You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Book Books and a library

- Thread starter Martin Shaw

- Start date

Martin Shaw

Western Thunderer

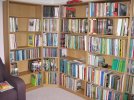

I find it difficult to believe it's a fortnight since my original post, who knew so much interest could be generated by Swedish bookshelves. As it is my books are now back on the shelves although not ncessarily where I want them, (shades of Morecambe and Wise he said giving his age away).

It's all looking fairly smart. I was having a tele conversation with that nice Mr Castens this morning, more books on the way almost inevitably and we were discussing this thread and the interesting things that have come out of it. Weight is without doubt an issue,

this shelfs contents weigh around 45Kgs and there is already a noticeable sag. One suggestion from Richard utilising ali angle as an edge support struck a chord and I though an experiment worthwhile. I hived myself off to the darkest recesses of Ibrox and purchased a metre of 3/4" square by 1/8" angle for the sum of £5. This was measured, marked, cut, and drilled to produce a reinforcing angle bolted to the rear of a shelf. The front would be better however the loss of shelf height would perhaps be a problem whereas at the rear there is more than adequate space. It can't be anything other than beneficial however I'll try it for a while before committing to doing the whole lot.

The bolts are all I could find, some better will be got.

It doesn't impose too much and I think some black paint would hide it even more, twenty of them is a bit of work though so no rush on my part. I would like any views as to whether this is thought a worthwhile mod.

Regards

Martin

It's all looking fairly smart. I was having a tele conversation with that nice Mr Castens this morning, more books on the way almost inevitably and we were discussing this thread and the interesting things that have come out of it. Weight is without doubt an issue,

this shelfs contents weigh around 45Kgs and there is already a noticeable sag. One suggestion from Richard utilising ali angle as an edge support struck a chord and I though an experiment worthwhile. I hived myself off to the darkest recesses of Ibrox and purchased a metre of 3/4" square by 1/8" angle for the sum of £5. This was measured, marked, cut, and drilled to produce a reinforcing angle bolted to the rear of a shelf. The front would be better however the loss of shelf height would perhaps be a problem whereas at the rear there is more than adequate space. It can't be anything other than beneficial however I'll try it for a while before committing to doing the whole lot.

The bolts are all I could find, some better will be got.

It doesn't impose too much and I think some black paint would hide it even more, twenty of them is a bit of work though so no rush on my part. I would like any views as to whether this is thought a worthwhile mod.

Regards

Martin

Last edited:

Rob R

Western Thunderer

Martn,

My 800mm Billy bookshelves have a small gap between the back of the shelf and the rear of the unit.

*edit* the hardboard panel has bowed out. Maybe trim the back of the shelf?

Could you not turn the angle the other way up so that the vertical leg goes up behind the shelf making it all but invisible from the front?

Or a larger section angle positioned as above to give it a bit more flex resistance?

I suspect that the front of the shelf will still bow over time but not as much.

Knowing what I know now I would have gone for 400mm units throughout, being in a slimmer box they would have been a lot easier to fit in the car....

Rob

My 800mm Billy bookshelves have a small gap between the back of the shelf and the rear of the unit.

*edit* the hardboard panel has bowed out. Maybe trim the back of the shelf?

Could you not turn the angle the other way up so that the vertical leg goes up behind the shelf making it all but invisible from the front?

Or a larger section angle positioned as above to give it a bit more flex resistance?

I suspect that the front of the shelf will still bow over time but not as much.

Knowing what I know now I would have gone for 400mm units throughout, being in a slimmer box they would have been a lot easier to fit in the car....

Rob

Martin Shaw

Western Thunderer

Thanks for your thoughts Rob, I have two concerns, firstly if the stiffening angle is uppermost on the shelf there is potential to seriously damage a book as it hits the angle/securing nuts and bolts. A few of my books are ether irreplaceable or cost significantly more than the whole bookcase and it's not a risk I want. As it is a countersunk recess should be no worse than as designed. Secondly I think the size of the angle could be larger in some cases but not all, a one size solution doesn't place limitations even if it's not quite as effective. This pragmatic approach is well and good. If I were to do it from scratch again I think custom built would have to be the way even if I don't even want to think about the cost.

I agree that all 400 wide units would be better but it would be an extra £120 which would be more than my add on is going to cost. As it is since the decor/carpeting is finished changing anything is a no go anyway and I'll have to live with the outcome. Bit like the governments energy policy.

Kind regards

Martin

I agree that all 400 wide units would be better but it would be an extra £120 which would be more than my add on is going to cost. As it is since the decor/carpeting is finished changing anything is a no go anyway and I'll have to live with the outcome. Bit like the governments energy policy.

Kind regards

Martin

Martin Shaw

Western Thunderer

Rob

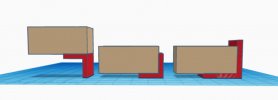

1 is my tryout which works but, both 2 and 3 are better but both involve modification to the shelves themselves, I have no clearance between the shelf and the rear panel. Trimming an 1/8" off the rear of several pieces of chipboard is I fear pushing my luck a bit. I think I might have the pragmatic answer given taking them all apart isn't going to happen, but thanks for the ideas which are stored if I'm ever here again.

