You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm MMP LMS 13 ton Mineral Wagon

- Thread starter farnetti

- Start date

Steve Cook

Flying Squad

Two months working out there. First three weeks alone....that's when I'm likely to do stuff, before wife gets there and has ideas about what we "ought to do"......

Taking those two and a Tower/DJH "Warship"....time will tell which, if any, gets done.

Cool, photos and a workbench thread then please

farnetti

Western Thunderer

Two months working out there. First three weeks alone....that's when I'm likely to do stuff, before wife gets there and has ideas about what we "ought to do"......

Taking those two and a Tower/DJH "Warship"....time will tell which, if any, gets done.

Goodness Alcazar, if I was going for that long I just know I would forget a vital tool or 5, maybe the kit as well.

Ken

farnetti

Western Thunderer

This really is a nice build

John

Thanks John, much appreciated although I have to say I could have done it better. I look forward to your posts and seeing again.

Ken

farnetti

Western Thunderer

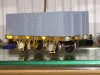

The end is in sight. Here you can see nearly all of the brake gear bits put together for ready for final fitting - brake shoes each made of 6 laminations with hangers, brake linkage brackets on tube to go through the V hangers together with washers, split pins and nuts, safety loops, brake levers and lever guides. The piece of wire at the bottom is to form further safety loops that go through the innermost holes on the linkage arms, I never even knew such things existed.

I will probably have to take the side door bangers off on one side to get the cross shaft through.

Have any of you any ideas as to how I can fit the chain to the lever brackets and pins? Twisting the last link and then reforming it like on 3 link couplings isn't an option, the chain is too fine.

The final pieces will be the 4 fabricated hooks on the buffer beams for sheeting ropes.

Because of all the fine detail I am nervous about giving the completed chassis a good scrub as I did the body. I notice some of you use an ultrasonic cleaner, do they affect the plastic wheel centres, superglue, araldite etc.

Ken

I will probably have to take the side door bangers off on one side to get the cross shaft through.

Have any of you any ideas as to how I can fit the chain to the lever brackets and pins? Twisting the last link and then reforming it like on 3 link couplings isn't an option, the chain is too fine.

The final pieces will be the 4 fabricated hooks on the buffer beams for sheeting ropes.

Because of all the fine detail I am nervous about giving the completed chassis a good scrub as I did the body. I notice some of you use an ultrasonic cleaner, do they affect the plastic wheel centres, superglue, araldite etc.

Ken

Rob Pulham

Western Thunderer

Have any of you any ideas as to how I can fit the chain to the lever brackets and pins? Twisting the last link and then reforming it like on 3 link couplings isn't an option, the chain is too fine.

Hi Ken,

That's what I did with my MMP Glass wagon, you will be surprised as it is possible

.

.Rob Pulham

Western Thunderer

Thanks Rob, I'll give it a go but I couldn't make out the join in the link, must need stronger glasses, presumably the twist made with fine tweezers.

Ken

Hi Ken,

I must admit that I used two pairs of fine nosed pliers - I don't really get on with using tweezers in that way - despite trying many times, the item usually ends up flying of into space never to be seen again

Perhaps it's my tweezers.

Perhaps it's my tweezers.Heather Kay

Western Thunderer

Perhaps it's my tweezers.

It really isn't. I can certainly sympathise.

farnetti

Western Thunderer

Sorted out the chain thingy thing and added the brake shoes with the hangers.

The cross shaft is not necessary as the brakes could not have worked otherwise. Is that why Morton brakes were introduced?

Final hurdle is the brake linkage. I know the arms from the V hangers to the shoes are not in a straight line but in my test fit they seem to be wildly obtuse.

Here's the latest piccies, sorry added the 2nd one twice.

View attachment 33295View attachment 33295

View attachment 33295View attachment 33295

The cross shaft is not necessary as the brakes could not have worked otherwise. Is that why Morton brakes were introduced?

Final hurdle is the brake linkage. I know the arms from the V hangers to the shoes are not in a straight line but in my test fit they seem to be wildly obtuse.

