Thanks for the comment, Larry. Not being a painter, I don't have any particular problem with resin boilers. It carries crisp, fine detail well and is a lot easier than trying to form taper boilers and curvaceous Stanier Belpaire fireboxes from sheet material. They do need thorough de-greasing, though.

Once painted, no-one can tell the material. It's main drawback, for me, is the lack of weight. However, the Brassmasters resins are well hollowed out and come with a nice cast tapered weight for the boiler and I have added sheet lead above the motor in the top of the firebox.

How the mighty are fallen!

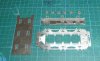

It didn't take long at all to reduce the almost complete loco previously shown to this collection of assorted bits.

I've taken it apart in order to correct the ride height and fit the pick-up mounting pads inside the frames. I had found that, although the loco was sitting dead level, it was about 0.3 to 0.4 mm too low. I'm addressing that by fitting 16 BA washers (0.3 mm thick by good luck) to the top of the coil spring locating spigots (already done) and 0.4 mm thick packers under the bogie compensating beam springs.

Copper clad pads had been prepared from thinned down sleeper strip and these have been fixed inside the frames using 5 minute epoxy. A start has been made on the wiring that connects the two sets of pads.

Whilst the frames are bare, I'll fit some material behind the large circular holes in the frames, just in front of the cab. The rear end of the firebox and ash pan block sighting right through but are not provided for in the kit.

Whilst it's all in bits, I can't decide whether to paint the chassis parts or leave it till after I've got it running.

Dave.

.

.