You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

mickoo

Western Thunderer

Steve,

I heard

I did reply, but just checked and seen it hasn't even acknowledged I'd replied or written anything, thank you anyway but I whizzed the shape up in Autocad, printed, stuck on some sheet nickel and cut around the dotted line.

Len,

That's not quite what I said

Roger,

I'm not impressed, it'd just been washed the penultimate time, a couple of bits to add for tomorrow and it would of been packed away, now it's an expensive bin filler; I know it's only a test build but it's the time lost that's the killer. I could try a new skin but on the skin etch are all the core bulkheads and if you've got that lot then you may as well get the other sheet etched as well.

It's repaired as good as can be in the time and I've lost some of the rivets in that corner to get the skin even looking sort of flat.

It'll survive until Sunday and then be blow torched apart to recover the 3.0 mm tubes for the MkII shell, the rest will go in the bin.

MD

I heard

I did reply, but just checked and seen it hasn't even acknowledged I'd replied or written anything, thank you anyway but I whizzed the shape up in Autocad, printed, stuck on some sheet nickel and cut around the dotted line.

Len,

That's not quite what I said

Roger,

I'm not impressed, it'd just been washed the penultimate time, a couple of bits to add for tomorrow and it would of been packed away, now it's an expensive bin filler; I know it's only a test build but it's the time lost that's the killer. I could try a new skin but on the skin etch are all the core bulkheads and if you've got that lot then you may as well get the other sheet etched as well.

It's repaired as good as can be in the time and I've lost some of the rivets in that corner to get the skin even looking sort of flat.

It'll survive until Sunday and then be blow torched apart to recover the 3.0 mm tubes for the MkII shell, the rest will go in the bin.

MD

Simon

Flying Squad

Ouch!

Now that's where my Aster has an advantage, it would have bounced better and probably dented the floor

Seriously, that's a blow. Can you not hammer it out and fill and fil etc? Of course the great irony is that the prototype casing was invariably anything but rippled, dented or otherwise imperfect, although I don't intend to replicate such a finish on mine either!

Please keep up the good work, you are likely to get me starting Watersmeet, which would be a very good thing

Simon

Now that's where my Aster has an advantage, it would have bounced better and probably dented the floor

Seriously, that's a blow. Can you not hammer it out and fill and fil etc? Of course the great irony is that the prototype casing was invariably anything but rippled, dented or otherwise imperfect, although I don't intend to replicate such a finish on mine either!

Please keep up the good work, you are likely to get me starting Watersmeet, which would be a very good thing

Simon

mickoo

Western Thunderer

Simon,

I've split the skin from the core but the special slots designed to hold the skin neat and close to the core worked so well it took a blow torch to get the two apart, which resulted in the the skin buckling from the heat so it hasn't gone back perfectly flat.

The inner core straightened reasonably well, but that's the bit you don't see so isn't visually important; but the skin has creases in that just cannot be removed. Ironically if it were in brass, which is more malleable, then it probably would of smoothed out much better; NS once creased is basically scrap.

It's cleaned up as best possible and I'll show some photos later once the smokebox top fences and sand box fillers are fitted, but it's lost a fair few etched rivets back there and the idea of this build was for a demo model eventually, can't put this on any table in reality, as a show and tell, yes; as a final product display model....no.

There was always going to be a MkII, in fact, during this build the tweaks needed have already been done, so a MkII etch is already to send for the current parts, all I needed / still need to do are fill the outside of the spare sheet with other nick nacks for the casing.

You're right, the real engines were pretty battered but as often mentioned, it's just not good cricket replicating that in model form

On a positive note, the whole exercise has shown that it is perfectly feasible and practical to design a kit in Gauge 1 using Gauge O techniques and build practices and I do much prefer working in the larger scale if I'm honest

MD

I've split the skin from the core but the special slots designed to hold the skin neat and close to the core worked so well it took a blow torch to get the two apart, which resulted in the the skin buckling from the heat so it hasn't gone back perfectly flat.

The inner core straightened reasonably well, but that's the bit you don't see so isn't visually important; but the skin has creases in that just cannot be removed. Ironically if it were in brass, which is more malleable, then it probably would of smoothed out much better; NS once creased is basically scrap.

It's cleaned up as best possible and I'll show some photos later once the smokebox top fences and sand box fillers are fitted, but it's lost a fair few etched rivets back there and the idea of this build was for a demo model eventually, can't put this on any table in reality, as a show and tell, yes; as a final product display model....no.

There was always going to be a MkII, in fact, during this build the tweaks needed have already been done, so a MkII etch is already to send for the current parts, all I needed / still need to do are fill the outside of the spare sheet with other nick nacks for the casing.

