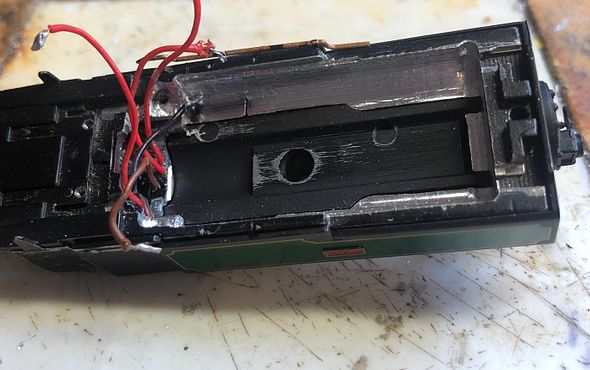

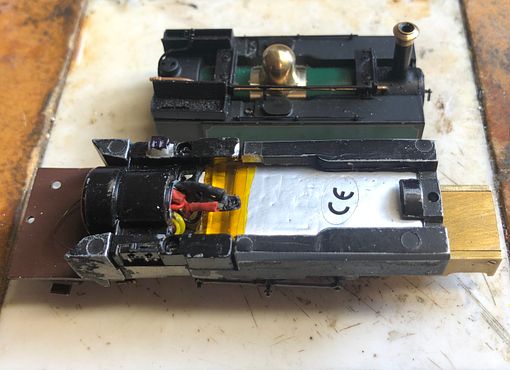

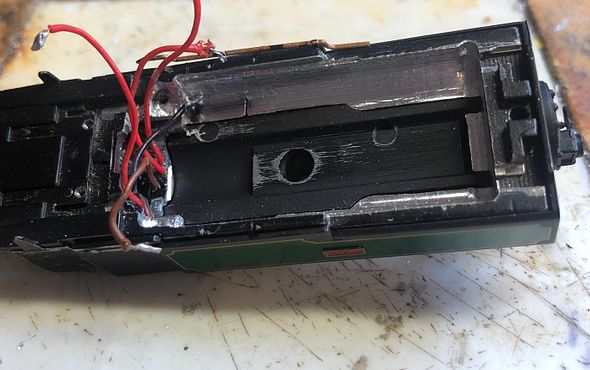

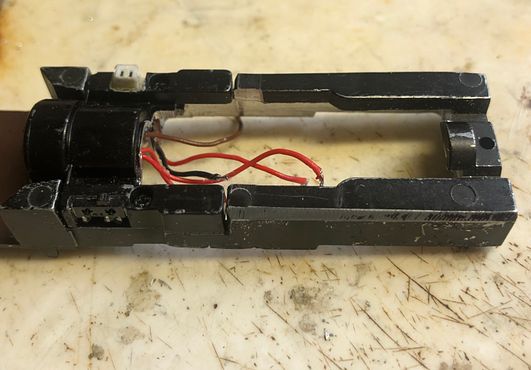

I wasn’t convinced that the 100 mAh battery on Yeo would give sufficient endurance on an exhibition layout. Running light engine, in thin air, it would turn over for about 90 minutes continuously. I have therefore sourced a 500 mAh battery. The only problem is that it is 40 x 20 x 6 mm. With some careful milling, there would be clearance in the tanks to accommodate this large slab.