Here's the latest piccies, sorry added the 2nd one twice.

View attachment 33295View attachment 33295

View attachment 33295View attachment 33295Then deleted bothView attachment 33296

The instructions do not mention a complete crosshaft - ony the two short crosshafts that you have actually fitted - otherwise the bottom discharge doors could not work. That is the reason that the LMS Mineral wagons [not to mention so many others] had independent brakes.

See the Drawing in LMS Wagon Drawings Vol. 1 - the brake pull rods come out a quite a steep angle towards the linkage brackets inboard of the V hangers.

DJP

farnetti

Western Thunderer

The instructions do not mention a complete crosshaft - ony the two short crosshafts that you have actually fitted - otherwise the bottom discharge doors could not work. That is the reason that the LMS Mineral wagons [not to mention so many others] had independent brakes.

See the Drawing in LMS Wagon Drawings Vol. 1 - the brake pull rods come out a quite a steep angle towards the linkage brackets inboard of the V hangers.

DJP

I'm used to building much older wagons with brakes on one side only, hence my misunderstanding about the cross shaft. It hadn't been fixed so easy to remedy.

If the brake linkage units are hard up against the rear of the inner V hanger (which is implied by the 1.5mm protrusion mentioned in the instructions) the brake pull rods are at an angle of 8 degrees to the solebar which seems excessive. This also leaves no space for the upper, outer brake pull rods to pass between the brake linkage units and the inner V hanger.

I'm thinking that the brake linkage units should be further inboard to allow for this space and which would then also reduce the angle of the pull rods.

Ken

I'm used to building much older wagons with brakes on one side only, hence my misunderstanding about the cross shaft. It hadn't been fixed so easy to remedy.

If the brake linkage units are hard up against the rear of the inner V hanger (which is implied by the 1.5mm protrusion mentioned in the instructions) the brake pull rods are at an angle of 8 degrees to the solebar which seems excessive. This also leaves no space for the upper, outer brake pull rods to pass between the brake linkage units and the inner V hanger.

I'm thinking that the brake linkage units should be further inboard to allow for this space and which would then also reduce the angle of the pull rods.

Ken

Ken the inner pull rods + x4 thickness of the linkage unit [parts 44] = exactly 1.5mm which is what we suggest. As I say, the angle of the rods is pretty steep on the drawing but if you think it is still too much, it is a simple matter to inset the whole assembly by say, .5mm or so - or even a little more. I wouldn't cut any wire to final length on any of these assemblies until you have adjusted things to be how you want them.

Regards,

DJP

daifly

Western Thunderer

Ken (and DJP)

I'm really enjoying this build. It is so helpful to have the (kit) designer's input too. I've been so impressed with the obvious quality and design of the kit that I had a rush of blood to the head (and wallet) and bought one of these, along with an LMS 16T steel mineral, from MMP last week. It will be a while until I tackle them because of other projects and commitments but they will be something to savour, methinks.

Cheers

Dave

(and, yes, there will be photos at the appropriate time!)

I'm really enjoying this build. It is so helpful to have the (kit) designer's input too. I've been so impressed with the obvious quality and design of the kit that I had a rush of blood to the head (and wallet) and bought one of these, along with an LMS 16T steel mineral, from MMP last week. It will be a while until I tackle them because of other projects and commitments but they will be something to savour, methinks.

Cheers

Dave

(and, yes, there will be photos at the appropriate time!)

farnetti

Western Thunderer

Ken the inner pull rods + x4 thickness of the linkage unit [parts 44] = exactly 1.5mm which is what we suggest. As I say, the angle of the rods is pretty steep on the drawing but if you think it is still too much, it is a simple matter to inset the whole assembly by say, .5mm or so - or even a little more. I wouldn't cut any wire to final length on any of these assemblies until you have adjusted things to be how you want them.

Regards,

DJP

David,

Many thanks for your input and will probably do as you suggest. Have deliberately left/tube options open for this solution.

Ken