You're right, the real engines were pretty battered but as often mentioned, it's just not good cricket replicating that in model form

On a positive note, the whole exercise has shown that it is perfectly feasible and practical to design a kit in Gauge 1 using Gauge O techniques and build practices and I do much prefer working in the larger scale if I'm honest

MD

mickoo

Western Thunderer

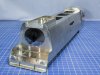

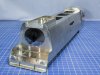

As the late great Freddy Mercury sang 'The Show must go on' and so it does with the 1:BLP (Bulleid Light Pacific)

Have repaired the bent bit as best possible the rest of the test etches were fitted and very late last night a quick paint job on the name plates ready for todays show, sadly no aircraft blue so opted for late BR red and black plates, it just adds a little colour to those oh so big flanks.

RH ¾ 'Spitfire'

LH ¾ 'Fighter Command'

The damage isn't really visible but once you pick it up and turn it the light catches it badly.

Front view

The depressed chimney well ribs worked out well and after a little cut and paste with some paper a basic cone chimney was cobbled up and test fitted. at the front end the frame extensions were tested and fitted and the two small lower wings added and wrapped around the front platform.

Side view

As most people said today,"it doesn't look that big on the forum" and it was nice to have something people can touch and pick up, as any trader will know, letting the public pick anything up is a huge risk but this being a damaged test build had no such risks.

It did generate a lot of interest, despite being a Gauge O show, enough interest to move to the next step and carry on researching and developing it.

MD

Have repaired the bent bit as best possible the rest of the test etches were fitted and very late last night a quick paint job on the name plates ready for todays show, sadly no aircraft blue so opted for late BR red and black plates, it just adds a little colour to those oh so big flanks.

RH ¾ 'Spitfire'

LH ¾ 'Fighter Command'

The damage isn't really visible but once you pick it up and turn it the light catches it badly.

Front view

The depressed chimney well ribs worked out well and after a little cut and paste with some paper a basic cone chimney was cobbled up and test fitted. at the front end the frame extensions were tested and fitted and the two small lower wings added and wrapped around the front platform.

Side view

As most people said today,"it doesn't look that big on the forum" and it was nice to have something people can touch and pick up, as any trader will know, letting the public pick anything up is a huge risk but this being a damaged test build had no such risks.

It did generate a lot of interest, despite being a Gauge O show, enough interest to move to the next step and carry on researching and developing it.

MD

Mike W

Western Thunderer

Well, doesn't that just show that the model isn't to today's standards. No crumple zones with excessively expensive replacement sections.

Handled this on Saturday (thanks) and never having handled a Finney BLP before I was really impressed by the strength - particularly torsional. Crisp detail, lovely build quality and really, really solid. I hope it is a commercial success for you - its a brave effort and deserves to succeed.

Mike

Handled this on Saturday (thanks) and never having handled a Finney BLP before I was really impressed by the strength - particularly torsional. Crisp detail, lovely build quality and really, really solid. I hope it is a commercial success for you - its a brave effort and deserves to succeed.

Mike

InvernessTMD

Western Thunderer

Mick, with regards to the top of the casing, my Judith Edge Hunslet had rows of half etched lines where the bonnet had to be curved, and using a basic set up they bent over really nicely and evenly... only works if the curve has to be straight of course!

mickoo

Western Thunderer

Yes, that is one option, but only works on full thickness etch.Mick, with regards to the top of the casing, my Judith Edge Hunslet had rows of half etched lines where the bonnet had to be curved, and using a basic set up they bent over really nicely and evenly... only works if the curve has to be straight of course!

The plan is to have all the bolts and rivets half etch like the skin, saves you hours punching them out and you can etch them different sizes and replicate the bolt heads in places.

If you half etch the outer skin then you can't add bend lines on the inside, well you can, but you need a layered etch process which just adds another level of complexity to the design stage.

The idea has potential merit because it would be possible to make the roof core from full etch (like the main casing) over which you lay the half etch skin, the skin taking the form of the core below.

MD

mickoo

Western Thunderer

Thanks, it's still a bit HMS Dreadnought technologyWell, doesn't that just show that the model isn't to today's standards. No crumple zones with excessively expensive replacement sections.

Handled this on Saturday (thanks) and never having handled a Finney BLP before I was really impressed by the strength - particularly torsional. Crisp detail, lovely build quality and really, really solid. I hope it is a commercial success for you - its a brave effort and deserves to succeed.

Mike

but is certainly robust.

but is certainly robust.At the moment the driving force isn't commercial, it's an engine in a scale that a handful of people want (myself included) and this is a demo / trial build to see if it's even practicable, which so far it has shown to be.

Alongside this I'd love an Gresley A3, Peppercorn A1 and Britannia

Anyway, back in the 'real' world, nice chatting to you yesterday, and everyone else as well

MD