You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Mickoo's Commercial Workbench

- Thread starter mickoo

- Start date

oldravendale

Western Thunderer

That's a wonderful picture and evocative of the prototype. It was quite rare to see only one of any class on shed or in a yard - look at the number of Black 5s and 8Fs and Jinties at Willesden, WDs in the North East and Coronations at Camden. There could, of course, be visitors and if you were lucky they'd be an exception to the rule. It's one of the things which makes preserved steam a bit false as most collections will have a single example of each class. There's been a proper effort to overcome this at Loughborough where two Black Fives and two 8Fs (when they are all available together) outside the shed start to look the business, together with two standard 2 2-6-0s and an LMS version. Let's just put the green 9F on one side for a moment......

Brian

Brian

Ian Rathbone

Western Thunderer

Focalplane

Western Thunderer

All single chimneys! Quelle surprise? Non!

With a strong affinity to North American steam outlines I find the nickname Flying Pig a trifle noxious, that is until they added the dubble chimbley.

Paul, watching Black Country youtubes hence the odd sense of humor.

edit to add that Dave (below) is right about the history of chimneys. That’s the problem with buying a book and not reading it!

With a strong affinity to North American steam outlines I find the nickname Flying Pig a trifle noxious, that is until they added the dubble chimbley.

Paul, watching Black Country youtubes hence the odd sense of humor.

edit to add that Dave (below) is right about the history of chimneys. That’s the problem with buying a book and not reading it!

Last edited:

Dave Holt

Western Thunderer

Paul.

I think you've got the chimney sequence wrong. They started with enormous double chimneys and wouldn't steam. Then a single chimney, very much like a Black 5 was tried and improved things a lot. Finally, they ended up with BR Standard chimneys, which fully resolved the steaming issues.

The visual aspects are purely personal, but I much prefer the final BR type chimney.

Dave.

I think you've got the chimney sequence wrong. They started with enormous double chimneys and wouldn't steam. Then a single chimney, very much like a Black 5 was tried and improved things a lot. Finally, they ended up with BR Standard chimneys, which fully resolved the steaming issues.

The visual aspects are purely personal, but I much prefer the final BR type chimney.

Dave.

mickoo

Western Thunderer

Well, I've waited a long time for this day and finally the new 3D printer has arrived.

It's bigger than I thought, the build area is only marginally bigger than the previous hobby one, but the casing footprint is substantially bigger.

It's very shiny and also bleedin heavy.

Oddly for all it's bells and whistles, it doesn't have an on off switch, not that I've found yet.

To the right is the new curing station, much better than my previous coffee tin with UV LED strip double side taped to the interior

I really hope this is as good as they say, then I can finally get some decent prints for models, reduce wastage/time and move up the scale detail wise.

It's bigger than I thought, the build area is only marginally bigger than the previous hobby one, but the casing footprint is substantially bigger.

It's very shiny and also bleedin heavy.

Oddly for all it's bells and whistles, it doesn't have an on off switch, not that I've found yet.

To the right is the new curing station, much better than my previous coffee tin with UV LED strip double side taped to the interior

I really hope this is as good as they say, then I can finally get some decent prints for models, reduce wastage/time and move up the scale detail wise.

mickoo

Western Thunderer

Larry, that's very kind, but you give me too much credit, I am but a mere dabblerMickoo's workmanship is extraordinary.

SimonT

Western Thunderer

Mick,

You might want to look at how firm the base is that the Form is stood on. It has to be level and you will level it during initial set up. However, when it starts a print run it checks for level and this occurs after you have accepted the print run, confirmed the cassette and then the breath hole and then turned away to have a cuppa while it prints. While you are on the way to the kitchen it stops and puts an error message on the screen which you don't know about. Bah!

Looking forward to the photos.

Simon

You might want to look at how firm the base is that the Form is stood on. It has to be level and you will level it during initial set up. However, when it starts a print run it checks for level and this occurs after you have accepted the print run, confirmed the cassette and then the breath hole and then turned away to have a cuppa while it prints. While you are on the way to the kitchen it stops and puts an error message on the screen which you don't know about. Bah!

Looking forward to the photos.

Simon

mickoo

Western Thunderer

Simon,

Cheers, it's not ideal but it is firm and has been levelled. It's more a packing piece really, though that front right foot does overhang the under shelf by about 3-4 mm. I'll secure the packing piece tonight with a couple of screws as a double measure, I left a gap so the power and ethernet cables could be passed under the machine.

Cheers, it's not ideal but it is firm and has been levelled. It's more a packing piece really, though that front right foot does overhang the under shelf by about 3-4 mm. I'll secure the packing piece tonight with a couple of screws as a double measure, I left a gap so the power and ethernet cables could be passed under the machine.

michael080

Western Thunderer

While you are on the way to the kitchen it stops and puts an error message on the screen which you don't know about.

been there, done that

There is another thing to take care about. New cartriges have quite often a stuck rubber valve. It helps to squeeze the rubber before you insert the cartrige. You can see and hear a plop if it breaks open. Please do that with the cartridge upside down...

Michael

mickoo

Western Thunderer

I'm going to assume that once the tank is fitted it cannot be removed until empty, the help sheets and site are very informative....except for useless bits of information like that.

I'm also guessing that the tank is one resin type only, I can see where the resin comes in but there doesn't seem to be any way for it to go back to the tank, other than taking the tray out and pouring it back.....if I can find somewhere to pour it back into the tank, the breather is a little small.

It did make all sorts of satisfying (expensive) robot like noises when it initialized itself

I'm also guessing that the tank is one resin type only, I can see where the resin comes in but there doesn't seem to be any way for it to go back to the tank, other than taking the tray out and pouring it back.....if I can find somewhere to pour it back into the tank, the breather is a little small.

It did make all sorts of satisfying (expensive) robot like noises when it initialized itself

SimonT

Western Thunderer

I am working on the one resin, one tank basis as the Form1 worked that way. The tank holder works well should you run a second resin. When you take the tank out to clear a failed print you may find that there is a slow drip from the cartridge. I just wipe it clean. With very small objects you can join the rafts together to make a large raft that will stay on the build platform. I don't bother to clean the build paltform between runs and it doesn't contribute to failures; I've had three failures, all very small objects.

michael080

Western Thunderer

The cartridge comes in a sealed plastic bag, for good reasons. However, you can remove the cartridge once its opened and seal it with the small plastic part that is sealing the rubber valve. I do that sometimes, but not very often. I store the cartridge in its plastic bag in its carton box so that a leak cannot escape the plastic bag. After all, the resin is pretty bad stuff, you cant't remove it easily once it finds its way out of the cartridge.

You can change color if the resulting ugly mixture won't bother you. I guess you cannot change between different types of resin with the same reservoir, however. Once it's in the tank, there is no way back into the cartridge.

Michael

You can change color if the resulting ugly mixture won't bother you. I guess you cannot change between different types of resin with the same reservoir, however. Once it's in the tank, there is no way back into the cartridge.

Michael

mickoo

Western Thunderer

Okay, three prints in the bag, mixed results/feelings really

There's no shadow of doubt that the detail quality is leaps and bounds over the hobby printer, even at 50 microns.

However I'm struggling with surface quality at the moment, some of that is down to the way the machine works, some of it down the choice of resin, there are smoother ones but trade off in detail I suspect, some of it is down to me not having a clue and the rest is down to my being cavalier in the first few test runs.

I get the reason behind the printers lack of tweakability, it's a pro printer, you upload and it just does it, but there are some parts I'd like to mess with in the settings and such like.

Much like the hobby printer, orientation is everything, as are supports, the prints exhibit the same failures as the hobby printer if you do not get it right, nothing new there but I had kind of (vainly) hoped that the upload and print aspect would offset some of that error factor with clever software or whatever.

Don't get me wrong, the errors are vastly smaller than you'd get on the hobby printer but they occur, in simple terms, you still need to know what you're doing.

I picked two objects that I really want to progress as prints, they are hard objects to print and require careful though to orientation and supports, I did neither, mainly to see what the printer would do if a monkey just hit auto support, auto orientation (I will confess I did alter it a little as it was quite clear it wasn't going to work with what the software chose) kind of thing.

Both of these parts have been tweaked to work with the hobby printer, consequently when joined there are gaps, the pro printer is significantly more accurate with interference fits and tolerances.

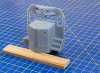

The SD35 nose section.

Essentially a four sided box, negating the front is two sides The trick here is to keep the sides parallel which requires extra supports, you can see I didn't and the lower rear section has bowed outward, this became exaggerated when it was cured and the UV light chamber is also heated. A simply solution would be a simple sacrificial transverse rod, say 3 mm in dia between the sides.

The trick here is to keep the sides parallel which requires extra supports, you can see I didn't and the lower rear section has bowed outward, this became exaggerated when it was cured and the UV light chamber is also heated. A simply solution would be a simple sacrificial transverse rod, say 3 mm in dia between the sides.

That does run the risk of that small section where the rod joins the inside remaining the correct width but the area around it bowing out, you end up with a shallow dish on the outer surface.

The vents came out well and are the correct profile when examined under magnification, the battery box lid (on the conductors side footstep) handle clip came out well too. The hand brake recess is fine but a little distorted along it's top edge, by eye it looks fine but the close up photo shows a slight bow in it.

The EMD Spartan cab front.

Another hard object to print as it will have a tendency to curl or bow. The glass rubber beading came out well and the wall thickness behind is very thin, despite the overall thickness. The test piece is an attempt to have resin sides but in the areas of glazing, be as thin as an etch, kind of....nearly...flush glazing.

The light board inspection hatches and catches came out fine and the headlight details also worked well too.

The door weather strip is too thick, a carry over from the hobby printer that always tended to under print this, therefore it had to be artificially enlarged at source to get the right result when printed.

The combined pair.

Overall not to bad for a 50 micron print, the thin edge around the nose recess for the SP light package is especially nice, a mere 0.40 mm thickness, there are a few horrido's on the surfaces in that cut out section though.

I wasn't too happy with the sand valve cover latches so I've made a slight tweak to them and now running a new print at 25 microns with more thought give the support placement.

The logical step would be to combine the cab front with the nose like I did on the CF7 test shot

Unlike the CF7 the separated nose and cab front can be used on other engines other than the SD35, a kind of parts bin of standard parts.

However it might now be advantageous to combine them and even add the cab sides and roof as one printed module, then simply make up other modules as required.

There's no shadow of doubt that the detail quality is leaps and bounds over the hobby printer, even at 50 microns.

However I'm struggling with surface quality at the moment, some of that is down to the way the machine works, some of it down the choice of resin, there are smoother ones but trade off in detail I suspect, some of it is down to me not having a clue and the rest is down to my being cavalier in the first few test runs.

I get the reason behind the printers lack of tweakability, it's a pro printer, you upload and it just does it, but there are some parts I'd like to mess with in the settings and such like.

Much like the hobby printer, orientation is everything, as are supports, the prints exhibit the same failures as the hobby printer if you do not get it right, nothing new there but I had kind of (vainly) hoped that the upload and print aspect would offset some of that error factor with clever software or whatever.

Don't get me wrong, the errors are vastly smaller than you'd get on the hobby printer but they occur, in simple terms, you still need to know what you're doing.

I picked two objects that I really want to progress as prints, they are hard objects to print and require careful though to orientation and supports, I did neither, mainly to see what the printer would do if a monkey just hit auto support, auto orientation (I will confess I did alter it a little as it was quite clear it wasn't going to work with what the software chose) kind of thing.

Both of these parts have been tweaked to work with the hobby printer, consequently when joined there are gaps, the pro printer is significantly more accurate with interference fits and tolerances.

The SD35 nose section.

Essentially a four sided box, negating the front is two sides

The trick here is to keep the sides parallel which requires extra supports, you can see I didn't and the lower rear section has bowed outward, this became exaggerated when it was cured and the UV light chamber is also heated. A simply solution would be a simple sacrificial transverse rod, say 3 mm in dia between the sides.

The trick here is to keep the sides parallel which requires extra supports, you can see I didn't and the lower rear section has bowed outward, this became exaggerated when it was cured and the UV light chamber is also heated. A simply solution would be a simple sacrificial transverse rod, say 3 mm in dia between the sides.That does run the risk of that small section where the rod joins the inside remaining the correct width but the area around it bowing out, you end up with a shallow dish on the outer surface.

The vents came out well and are the correct profile when examined under magnification, the battery box lid (on the conductors side footstep) handle clip came out well too. The hand brake recess is fine but a little distorted along it's top edge, by eye it looks fine but the close up photo shows a slight bow in it.

The EMD Spartan cab front.

Another hard object to print as it will have a tendency to curl or bow. The glass rubber beading came out well and the wall thickness behind is very thin, despite the overall thickness. The test piece is an attempt to have resin sides but in the areas of glazing, be as thin as an etch, kind of....nearly...flush glazing.

The light board inspection hatches and catches came out fine and the headlight details also worked well too.

The door weather strip is too thick, a carry over from the hobby printer that always tended to under print this, therefore it had to be artificially enlarged at source to get the right result when printed.

The combined pair.

Overall not to bad for a 50 micron print, the thin edge around the nose recess for the SP light package is especially nice, a mere 0.40 mm thickness, there are a few horrido's on the surfaces in that cut out section though.

I wasn't too happy with the sand valve cover latches so I've made a slight tweak to them and now running a new print at 25 microns with more thought give the support placement.

The logical step would be to combine the cab front with the nose like I did on the CF7 test shot

Unlike the CF7 the separated nose and cab front can be used on other engines other than the SD35, a kind of parts bin of standard parts.

However it might now be advantageous to combine them and even add the cab sides and roof as one printed module, then simply make up other modules as required.

mickoo

Western Thunderer

Left and right, the steam feed pipes run up the outside of the frames, the RH then crosses the frames in front of the fire box and runs to the rear to meet with the LH one, where they then both run into the cab.

There in lies the problem the cab comes away from the chassis for access to the motor and interior and its impossible to make the run as one and neat. Most of the pipe run will be fitted to the chassis but that last section is still being investigated.

The same applies to the steam cock pull rod whose rear end goes into the cab from a fixed chassis point and whose front end passes through the removable motion bracket, as do several other pipes.

Theres also a pipe missing from the steam heat run on the RH side, it's the upper pipe alongside the fire iron tunnel, it goes around the sandbox into the middle of the frames, I need a better understanding of that front end run as to where it goes so I can fit and trim accordingly.

There in lies the problem the cab comes away from the chassis for access to the motor and interior and its impossible to make the run as one and neat. Most of the pipe run will be fitted to the chassis but that last section is still being investigated.

The same applies to the steam cock pull rod whose rear end goes into the cab from a fixed chassis point and whose front end passes through the removable motion bracket, as do several other pipes.

Theres also a pipe missing from the steam heat run on the RH side, it's the upper pipe alongside the fire iron tunnel, it goes around the sandbox into the middle of the frames, I need a better understanding of that front end run as to where it goes so I can fit and trim accordingly.

Scale7JB

Western Thunderer

Left and right, the steam feed pipes run up the outside of the frames, the RH then crosses the frames in front of the fire box and runs to the rear to meet with the LH one, where they then both run into the cab.

There in lies the problem the cab comes away from the chassis for access to the motor and interior and its impossible to make the run as one and neat. Most of the pipe run will be fitted to the chassis but that last section is still being investigated.

The same applies to the steam cock pull rod whose rear end goes into the cab from a fixed chassis point and whose front end passes through the removable motion bracket, as do several other pipes.

Theres also a pipe missing from the steam heat run on the RH side, it's the upper pipe alongside the fire iron tunnel, it goes around the sandbox into the middle of the frames, I need a better understanding of that front end run as to where it goes so I can fit and trim accordingly.

Just checking..

Just checking..JB.