You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Giles' misc. Work bench.

- Thread starter Giles

- Start date

Giles

Western Thunderer

Very good, but I’m still waiting for the shunting ‘orse...

Simon

..... made it into glue, mate......

JimG

Western Thunderer

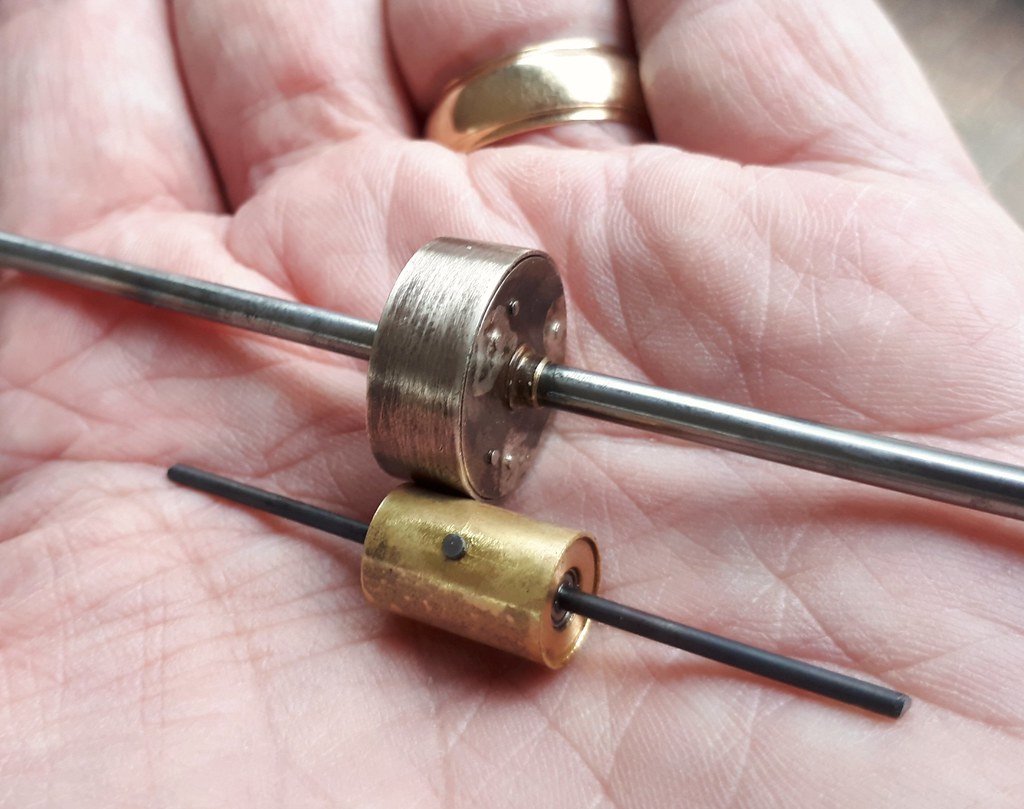

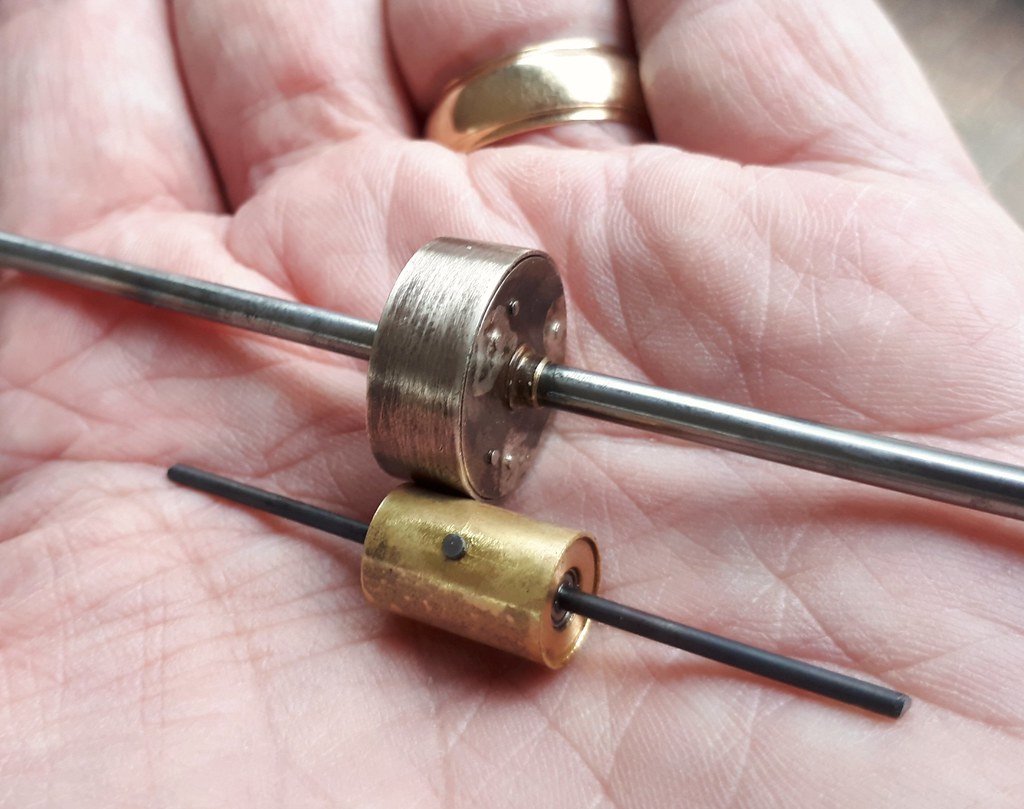

Here's your diff.... An exercise to see how practical it was. The wrong type for a traction engine, sadly - but would be just the job for a steam lorry..... it works very well (having said that, I suppose they either work or don't...). 13mm x 8.75mm diameter, with 1.5,,mm diameter output shafts. Flanged ball races on the shafts, free floating intermediate gears on a cross-shaft doing the work.

Is it a bevel gear assembly, or spur gear? I did wonder if it would have been possible to fit a spur gear differential in the housing in the rear wheel as on the full size machines.

JimG

Western Thunderer

It's a bevel gear assembly 0.3 mod gears..... one can buy 0.2 mod, and get it all a little smaller - but I don't know of a source of suitable gears for other types!

This has £20 of gears in it - a 0.2 mod version would have £40 of bits!

The spur gear differential might be less expensive since it uses ordinary spur gears, and a typical setup like shown in this video...

...might suit the traction engine situation.

Jim.

JimG

Western Thunderer

I would have to get onto a CAD screen and see what might be possible.  The large gears could be made quite thin and the cage driven by the final gear could be one-sided with stub axles for the pinions. To minimise wear on very thin, large gear wheels you might have to increase the number of pinion clusters to four or more, which could up the cost to much more than your bevel differential cost.

The large gears could be made quite thin and the cage driven by the final gear could be one-sided with stub axles for the pinions. To minimise wear on very thin, large gear wheels you might have to increase the number of pinion clusters to four or more, which could up the cost to much more than your bevel differential cost.  However, noting your success with your previous, complex projects, you might come up with an answer.

However, noting your success with your previous, complex projects, you might come up with an answer.

Jim.

The large gears could be made quite thin and the cage driven by the final gear could be one-sided with stub axles for the pinions. To minimise wear on very thin, large gear wheels you might have to increase the number of pinion clusters to four or more, which could up the cost to much more than your bevel differential cost.

The large gears could be made quite thin and the cage driven by the final gear could be one-sided with stub axles for the pinions. To minimise wear on very thin, large gear wheels you might have to increase the number of pinion clusters to four or more, which could up the cost to much more than your bevel differential cost.  However, noting your success with your previous, complex projects, you might come up with an answer.

However, noting your success with your previous, complex projects, you might come up with an answer.

Jim.

JimG

Western Thunderer

I thought about that but I wouldn't be able to get a good enough fixing on the axles with so little available width.

