Since Christmas I just haven't felt the need to scratch my modelling itch.

I have done some more work to a Hall that I built over 12 years ago, but never added brakes or G hangers to it. The brakes are done. Little bit of CAD work and and little bit of 3D magic from Mr Newitt and hey presto. Perhaps I shall do this for the G hangers, I really haven't decided.

A few days ago I received a text from a friend of mine, Fred Lewis. Fred is well known builder of O gauge and a class act. Anyway, he had, had some P4 items that he thought that I'd be interested in. So yesterday evening we met. It's the first time that I've been to my club in probably 3 years. Certainly the first time since lock down 2 years ago.

Fred had with him a collection that he had bought from a fellow modeler and mutual friend, after his passing and with the blessing of the immediate family.

Tony Thorne (to most he was known as Tall Tony) and I used to meet most Thursday evenings in his spare bedroom to natter, model, smoke some fags and drink tea. After many years we drifted apart, for one reason or another, mostly the demands of work and family. So when Fred brought the enormous box of bits...imagine a tea chest and you won't be far out...

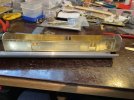

On opening the box, memories of completed work by Tony and myself, flooded back. 2, 9f chassis, a completed 56xx chassis, a pannier chassis all completed and running. Plus more spares than you can throw a stick at. As far as I can remember Tony ever completed one engine. An Avonside B3. This was a CSP kit. Tony was a very accomplished modeler that kept his light, well hidden. His passion for railways was all encompassing. BR, LNER, GWR and LMS all had a place in Tony's church.

So, what is this ramble about? The missing of a friend who'd passed, the past haunting the present. Or is it something else...all I know is that I'm grateful to my friend for the time we had together, for time that he helped me complete countless engines of mine, usually at the expense of completing his own work. It was a very odd feeling trawling through my friends possessions. But it showed me how much he loved his hobby. It showed a man with a burning passion not just for modeling but for the things that he modeled.

Looking back through Tony's collection has been a very sobering experience. Thanks to Fred for allowing me to reminisce.

Yes, I did come away with some treasures from Tony. I hope in the months to come to do them justice, just as Tony would have.

Stay safe

Mike

. I love the way my wife shares ALL of lifes glories. The contractor in me says, no work, no pay. The modeler inside me says "PARTY TIME". Feels just like a very heavy cold and I hope it stays that way.

. I love the way my wife shares ALL of lifes glories. The contractor in me says, no work, no pay. The modeler inside me says "PARTY TIME". Feels just like a very heavy cold and I hope it stays that way.