mickoo

Western Thunderer

Ozzy, you could be right, though the lever on the drivers side might be for the grate, certainly there is a linkage on both sides under the cab that would match this lever in the cab, or, that lever could be for the sanding gear whos linkage also comes out of the front clothing just above the reversing rod on the drivers side.

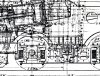

The LNER Pacifics (I've researched so far) did use a Bowden (thanks Steph, can't think why I wrote Belden as I've wired enough of the stuff over the years to know better!) cable, like you I was surprised to discover this. There's two, one to pull open the cocks and the other to close, they run to a rotary cam down under the middle cylinder whos rotary motion is converted to linear for the inside cocks and through linkages to the outside ones, I'll grab a quick photo of the relevant section on the W1 GA and a photo of the front end where the linkage goes outside that I grabbed on Mallard the other week, it is one part I want to model so took some detailed shots.

The Bowden cable cam is certainly on the firemans side (A3, A4, W1 so is not drivers side related) of the loco between the frames, and it would make sense to have the other end on the drivers side, but you would think that maybe it would be the firemans duty? or he would also have a lever as well. The W1 GA is very detailed so I'll look at that tonight, though there is no certanty that A3 and A4 follow suit at the cab end, I'll just have to wait for those GA's to be delivered....hopefully very soon

The AWS wiring was, as far as I can ascertain, always on the drivers side, certainly on A1, A3 and A4 classes and was clipped to the footplate valance and consisted mainly of 1" conduit by the look of things, certainly the junction boxes and fittings look like old conduit I used to work on.

The rod you note, I'm guessing it's the curved bit under the footplate in front of the wheel? If so that isn't a rod, it's a right angled piece of steel bolted to the bottom of the footplate to reinforce the splasher side where it joins the footplate, again a detail I need to add, but which Richard has already done on Diamond Jubilee. It is required on all three splashers and is visible from low viewing angles.

The footstep will cover the gap on the outside but not the front as it crosses the footplate toward the middle of the loco, it's only a small gap but you can see daylight through it from normal 'gods eye' viewing and it looks out of place. I'm not happy with it, so it has to be filled

Nice photo of the firebox, sadly a 107 boiler though, the demise of many a A3 in their later years as the extra weight did their frames in. It does show the extra washout plug added to 107 and 94 boilers at the front corner. The image does also show an extra hole in the clothing, several locos have these over the years (differing sizes, locations and shapes) and I'm not sure what they are for, RTCS mentions something about a hand hold but it looks the wrong shape and size for a hand hold, besides theres a great big handrail just above.

Speaking of which, the handrail knobs have massive bases and seem unique to Flying Scotsman.

and seem unique to Flying Scotsman.

The LNER Pacifics (I've researched so far) did use a Bowden (thanks Steph, can't think why I wrote Belden as I've wired enough of the stuff over the years to know better!) cable, like you I was surprised to discover this. There's two, one to pull open the cocks and the other to close, they run to a rotary cam down under the middle cylinder whos rotary motion is converted to linear for the inside cocks and through linkages to the outside ones, I'll grab a quick photo of the relevant section on the W1 GA and a photo of the front end where the linkage goes outside that I grabbed on Mallard the other week, it is one part I want to model so took some detailed shots.

The Bowden cable cam is certainly on the firemans side (A3, A4, W1 so is not drivers side related) of the loco between the frames, and it would make sense to have the other end on the drivers side, but you would think that maybe it would be the firemans duty? or he would also have a lever as well. The W1 GA is very detailed so I'll look at that tonight, though there is no certanty that A3 and A4 follow suit at the cab end, I'll just have to wait for those GA's to be delivered....hopefully very soon

The AWS wiring was, as far as I can ascertain, always on the drivers side, certainly on A1, A3 and A4 classes and was clipped to the footplate valance and consisted mainly of 1" conduit by the look of things, certainly the junction boxes and fittings look like old conduit I used to work on.

The rod you note, I'm guessing it's the curved bit under the footplate in front of the wheel? If so that isn't a rod, it's a right angled piece of steel bolted to the bottom of the footplate to reinforce the splasher side where it joins the footplate, again a detail I need to add, but which Richard has already done on Diamond Jubilee. It is required on all three splashers and is visible from low viewing angles.

The footstep will cover the gap on the outside but not the front as it crosses the footplate toward the middle of the loco, it's only a small gap but you can see daylight through it from normal 'gods eye' viewing and it looks out of place. I'm not happy with it, so it has to be filled

Nice photo of the firebox, sadly a 107 boiler though, the demise of many a A3 in their later years as the extra weight did their frames in. It does show the extra washout plug added to 107 and 94 boilers at the front corner. The image does also show an extra hole in the clothing, several locos have these over the years (differing sizes, locations and shapes) and I'm not sure what they are for, RTCS mentions something about a hand hold but it looks the wrong shape and size for a hand hold, besides theres a great big handrail just above.

Speaking of which, the handrail knobs have massive bases

and seem unique to Flying Scotsman.

and seem unique to Flying Scotsman.