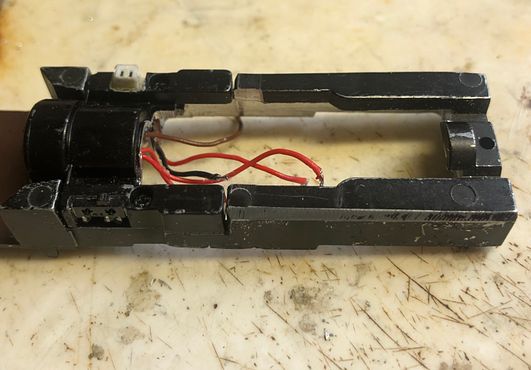

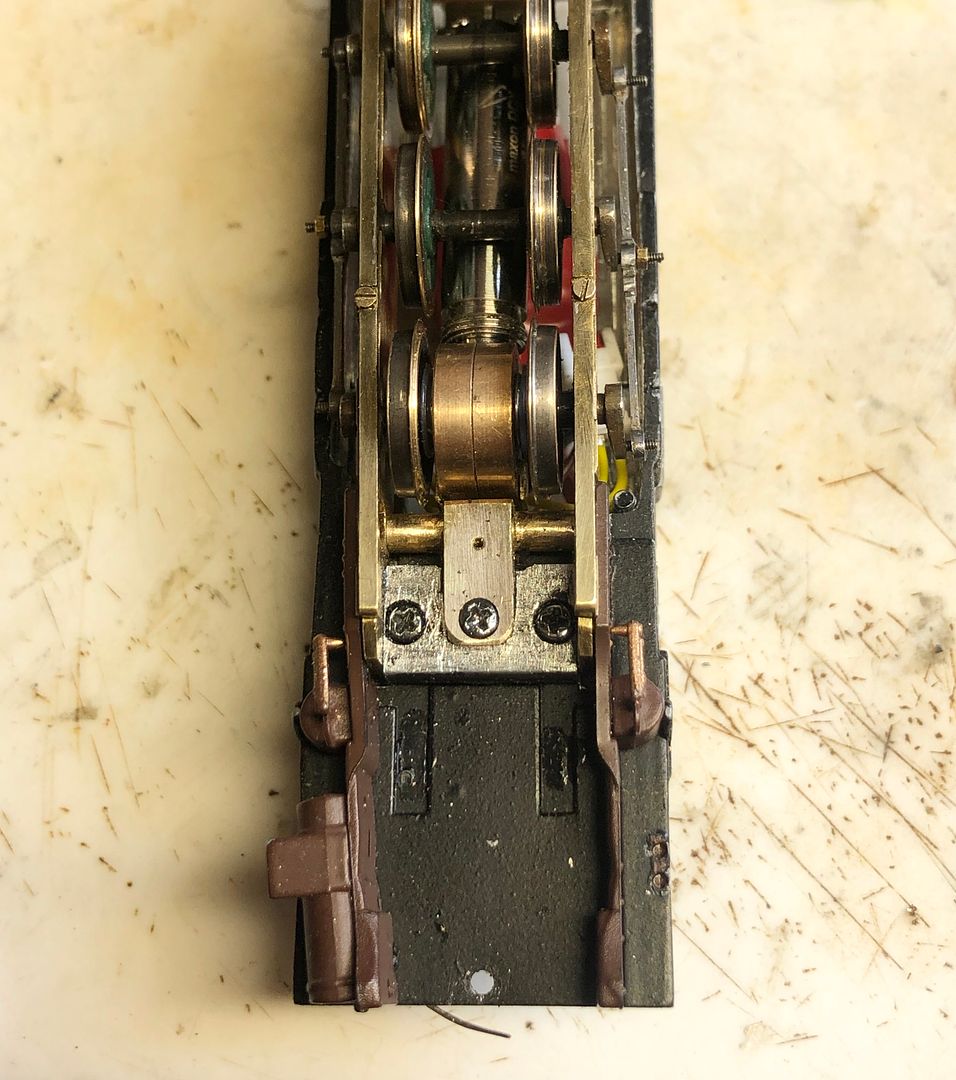

This would require the receiver and aerial to move rearwards into the space previously occupied by the small battery. I then had a light bulb moment (well LED actually) to use the little indicator light on the Rx to simulate a firebox glow. Before that little frippery, I spent a long time carefully removing a large amount of metal from the tanks. This was approached from underneath, maintaining the top for rigidity; the casting would otherwise be very fragile.

