Penultimate update on the Bulleid, next week I'll bore you all with something different

The roof is still several hours away from finishing (49 hours never gets any shorter

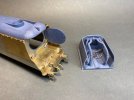

) but that will be tomorrows task, spray in primer, attach fixing studs and fit to the casing. That'll just leave the steam pipe valve handle and securing post below the buffer beam for the vac pipe glad hand.

Sand pipes get fitted during strip down as they pass behind the wheels and steam cock pipes are fitted post paint. The smokebox door locking bar with magnet needs to also go in at some point, but it's not a deal breaker before paint and the door needs the brass arms blended in with the 3D print and priming.

One thing to watch on the Bulleids is the front electric lighting conduit, there are several ways to route it so check your engine and see which way they did it, more so when the AWS battery box comes into play.

I'll do a couple of studio photos once the roof is on for closure and then it all needs a jolly good scrub and clean in the ultra sonic cleaner before heading for paint.

View attachment 212803

View attachment 212806

View attachment 212805

View attachment 212807

View attachment 212808

View attachment 212804

If someone asks for an open smoke box door then the grate and siphons will have to be a consideration, that'd also mean quite a big hacking exercise to take a lot of the lower cab and casing bulkheads out to daylight from front to rear.

If someone asks for an open smoke box door then the grate and siphons will have to be a consideration, that'd also mean quite a big hacking exercise to take a lot of the lower cab and casing bulkheads out to daylight from front to rear.