In my never-ending quest to perfect the interiors of model coaches, I feel I have made a step forward.

The hardest thing for me has been to replicate the colour of the wooden veneers used in Mk1 coaches. In the past, I fear the interiors for coaches I have built were simply too dark (sorry Richard

) . Studying images, albeit of preserved vehicles, on Flickr shows the veneers to have a warm orangey glow, but it does depend on the timber used and the lighting conditions when photographed.

As examples, here's the view along a coach corridor:

East Anglian Railway Museum

East Anglian Railway Museum by

Deptford Draylons, on Flickr

And, while this user won't let me display the photo,

here's a view inside the passenger cabin of an open coach.

As you may recall, if you followed my other coach builds, I like to paint the wooden interiors and apply a dry-brushed grain effect over a base colour. I'm not going to try and match the mirrored pattern of the veneer, and to be honest most of the colour won't be visible at normal viewing distances. It's the overall effect I'm after, so I have to beat down my inner detail freak! All I am looking for is a more accurate rendition of the average interior colour.

The interiors of JLTRT coaches are made of various materials. The BSK is black styrene and pale resin, with a brass etched luggage cage. The TSO has brass floor, nice looking brass etched tables, black styrene and pale resin. Where I've detailed the inside of the ends, I've used white styrene. Being a lazy tyke, and not wanting to disturb the sides while the gloss varnish cured, I refused to prime everything and I spent a relaxing time brush-painting the various parts.

I set about mixing an orangey tan colour for a base coat, eventually settling on roughly 3 parts Humbrol Matt 63 and 1 part Matt 70, which I thinned down to a fairly watery consistency. The first coat didn't give sufficient coverage on the black styrene, although the effect on the resin toilet compartments was pretty close to what I wanted. Bear in mind I expected to overpaint grain effects, and finish with a satin varnish which generally darkens the colour and gives it more depth.

I let this paint dry overnight, and thought about it again this morning. I decided to mix the paint slightly thicker this time, and recoat all the surfaces that would be veneered on the real coach so everything was more or less the same base colour. It's all now drying, for at least 24 hours, before I consider the grain effect.

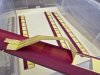

Here's the ends. At the back you can see I've painted one end, for the van end of the BSK, in a different colour (plain Matt 70), which is my mistake.

I'm trying to get the interior colours of the BSK correct, and from my reading of The Bible (Parkins' books on the Mk1s) the luggage area was painted in terracotta. Originally, it was meant to follow LMS practice with Venetian Red up to about 4ft, and buff or light tan above, with roof lining in white; this was later amended to Venetian Red up to the roof line, and subsequently it appears to be terracotta. Matt 70 is a sort of brick red, and I surmise once it's coated in satin varnish it'll darken down a notch or two, giving a reasonable terracotta. Study of photos, however, shows the end to be finished to match the roof, or at least buff if not white. Hence my mistake.

The photos in the early chapters of Parkins' book show lots of detail inside the brake end of the BSK/BFK. I know the inside of the guard's compartment was painted buff, so what about the short corridor from the passenger end to the luggage section? Knowing many black and white films are orthochromatic, meaning they render some colours - particularly reds - darker or lighter than they should be, and the corridor shot shows the fire equipment as a pale grey, I reasoned if reds are showing as light, then the corridor is probably finished in terracotta.

So, here's the first coat of interior colour on the BSK. You can see I've scribed the doors, as is my habit. The guard's compartment is currently still in the mucky brown the previous builder slapped all over!

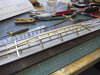

Here's the TSO, after first coat. The toilet compartments are left unpainted, because you can't see them.

Everything is now drying before I do the grain effect. I've also painted the seats for both coaches. As they're both second class, I believe the correct mocquette is dark red/maroon, so out with the brick red again! I plan to wash over with dilute black once they're dry to give a little modelling and shading. I'm not bothering with patterns. Life's too short! I think I'm already doing more than many builders try to do, present company excepted. The woodwork has been painted in the veneer base coat.

The TSO kit is a first for me, in that the floor is a brass etch. Likewise, the tables are a nice shiny etch, which will fold up into neat representations of the removable ones the real thing used. Looking forward to gluing all the plastic to the metal.

Mmm, shiny! Both floor and tables are now red oxide, drying in the paint shop.

While all this paint hardens, I shall set about underframes. More on that another time.

Worth every penny.

Worth every penny.

The van end has the fully-extended buffers with simple wire springing, while the other features the retracted version.

The van end has the fully-extended buffers with simple wire springing, while the other features the retracted version.

Still, it's whitemetal, and a dab or two of low-melt solder soon fixed things. Good as new. Now I could remove all the wheelsets and see what was what.

Still, it's whitemetal, and a dab or two of low-melt solder soon fixed things. Good as new. Now I could remove all the wheelsets and see what was what.