To complement Micks notes, less is more, the more solder you use, the more you'll end up cleaning.

I never solder outside if you I can solder inside and I almost always use a micro torch, I have to on the current model as the material is so thick not even the ERSA 80 touches it at 400°C

View attachment 118052

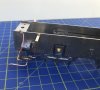

Front end of the Peppercorn A2, the only cleaning was the initial surface clean once all the cusp was removed, nice large piece of well worn emery cloth, and before the rivets were formed.

I modified the fold up valance jig to enable the whole front end to be built up nice and square.

The left hand valve chest cover has not been fitted but if you look at where it narrows you'll see a small sausage of solder (next to the slot at 90° in the footplate), that's all it needs, there will be another one behind the front wall and I'll stick one at the rear where it meets the frame top.

Even temperature is important and with a flame it is easy to get it too hot, the salmon pink tarnish over the middle cylinder is where the flame was left a little too long, but it'll buff out with a soft burnishing brush, like a fibre brush but much larger and softer.

Underneath is a different story.

View attachment 118053

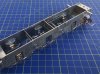

This is where all the work goes on, despite the solder presence the use of a flame makes sure it's nearly flat and is in effect no more than a tarnish/stain.

At left is the valance/footplate joint and you can see where the solder sausages were placed, their rough size and the gap between then that easily filled when the solder wicked along.

One little trick you can try is to use gravity, rather than solder flat I tilt the work a little so that the solder runs downhill, it makes it flow much faster and easier. If you get too much on the outside then place that joint uppermost and heat from below, the solder will then sag and seep through the joint and go to the inside, leaving virtually nothing on the outside.

Some people use ready fluxed solder (we call it wet at work, as opposed to dry which has no flux), I tend to find that the flux used in these turns a oily brown tar like puddle of

, once it does that solder will not run through it and just puddles in the middle.

Like Mick, I use dry solder (145°C) and safety flux applied with a small paint brush, I also clean the model regularly, sometimes with soapy water, (however, living in a hard water area that tends to leave water stains) but most of the time I just squirt LimeLite on it and then wash it off with very hot water.

As Mick notes and I'll vouch for this, the joint preparation is crucial, the better the joint the easier the solder flows, remove the cusp on all parts that touch and need to be soldered.

Hope that helps.

), and I can’t help but wonder at that nice, neat seam of solder that featured in several pictures of the tender-top in your thread of the 24th January.

), and I can’t help but wonder at that nice, neat seam of solder that featured in several pictures of the tender-top in your thread of the 24th January.

, once it does that solder will not run through it and just puddles in the middle.

, once it does that solder will not run through it and just puddles in the middle.