Martin

1 is my tryout which works but, both 2 and 3 are better but both involve modification to the shelves themselves, I have no clearance between the shelf and the rear panel. Trimming an 1/8" off the rear of several pieces of chipboard is I fear pushing my luck a bit. I think I might have the pragmatic answer given taking them all apart isn't going to happen, but thanks for the ideas which are stored if I'm ever here again.

Martin

simond

Western Thunderer

I guess the stiffness of any add-on will critically depend on the vertical dimension of the vertical web, provided it is thoroughly and firmly attached to the shelf, of course. (mostly at the ends, the middle fixing probably doesn't add much if any stiffness)

I suspect that #1 at the rear, and #2 at the front would go a long way to stiffening the shelves without risking damage to the books, though #1 along both edges would be more effective, all other things being equal. If there is room to have a web facing down at the front, then a "TEE" would be best, with the leg horizontal and attached to the underside of the shelf, and the top vertical, effectively combining 1 & 2.

I'd avoid steel angle, it's heavy and much harder to work, and the thin stuff is probably not much use.

I suspect that #1 at the rear, and #2 at the front would go a long way to stiffening the shelves without risking damage to the books, though #1 along both edges would be more effective, all other things being equal. If there is room to have a web facing down at the front, then a "TEE" would be best, with the leg horizontal and attached to the underside of the shelf, and the top vertical, effectively combining 1 & 2.

I'd avoid steel angle, it's heavy and much harder to work, and the thin stuff is probably not much use.

Martin Shaw

Western Thunderer

I wonder, he thought out loud, whether it makes any difference in fixing an angle piece to the edge of a shelf, whether the vertical is above or below the horizontal element. To my simple mind the torsional benefit is the same irrespective, although I suppose it will take more force in compression and probably well beyond a load of books. Cleverer folk than I will I hope point out if my thinking is awry.

Martin

Martin

Richard Gawler

Western Thunderer

If the aluminium L seems a bit garish, you could try timber banister spindles. The 32 mm square ones in oak by Richard Burbage (sold in B&Q) would tone with the shelves. Ordinary wood glue like Resin W will create a really strong joint, just leave it clamped overnight. I used these spindles in some speaker stands, they can look very good.

Martin Shaw

Western Thunderer

Thanks Richard, I doubt I have 32mm clearance in all locations where strengthening may be required. I think a suitable shade of brownish paint will probably do. Having said all this at least two of the old bookcases came with us when we moved so they were at least 10 years old and whilst sagging somewhat didn't seem in imminent danger of collapse, perhaps the recent expenditure has pushed this up the conciousness scale. Nonetheless a further consideration.

Regards

Martin

Regards

Martin

Ian@StEnochs

Western Thunderer

The bottom shelf doesn't sag so my solution is a piece of 6mm ply, book width, in the middle of each shelf. Its enough to support the shelfs above and is virtually invisible.

Brian McKenzie

Western Thunderer

To prevent sagging of longer shelves, I fitted U shaped pieces of sheet metal in between (1.6mm zinc coated steel).

The legs project just shorter than the depth of the shelves, and are not noticeable in use. They also proved most excellent for keeping runs of magazines upright in tidy order, and beneficially, books don't need to be stacked so tightly to keep them properly upright.

For Martin's shorter length shelves, an L shaped divider (with the foot of the L across the back) might prove ideal.

-Brian M.

The legs project just shorter than the depth of the shelves, and are not noticeable in use. They also proved most excellent for keeping runs of magazines upright in tidy order, and beneficially, books don't need to be stacked so tightly to keep them properly upright.

For Martin's shorter length shelves, an L shaped divider (with the foot of the L across the back) might prove ideal.

-Brian M.

simond

Western Thunderer

I’ll not claim “cleverer”, but the issue is bending, not torsion.I wonder, he thought out loud, whether it makes any difference in fixing an angle piece to the edge of a shelf, whether the vertical is above or below the horizontal element. To my simple mind the torsional benefit is the same irrespective, although I suppose it will take more force in compression and probably well beyond a load of books. Cleverer folk than I will I hope point out if my thinking is awry.

Martin

Angle is about as stiff in torsion as flat bar of the same total width and thickness, which is generally counter-intuitive, but still the case!

The bending is resisted best by a deep section (think twanging a ruler over the desk edge, compared to bending it when it’s upright) and so fixing the angle to the shelf so the height of the flange is added to the thickness of the shelf will be the stiffest. The flange below, is in tension so won’t buckle. If you put the flange above, obviously it would be in the way, but the failure would eventually be the flange buckling as the shelf collapsed. Putting the flange in line with the shelf, like the middle diagram, will add the stiffness of the angle to that of the shelf, for negligible weight, and the shelf itself will tend to prevent buckling. This might be a worthwhile addition to the front of the shelves.

alternatively, an extruded aluminium tube say 15mm square, might be screwed below the shelf, if there’s space. That’ll be stiffer still.

if you go down the ally angle / tube route, there are lots of on-line metal resellers who have a better range and better prices than the DIY sheds.

