Lyndhurstman

Western Thunderer

Reconstruction Time Again

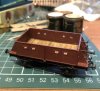

Open-ended basic boxes need support, and - whilst waiting for the order from Eileen’s (here’s hoping it hasn’t done a Midnight Runner) we have spent some time in reworking What Lies Beneath. The Stores has MJT RTR units aplenty, having bought a joblot from a concern in Ireland who couldn’t get on with them. The usual rules apply; both are rocking units, but one has been stymied bu the insertion of 20 thou plasticard packing pieces superglued in place. Gibson 3-hole discs are the circumferential conveyance choice, having their pinpoint protrusions flattened with a file, as they are surplus to requirements in this arrangement.

We have also taken the opportunity to remove the brakegear. This will be replaced with something that can be aligned with the wheels, rather than the 9” offset that would have resulted if we’d kept them. One good thing about these boxes is that the floor is nice and flat, so no major surgery of the area is needed for this work.

Cheers

Jan

Open-ended basic boxes need support, and - whilst waiting for the order from Eileen’s (here’s hoping it hasn’t done a Midnight Runner) we have spent some time in reworking What Lies Beneath. The Stores has MJT RTR units aplenty, having bought a joblot from a concern in Ireland who couldn’t get on with them. The usual rules apply; both are rocking units, but one has been stymied bu the insertion of 20 thou plasticard packing pieces superglued in place. Gibson 3-hole discs are the circumferential conveyance choice, having their pinpoint protrusions flattened with a file, as they are surplus to requirements in this arrangement.

We have also taken the opportunity to remove the brakegear. This will be replaced with something that can be aligned with the wheels, rather than the 9” offset that would have resulted if we’d kept them. One good thing about these boxes is that the floor is nice and flat, so no major surgery of the area is needed for this work.

Cheers

Jan

).

).