michael mott

Western Thunderer

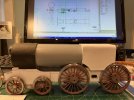

After doing a test assembly of equalization beam with the spring, it’s apparent that the way I have interpreted the beam will not work.

This caused a bit of a rethink as how to make the beams stepped. The beams are 1” thick and the printable card stock is.008” thick so 4 laminations =.032 basically 1 “. I decided to try to form the shape by making a small press using layers of styrene and then using a diluted carpenters glue 50/50 with water. I coated the two inner layers both sides with the glue and the outer layers only on the insides quickly sandwiched the stack between the forms.

Let it set up for another 15 minutes before removing it from the press (vice)

First test confirmed the principle. Next to use a print of the beam registered so that it will facilitate cutting it out once the glue has fully dried.

Michael

This caused a bit of a rethink as how to make the beams stepped. The beams are 1” thick and the printable card stock is.008” thick so 4 laminations =.032 basically 1 “. I decided to try to form the shape by making a small press using layers of styrene and then using a diluted carpenters glue 50/50 with water. I coated the two inner layers both sides with the glue and the outer layers only on the insides quickly sandwiched the stack between the forms.

Let it set up for another 15 minutes before removing it from the press (vice)

First test confirmed the principle. Next to use a print of the beam registered so that it will facilitate cutting it out once the glue has fully dried.

Michael