The small-bore tube arrived and I've now got a build order for the smokebox sorted; I'll explain in a mo.

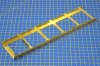

For starters, it's probably worth a couple of quick shots showing how the smokebox wrapper is formed in relation to the inner. The aim with this type of smokebox construction is not to aim for a perfectly shaped wrapper. Much like the boiler you're aiming for a smooth curve, no kinks and with the reverse bends at the bottom in the right place. The former will get the radius correct and provide the strength and structure to the finished item. Perhaps a little like this:

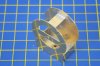

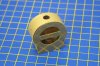

I then soldered the wrapper in place, starting by pulling it taut to the frame and tacking at the rear top and at bottom on the two sides. A quick check to make sure the handrail knob holes are in the same place on each side (I hate wonky handrails!) and solder can then be run in. After soldering the excess solder is removed, in this case with wet and dry on a flat surface. You'll note that this loco hasn't got rivets on the front face (they'd have been pressed out already), but has on the wrapper. Incidentally, if modelling 30582 with the early BR totem you'd have to remove most of those rivets as, at that time, only the rear of the smokebox had snap head rivets:

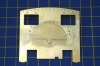

At the rear the same trick is used, ensuring the back of the smokebox is flat. The edge of the rear overlay can then be radiused and after aligning with a 7/64" drill through the locating holes it's soldered just along the bottom edge before cleaning up:

So that's the smokebox largely done. It's not perfect, but is close enough and a lot more effort has gone into this than one of my normal test builds (where the emphasis is usually on how well it works when assembled badly/quickly!). Now; that build order thing. Well I realised I could put a length of tube across the smokebox for the lubricators to plug into, providing I did it after I had permanently tightened the screw between the smokebox and boiler. So that's what I'll do, but it needs doing after I've married various parts up on the running plate and ensured the handrails are straight...

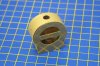

In other news I noticed a little quirk with 30582 when preparing some illustrations for the instructions over the weekend. The injector steam pipes go in a slightly different position to the rest of the class and so I realised I needed to move them otherwise I'd be irritated and regret it later. It's a bit of a hiding to nothing as you'll see when it comes to the cab interior. Much later. Much, much later. Anyway, here's how I solved the problem, which would have been much simpler to solve before any rivets were pressed out or overlays added, but I digress. First up mark where the new holes have to be. Simple to work out where, permament marker provides good contrast:

Plug the old holes with wire, soldered from the rear, crop off and rub down:

Sorted. Right, what's next?

Steph

.

.

The slivers I carve off now are so small I have to use a looking glass to even see them

The slivers I carve off now are so small I have to use a looking glass to even see them