Heather Kay

Western Thunderer

I must be mad. As if I didn’t already have enough going on, I’m after starting another project!

Ages ago I made a snap purchase of three part-built Sparmac Gresley coaches. The price they were being offered at was very good, and I thought they’d make a nice project to complete and sell on to a new home. One of our WT inmates said he would like them, so the deal was done.

They slipped on to the back burner due to various things, but I did some research, got some excellent reference material together, and was inclined to purchase a set of Kemilway bogies for them. There followed a further hiatus while production difficulties at the Kemilway end held things up.

Eventually, the bogies appeared. I then proceeded to bungle wheelset orders from Slater's, and it was a further while before I had sufficient wheels for all three coaches. Then I discovered I was short of a pair of lightweight 8ft 6in bogie kits, so I got on to Peter at Kemilway. They duly arrived, had a cursory inspection and were safely stashed with the coaches.

Today, spring sunshine made me feel it was time to take a look at the kits properly. I selected the 8ft heavyweight as my starting point - only to discover the pack contained one 8ft and one 8ft 6in set of etches.

This project appears to be jinxed.

So, while I chase up the Big K again to sort out the muddle once and for all, I intend to make a start with one of the 8ft 6in bogie kits. Yes, I have checked the other to make sure it has the right bits in it, and the errant eight-footer wasn’t mixed somewhere. All is sweetness and light as far as the lightweights are concerned.

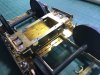

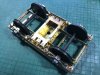

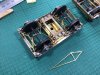

So, here’s what I’m presented with:

One pair of Kemilway/Pring BF5 8ft 6in bogie kits, not forgetting the 19 page construction manual. I may be a while. Send tea and cake.

Ages ago I made a snap purchase of three part-built Sparmac Gresley coaches. The price they were being offered at was very good, and I thought they’d make a nice project to complete and sell on to a new home. One of our WT inmates said he would like them, so the deal was done.

They slipped on to the back burner due to various things, but I did some research, got some excellent reference material together, and was inclined to purchase a set of Kemilway bogies for them. There followed a further hiatus while production difficulties at the Kemilway end held things up.

Eventually, the bogies appeared. I then proceeded to bungle wheelset orders from Slater's, and it was a further while before I had sufficient wheels for all three coaches. Then I discovered I was short of a pair of lightweight 8ft 6in bogie kits, so I got on to Peter at Kemilway. They duly arrived, had a cursory inspection and were safely stashed with the coaches.

Today, spring sunshine made me feel it was time to take a look at the kits properly. I selected the 8ft heavyweight as my starting point - only to discover the pack contained one 8ft and one 8ft 6in set of etches.

This project appears to be jinxed.

So, while I chase up the Big K again to sort out the muddle once and for all, I intend to make a start with one of the 8ft 6in bogie kits. Yes, I have checked the other to make sure it has the right bits in it, and the errant eight-footer wasn’t mixed somewhere. All is sweetness and light as far as the lightweights are concerned.

So, here’s what I’m presented with:

One pair of Kemilway/Pring BF5 8ft 6in bogie kits, not forgetting the 19 page construction manual. I may be a while. Send tea and cake.