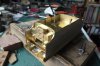

After seeing Andy Beatons delightful Midland 4-4-0 with it's full inside working motion, I felt somewhat obliged to do the same on my 2P. So an order was duly placed with Mr Griffin. Now the tender is finished I have back tracked a little to ensure the crank axle can be accomodated in the frames. Following that work, I 've now started on the

crack axle, and a rainy lunchtime has given me opportunity to drill 0.7mm through the crank webs and axles to provide a positive position for them. It took 3 drills as even the soft steel seems to take the edge of the drills pretty quickly. The next step is to clean up and check the fit of the eccentrics, before chemically blackening them, so as they wont pick up any solder when the whole lot is put in front of the blow torch to solder up.....

View attachment 15443