With the workbench cleared of green stuff I'm cracking on finishing the first of 3 part complete buildings - the ratio provender store.

Quote a lot of bits left on the sprues but on inspection most are surplus. Those that were needed have been primed and painted. Whilst they dry I've turned my attention to the roof.

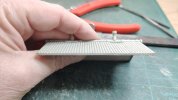

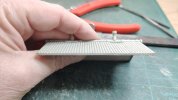

As provided the roof material is battleship armour plating thick, so the edge has been thinned down somewhat.

I wasn't going to bother but the building is front and center and it would bug me for years seeing the armour plating in photos.

Being made up of lots of sections the sides were quite flimsy so I've inserted some beams from spare sprue. Not quite prototypical as iirc they were a portal frame structure, but they will be very difficult to see.

I dug out some 10 Commandments wagon loads, which were bought over 15 years ago for our NCR exhibition layout Treneglos, took a saw to them and stuck some bits inside the store. Probably needed sacks but I didn't have any.

An experiment on the rear window. The frames are quite deep and, if glazed behind look a bit wrong IMO, so I thought I'd try some Glue N Glaze. Much swearing later I gave up. Glued some glazing to the rear and floated in some GNG. I won't do the front until I see how it turns out, although it would be partially hidden by a door.

Left to fit now are the doors, guttering, canopy and roof. That will then be another one off the list.