David Waite

Western Thunderer

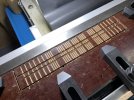

I will start with a description of the 3 All Steel Lever Frames that I built in much of my spare time over 3 years and finally finished them in 2019. They are of no particular prototype but a combination of many, a sketch was drawn up to give good proportions and sizes inc radius, tapers ect other than that they were just built through my minds eye as I went along. The smallest is a 3 Lever Frame for the control of points at WAITECOTT branch station, the next is a 15 Lever Frame, levers 1 to 14 will control the points at the loco depot and lever 15 will control the Locking on the Turntable. The largest frame is a 30 Lever Frame this will control all point work and all running signals including two Detonator placers at PINE OAK JUNCTION this frame will be fully mechanically interlocked.

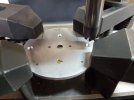

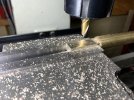

All the components were made by hand and machine or combination of both, various grades of steel including Stainless steel were used, the only non steel item used and the only item I didn’t make other than screws, nuts , springs & pins ect were the etched brass Lever number plates that I purchased from DCC Concepts. Many jigs were produced as required to hold the various pieces when being made to give a uniform build quality and positioning .

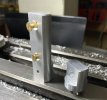

The Lever Handles are 304#SS turned & slotted and then 45%silver soldered to their Mild Steel (MS) Lever the Catch Handles are 410#SS (high tensile) and are 45%silver soldered to their MS-U bracket. The Quadrant sections are Bright MS milled, I then made a die and pressed them into shape at 4000 psi each to give them all a uniform shape including the spring back these were then Blue Zink plated “by others“ to prevent the bare metal guides that the catch block slides along from rusting.

The main shaft is 5mm dia 304#SS, each lever has a bush 45%silver soldered into a extension piece that is spot welded to the bottom of its lever there are two floating bushes between each lever on the shaft to eliminate any friction the total end play of all levers inc bushes after assembly on the 30 lever frame is .005” this gives a perfect centre position of each lever between its two adjacent quadrant sections. The Clevis pins on the catch handle are tempered pins and are 0.9 mm dia the catch rod is plain mig wire flattened and drilled at the end to suit the pins the catch block is attached to this rod by 45%silver, this rod assembly was then pickled and copper coated to prevent rusting from the flux, the spring block that is attached to the lever is only acting as a guide as the spring assembly is below the quadrant as you will see in the photos, I think I’ve covered the main sections which wouldn’t have been known unless told hopefully the photos will load, if all goes well I will add to them over the next few days.

All the components were made by hand and machine or combination of both, various grades of steel including Stainless steel were used, the only non steel item used and the only item I didn’t make other than screws, nuts , springs & pins ect were the etched brass Lever number plates that I purchased from DCC Concepts. Many jigs were produced as required to hold the various pieces when being made to give a uniform build quality and positioning .

The Lever Handles are 304#SS turned & slotted and then 45%silver soldered to their Mild Steel (MS) Lever the Catch Handles are 410#SS (high tensile) and are 45%silver soldered to their MS-U bracket. The Quadrant sections are Bright MS milled, I then made a die and pressed them into shape at 4000 psi each to give them all a uniform shape including the spring back these were then Blue Zink plated “by others“ to prevent the bare metal guides that the catch block slides along from rusting.

The main shaft is 5mm dia 304#SS, each lever has a bush 45%silver soldered into a extension piece that is spot welded to the bottom of its lever there are two floating bushes between each lever on the shaft to eliminate any friction the total end play of all levers inc bushes after assembly on the 30 lever frame is .005” this gives a perfect centre position of each lever between its two adjacent quadrant sections. The Clevis pins on the catch handle are tempered pins and are 0.9 mm dia the catch rod is plain mig wire flattened and drilled at the end to suit the pins the catch block is attached to this rod by 45%silver, this rod assembly was then pickled and copper coated to prevent rusting from the flux, the spring block that is attached to the lever is only acting as a guide as the spring assembly is below the quadrant as you will see in the photos, I think I’ve covered the main sections which wouldn’t have been known unless told hopefully the photos will load, if all goes well I will add to them over the next few days.