Maybe better with a double sided cage with thin walls to better support the pinion shafts .

I've ordered some brass gears just to give it a go.

I will await the results with interest.

Jim.

Giles

Western Thunderer

Well,

I've had a go at a spur gear differential, and it has turned out 18mm diameter x 7.5mm wide (using 0.3 Mod gears) One could reduce the main drive gear diameter to win a bit back, and perhaps squeeze 1mm (max) on the width - but that's it without dropping to MOD 0.2..

It's probably a little too thick to use in a traction engine - we may see sometime. It was certainly a great deal more work than the bevel gear type to make!

Differential 2 by giles favell, on Flickr

Differential 2 by giles favell, on Flickr

Differential 2 by giles favell, on Flickr

I've had a go at a spur gear differential, and it has turned out 18mm diameter x 7.5mm wide (using 0.3 Mod gears) One could reduce the main drive gear diameter to win a bit back, and perhaps squeeze 1mm (max) on the width - but that's it without dropping to MOD 0.2..

It's probably a little too thick to use in a traction engine - we may see sometime. It was certainly a great deal more work than the bevel gear type to make!

Differential 2 by giles favell, on Flickr

Differential 2 by giles favell, on Flickr

Differential 2 by giles favell, on Flickr

Last edited:

Giles

Western Thunderer

Here's the two side by side. Of course the out-put shafts can be any diameter within reason......

I have been reluctant to use 0.2 Mod gears, given the size of vehicles I build - but of course if you were building for smaller scales that would be fine, and you would win something of a size reduction there..... Other than that, I don't think they are going to get smaller by an order of magnitude - just a couple of mm.

The traction engine would certainly benefit from a diff, but other vehicles I've made generally manage quite well without - largly (I think) because they are not very heavy, and can slip as required.

Differentials 1 and 2 by giles favell, on Flickr

I have been reluctant to use 0.2 Mod gears, given the size of vehicles I build - but of course if you were building for smaller scales that would be fine, and you would win something of a size reduction there..... Other than that, I don't think they are going to get smaller by an order of magnitude - just a couple of mm.

The traction engine would certainly benefit from a diff, but other vehicles I've made generally manage quite well without - largly (I think) because they are not very heavy, and can slip as required.

Differentials 1 and 2 by giles favell, on Flickr

Giles

Western Thunderer

The spur gear one needs to sit just along side the wheel, with the output shaft driving it (A sprocket ring will mount around the circumference of the diff)... that's if I can find 7.5mm!

Alternatively, I can cheat and use the bevel gear diff, and run half the body of the diff in a bearing in the tender, and have a sprocket ring on the bit sticking out..... so one way or another, There's a possible solution, even if it is cheating!

Alternatively, I can cheat and use the bevel gear diff, and run half the body of the diff in a bearing in the tender, and have a sprocket ring on the bit sticking out..... so one way or another, There's a possible solution, even if it is cheating!

Giles

Western Thunderer

The latest out of the workshop. The cab and front of chassis is from the Bedford TK artic model from Ebay, and all else is scratchbuilt.

I don't need a tipper - and indeed I don't know how I shall use it - but I did want to see what the problems and solutions really were. This uses a K20 gearmotor for drive (8mm diameter), and is plenty powerful enough for the job. For the first time I needed to drive through a Cardan Shaft, which was fabricated from tube and wire, but works well. Battery is under the load-bed in the tipping body.

Eastsidepilot

Western Thunderer

The latest out of the workshop. The cab and front of chassis is from the Bedford TK artic model from Ebay, and all else is scratchbuilt.

I don't need a tipper - and indeed I don't know how I shall use it - but I did want to see what the problems and solutions really were. This uses a K20 gearmotor for drive (8mm diameter), and is plenty powerful enough for the job. For the first time I needed to drive through a Cardan Shaft, which was fabricated from tube and wire, but works well. Battery is under the load-bed in the tipping body.

How about a working wrecker to tow away your breakdowns, that's assuming you get them

.

.Col.