Dave

Western Thunderer

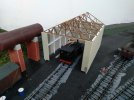

I've been trying to get the staithe/chute to work. The idea was to have the coal loads drop out of the hoppers, along the chute and into the waiting barge, as per prototype. I ought to have known that this would be nothing but trouble and that gravity doesn't scale down from previous experience with Harboro Stone.

The angle of the chute, as first made, was too shallow to get the material to flow, so it had to be steepened. It would then flow but when it came out of the end it went all over the place and not just through the hole in the baseboard. Narrowing the chute to give more control and direction worked to an extent but that was with trickling material through. When the working hopper doors open the load will all go instantly and so I replicated this by tipping in material from a wagon. The chute couldn't take so much so quickly and blocked.

I think the answer is to not have the material go into the barge at all. Instead, it will drop straight down, through a vertical chute that has a greater section than the hopper door, which should guarantee that it can take more volume than the hopper can deliver faster than the hopper can deliver it and so shouldn't block up. That's the theory, anyway. The chute into the barge will be a false one.

The other thing may be material spraying out from the hopper door and not going down the chute but instead landing on the deck. If it isn't much then I suppose this can be vacuumed off every now and again, but if it's too much then the entire thing will have to be scrapped and it's back to the drawing board to come up with something to use end-tippers. At least they will drop their loads completely clear of the rails and deck.

The angle of the chute, as first made, was too shallow to get the material to flow, so it had to be steepened. It would then flow but when it came out of the end it went all over the place and not just through the hole in the baseboard. Narrowing the chute to give more control and direction worked to an extent but that was with trickling material through. When the working hopper doors open the load will all go instantly and so I replicated this by tipping in material from a wagon. The chute couldn't take so much so quickly and blocked.

I think the answer is to not have the material go into the barge at all. Instead, it will drop straight down, through a vertical chute that has a greater section than the hopper door, which should guarantee that it can take more volume than the hopper can deliver faster than the hopper can deliver it and so shouldn't block up. That's the theory, anyway. The chute into the barge will be a false one.

The other thing may be material spraying out from the hopper door and not going down the chute but instead landing on the deck. If it isn't much then I suppose this can be vacuumed off every now and again, but if it's too much then the entire thing will have to be scrapped and it's back to the drawing board to come up with something to use end-tippers. At least they will drop their loads completely clear of the rails and deck.