Lyndhurstman

Western Thunderer

Born Sloppy

Lately, every step is fraught with peril (no - I’m no talking about Beryl..)

Loathe to do ‘the usual’ and cut off the buffer housing to fit cast replacements (nice they they are) we planned to fit some nice MJT 13” heads (courtesy of MJT 2375). Unfortunately, things are not that simple....

Shanks for nothing...

The spindles of the MJT product are 3” dia. The accommodating hole is 4.2”. More slop than Beryl’s custard..

We’ve done some research* - even visiting the virtual premises of Oleo - and come up - we hope - with a solution. We’re hoping to be sent packing (brass tube), courtesy of Albion Alloys - by way of Chronos Ltd, of Dunstable.

*our research has - as you would expect - taken in a great deal of photographic representation from Mr Bartlett’s Picturesque Emporium of Wanton Wagonry. In so doing, we found this:

BR Vanwides - vacuum brake VWV VMV ZDV ZRV VEV | B783323 VEV

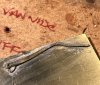

Where the buffer spindle appears thinner than the chromed neighbours in the rest of the sub-catalogue. Indeed, it looks almost identical to our rendition in its offsettedness. Is this a trick of the light, or a less than mint hydraulic unit?

Cheers

Jan

Lately, every step is fraught with peril (no - I’m no talking about Beryl..)

Loathe to do ‘the usual’ and cut off the buffer housing to fit cast replacements (nice they they are) we planned to fit some nice MJT 13” heads (courtesy of MJT 2375). Unfortunately, things are not that simple....

Shanks for nothing...

The spindles of the MJT product are 3” dia. The accommodating hole is 4.2”. More slop than Beryl’s custard..

We’ve done some research* - even visiting the virtual premises of Oleo - and come up - we hope - with a solution. We’re hoping to be sent packing (brass tube), courtesy of Albion Alloys - by way of Chronos Ltd, of Dunstable.

*our research has - as you would expect - taken in a great deal of photographic representation from Mr Bartlett’s Picturesque Emporium of Wanton Wagonry. In so doing, we found this:

BR Vanwides - vacuum brake VWV VMV ZDV ZRV VEV | B783323 VEV

Where the buffer spindle appears thinner than the chromed neighbours in the rest of the sub-catalogue. Indeed, it looks almost identical to our rendition in its offsettedness. Is this a trick of the light, or a less than mint hydraulic unit?

Cheers

Jan

). A few seconds of back and forth is all that’s needed. Any burrs (there will be some) are dealt with using a Swiss file, and the bore cleaned up with a suitable broach. Now it’s just a matter of finding a nice thin glue to hold them in the plastic housing.

). A few seconds of back and forth is all that’s needed. Any burrs (there will be some) are dealt with using a Swiss file, and the bore cleaned up with a suitable broach. Now it’s just a matter of finding a nice thin glue to hold them in the plastic housing.

I too have a soft spot for these rugged beasts; the 17x20in cylinders made them powerful bits of kit, and their short wheelbase was well suited to wobbling around the plethora of stubs peppered around East End.

I too have a soft spot for these rugged beasts; the 17x20in cylinders made them powerful bits of kit, and their short wheelbase was well suited to wobbling around the plethora of stubs peppered around East End.