Brian’s dividers are a very effective solution.

Richard Gawler

Western Thunderer

The bottom shelf doesn't sag so my solution is a piece of 6mm ply, book width, in the middle of each shelf. Its enough to support the shelfs above and is virtually invisible.

Martin, you can buy spare Billy shelves from Ikea. It might be possible to cut these into panels and use them like Ian's ply, but bring the veneered fronts out level with the fronts of the shelves something like this:

I have cut similar panels with a circular saw, score a line on the top side of the veneer to keep a neat line.

Martin Shaw

Western Thunderer

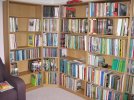

I'm grateful to all of you for the immensely helpful and varied suggestions, all have sufficient merit to implement but I think the easiest for me is the vertical ply divider which I can stain to a sort of match. It effectively turns them into 400 wide units which I should have considered initially, hey ho.

Kind regards

Martin

Kind regards

Martin

Chris Veitch

Western Thunderer

An interesting thread, having been privileged to have a tour of Martin's enviable library when we visited in January. I have a similar problem myself so it's good to see how other people have dealt with it. It's also good to see how many apparently "standard gauge" people have collection of many of the better NG books!

Simon

Flying Squad

First of all I'd like to thank Martin for getting me to send him quite a lot of nice heavy books to test his shelving.

(The consignment is being picked up today for delivery to you tomorrow Martin)

I am a great fan of "Billys" and the shop area here is really a Billy showroom, complete with fittings you can no longer get and the earlier 600 wide shelf units, which were less "saggy".

I have to say that I am greatly in favour of the "vertical divider method", which I have used extensively. Spare matching shelves are ideal, which I have used, but being parsimonious I have also used appropriately thick plywood and old veneered kitchen carcasses, all cut about as required.

You can also cut the uprights so that their faces are a bit recessed from the front of the shelf, which helps aesthetically I like to think.

Mind you, cutting them to the right length is a bit of a palaver, I found small pieces of mount board suitably wedged in afterwards to be a great help!!

Simon

(The consignment is being picked up today for delivery to you tomorrow Martin)

I am a great fan of "Billys" and the shop area here is really a Billy showroom, complete with fittings you can no longer get and the earlier 600 wide shelf units, which were less "saggy".

I have to say that I am greatly in favour of the "vertical divider method", which I have used extensively. Spare matching shelves are ideal, which I have used, but being parsimonious I have also used appropriately thick plywood and old veneered kitchen carcasses, all cut about as required.

You can also cut the uprights so that their faces are a bit recessed from the front of the shelf, which helps aesthetically I like to think.

Mind you, cutting them to the right length is a bit of a palaver, I found small pieces of mount board suitably wedged in afterwards to be a great help!!

Simon

Martin Shaw

Western Thunderer

OK I promise that this will be positively my last word on books. Thank you for your kind words Chris, the gauge of the rails has little bearing on my interest, it seems to vary between 9mm and 7' 0.25" according to mood.

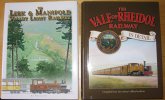

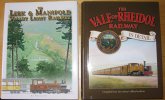

Two of my latest NG acquisitions, the L&M book was a limited edition published by the late Roy Link in 2005. I couldn't afford it at the time and it's taken since then to acquire a decent sh copy at a reasonable price, absolutely gorgeous. The Rheidol book was only published by the VoR themselves this year, it's beautifully designed by Steve Phillips who I know is highly rated by Simon, I would heartily agree with that assessment, an absolutely stunning piece of work. The binding isn't quite up to top qualiy, a creaking when opened suggests a glue process rather than sewing which is unforgivable at this price and a detriment to all the rest of high values in the production, unfortunately we measure far too much in this world by how little it costs, he grumpily mentioned. Thanks Simon for the heads up.

Martin

PS. I have subsequently been advised and much to my reassurance that the binding on the VoR book is sewn.

Two of my latest NG acquisitions, the L&M book was a limited edition published by the late Roy Link in 2005. I couldn't afford it at the time and it's taken since then to acquire a decent sh copy at a reasonable price, absolutely gorgeous. The Rheidol book was only published by the VoR themselves this year, it's beautifully designed by Steve Phillips who I know is highly rated by Simon, I would heartily agree with that assessment, an absolutely stunning piece of work. The binding isn't quite up to top qualiy, a creaking when opened suggests a glue process rather than sewing which is unforgivable at this price and a detriment to all the rest of high values in the production, unfortunately we measure far too much in this world by how little it costs, he grumpily mentioned. Thanks Simon for the heads up.

Martin

PS. I have subsequently been advised and much to my reassurance that the binding on the VoR book is sewn.

Last edited: