Ian Smith

Western Thunderer

It seems a very long time since I did any work on the layout, certainly anything documented. The truth is that I have done very little modelling over the last few months, but now Christmas is out of the way it's time to try to progress things a little.

So today I've made a start on the Up platform - the Down platform was made and temporarily bolted in place for the Tutbury show last year.

To start with a base of 0.040" plasticard was cut roughly to size then a set of dividers used to scribe a line some 8mm away from the nearest rail. Because the plastic sheet was not large enough to do the whole platform length from one sheet a join was needed part way along which was reinforced with a further patch of 0.040".

Because I had some from years ago, I decided to use the Peco platform edging strips for the platform wall and slab edging. However because they are clearly made for N Gauge "thick sleeper and code 55/80 rail" the wall section is far to tall. To rectify this problem, almost 2mm needed to be removed from the base of the wall. Once most of the amount had been removed by cutting with a knife, the remainder was carefully filed/scraped away while utilising a "locked-off" micrometer to check that all of the strips were the same depth and consistent along their lengths. To produce the ramp, the edging slabs on one strip were carefully removed with a hard-backed razor blade before the wall section was tapered over some 50mm, and the edging slabs reinstated. The individual strips were then cemented together to produce a complete platform edge from ramp to ramp.

The next stage was to attach the complete platform edge to the curved 0.040" base (the lines between the platforms are on a 10'0" radius bend). Before the walls could be attached though, some platform surface support pieces were cut from more 0.040" ensuring that the ends that will abut the inside of the walls were at 90 degrees to ensure that the platform walls would be vertical.

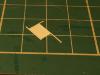

So that I could ensure that my platform edges will be equidistant from the rails along their whole length I've turned up a little roller gauge, the end of which extends out about 5mm from the inside face of the rail nearest the platform. This distance might be a little bit too much but a check on the Buffalo that I'm building shows that I will need close to that if the fly cranks/coupling rods/crank pin washers are to clear the platform edges.

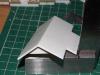

Finally, a couple of shots showing the progress at close of play today, the second illustrates quite nicely I think the gentle curve through the platforms.

Ian

So today I've made a start on the Up platform - the Down platform was made and temporarily bolted in place for the Tutbury show last year.

To start with a base of 0.040" plasticard was cut roughly to size then a set of dividers used to scribe a line some 8mm away from the nearest rail. Because the plastic sheet was not large enough to do the whole platform length from one sheet a join was needed part way along which was reinforced with a further patch of 0.040".

Because I had some from years ago, I decided to use the Peco platform edging strips for the platform wall and slab edging. However because they are clearly made for N Gauge "thick sleeper and code 55/80 rail" the wall section is far to tall. To rectify this problem, almost 2mm needed to be removed from the base of the wall. Once most of the amount had been removed by cutting with a knife, the remainder was carefully filed/scraped away while utilising a "locked-off" micrometer to check that all of the strips were the same depth and consistent along their lengths. To produce the ramp, the edging slabs on one strip were carefully removed with a hard-backed razor blade before the wall section was tapered over some 50mm, and the edging slabs reinstated. The individual strips were then cemented together to produce a complete platform edge from ramp to ramp.

The next stage was to attach the complete platform edge to the curved 0.040" base (the lines between the platforms are on a 10'0" radius bend). Before the walls could be attached though, some platform surface support pieces were cut from more 0.040" ensuring that the ends that will abut the inside of the walls were at 90 degrees to ensure that the platform walls would be vertical.

So that I could ensure that my platform edges will be equidistant from the rails along their whole length I've turned up a little roller gauge, the end of which extends out about 5mm from the inside face of the rail nearest the platform. This distance might be a little bit too much but a check on the Buffalo that I'm building shows that I will need close to that if the fly cranks/coupling rods/crank pin washers are to clear the platform edges.

Finally, a couple of shots showing the progress at close of play today, the second illustrates quite nicely I think the gentle curve through the platforms.

Ian

I also need to cut and fit the internal walls between the waiting room/ booking hall and office.

I also need to cut and fit the internal walls between the waiting room/ booking hall and office.