which should produce a light but rigid and strong frame.

The idea on the joint is simply to get the sides through my rollers and I suspect most 7mm modelers rollers, at 13" long it's way bigger than most desk top rollers we have. The inner shell will have the sides formed in the rollers and then joined, the outer skin doesn't need rolling as it'll be tacked to the shell and will easily form the correct curvature.....he says!

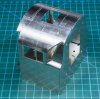

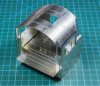

Inner shell and front platform.

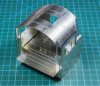

Outer etched skin, bulkheads and other periphials.

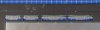

On paper the name plates looked perfect, but once etched the class name has over etched, I didn't expect that so that's one area that will need revising with beefier text.

The smaller text is just visible to the eye but will not stand out once painted, I think the main text also needs a bit more full fat coke to get just right.

More later.

MD

The cab has already been done and a test build completed, there are a few corrections to be implemented from lessons learnt on the 1:43.5 build but fundamentally it all form up and fits where it should fit and essentially good to go.

However, over the Xmas break whilst everyone was making jolly I skulked away to the man cave for the duration and worked up the casing etches which finally came back today.

There's a couple of design elements that might not make it into a production run but are sufficient for my own build in my collection, the primary one was splitting the casing in two, a front and rear section with a lap joint, the bulkheads have holes in for stringers which should produce a light but rigid and strong frame.

The idea on the joint is simply to get the sides through my rollers and I suspect most 7mm modelers rollers, at 13" long it's way bigger than most desk top rollers we have. The inner shell will have the sides formed in the rollers and then joined, the outer skin doesn't need rolling as it'll be tacked to the shell and will easily form the correct curvature.....he says!

Inner shell and front platform.

Outer etched skin, bulkheads and other periphials.

On paper the name plates looked perfect, but once etched the class name has over etched, I didn't expect that so that's one area that will need revising with beefier text.

The smaller text is just visible to the eye but will not stand out once painted, I think the main text also needs a bit more full fat coke to get just right.

More later.

MD