adrian

Flying Squad

As a small break from the loco building I decided to switch to building a MMP Glass Truck. For the simple reason it was advertised as a ScaleSeven kit so I was curious to see what you got. Although that said I haven't got a finescale kit available so I wouldn't really know what the difference was.

The kit certainly seems fully packed, aside from the two large sheets of etchings there were all the bits for the sprung W-irons, a bag of good quality castings with little or no flash on, plenty of strip wood of various sections to make the glass carrying cases, and even a length of thread for the lashing rope. Just over 2 pages of closely typed instructions and 5 pages of drawings.

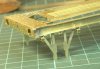

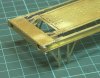

I find there's something therapeutic about cutting out etchings and punching lots of half etched rivets, and there are a lot of them! Starting with the main wagon bed, the ends are folded over for the buffer beams. and the solebars need folding and soldering to the main bed.

Soldering the folded solebars to the main bed was actually quite tricky, there is a small half etch recess for it to sit in but the strip on the main bed being so thin was prone to buckling slightly. Still just taking it slow and steady ended up with a straight and square main bed.

You may have noticed I've left a large chunk of etching in the middle. This should be cut out for the drop well to fit. However that would leave some narrow strips in the middle and given my clumsy nature felt sure I would bend them. So I'll cut the centre bit out when I'm ready to fit the well tanks.

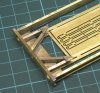

There was more riveting to be done and a few end plates to solder in.

This being the top side.

Even the plates underneath are rivetted.

Finally for now the W-irons are soldered in.

Next stage is making up all the brackets and leaf springs.

The kit certainly seems fully packed, aside from the two large sheets of etchings there were all the bits for the sprung W-irons, a bag of good quality castings with little or no flash on, plenty of strip wood of various sections to make the glass carrying cases, and even a length of thread for the lashing rope. Just over 2 pages of closely typed instructions and 5 pages of drawings.

I find there's something therapeutic about cutting out etchings and punching lots of half etched rivets, and there are a lot of them! Starting with the main wagon bed, the ends are folded over for the buffer beams. and the solebars need folding and soldering to the main bed.

Soldering the folded solebars to the main bed was actually quite tricky, there is a small half etch recess for it to sit in but the strip on the main bed being so thin was prone to buckling slightly. Still just taking it slow and steady ended up with a straight and square main bed.

You may have noticed I've left a large chunk of etching in the middle. This should be cut out for the drop well to fit. However that would leave some narrow strips in the middle and given my clumsy nature felt sure I would bend them. So I'll cut the centre bit out when I'm ready to fit the well tanks.

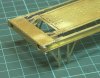

There was more riveting to be done and a few end plates to solder in.

This being the top side.

Even the plates underneath are rivetted.

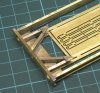

Finally for now the W-irons are soldered in.

Next stage is making up all the brackets and leaf springs.

Although tooooo many little bits to solder for my skills.

Although tooooo many little bits to solder for my skills.