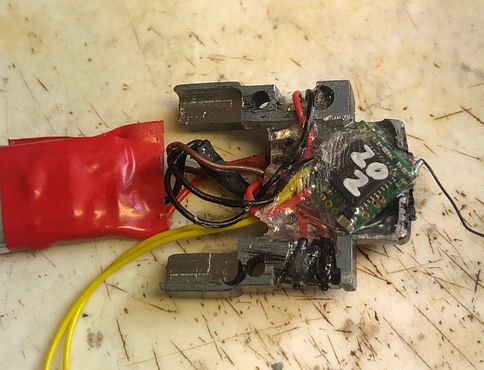

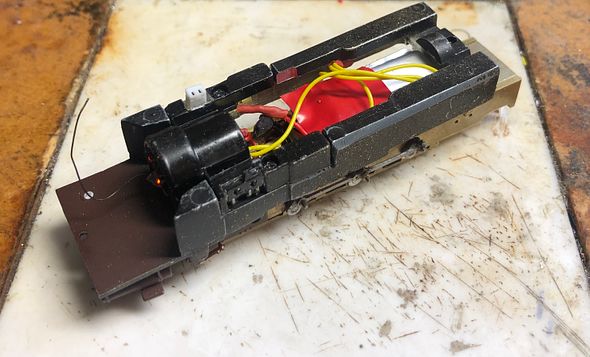

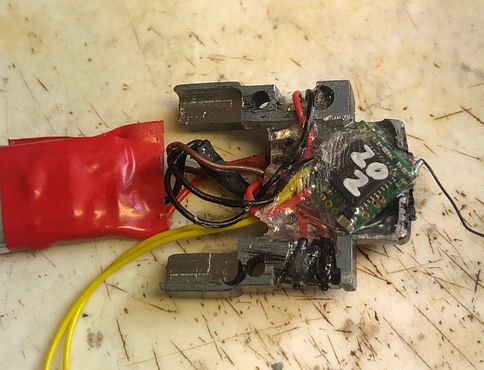

The Medusa’s head of wires would be tamed with the new Rx arrangements.

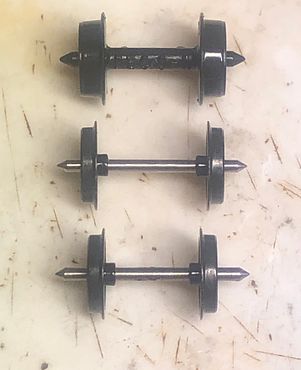

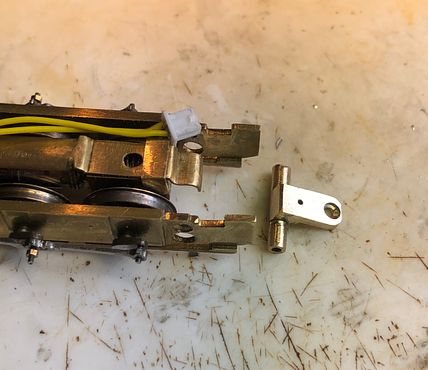

I don’t think the loss of weight will be significant because there will be a substantial brass block at the front as a frame spacer and mounting for the pony pivot - the original went in swarf up the hoover.

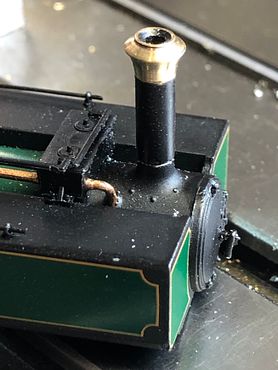

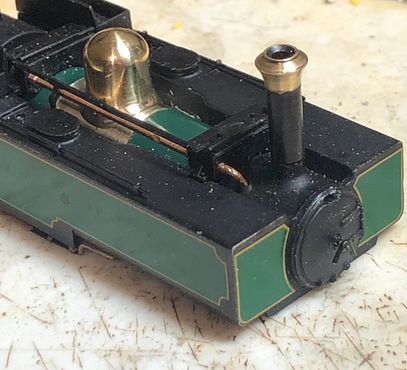

Turning to the receiver, this required space to turn it through 45 degrees so the the little LED On the corner could slightly protrude from the firebox doors which, along with other bits, were opened up with a TC bur in a lab hand-piece. The whole assembly was then glued into place with lashings of 5 minute epoxy resin - it’s important to sign your work with a thumb print, BTW (I have subsequently re-coated the Rx with Araldite, so the fingerprint has gone)

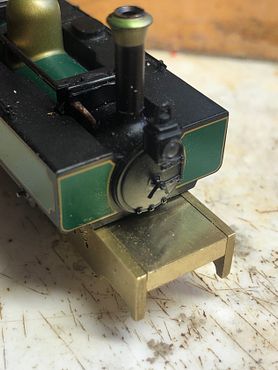

I roughly reassembled the bodywork to give this end result:

The fireman is very lazy to leave the firebox doors open, but it does look quite jolly. The light is actually quite important to see because it lets you know the status of the Rx. The aerial will double up as a rather long slack pipe.

Quite a pleasing days work. All I need to do now is wait for the new battery to arrive from over the seas and far away.

Tim