mickoo

Western Thunderer

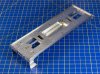

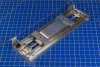

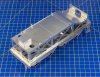

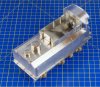

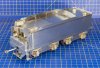

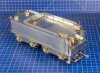

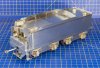

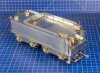

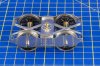

MOK King Arthur tender pretty much all done now.

There's two extra fillet plates to scratch build that go behind the drag beam next to the brake cylinder plate work and once those are in then the tender sanding pipes can be added. I've also got 95% of the information I need to add the two pipes that run down the insides of the valance.

On the RHS is the steam pipe, on the LHS is the vacuum pipe which has the drain bowl attached (nice casting supplied in the kit). Both pipes terminate next to the brake cylinder plate work and there must be some sort of bracket, the shape and position of which currently eludes me

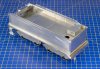

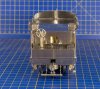

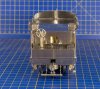

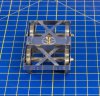

I changed the rear upper lamp iron bracket for one matching a photo I have or an early tender (the model is based in 1926 LSWR livery with SOUTHERN text) I also added little strips of etch to the footplate ones to thicken the area that simulates the pocket, as well as bending the upper tang with a dog leg in it that sits in the pocket. It's a nothing thing but does change the way the lamp irons look and makes them a little more 3D in appearance.

The biggest down side to adding the footplate lamp irons and vacuum pipe stand will be the painting of the rear LSWR panel, I may look into making the vacuum pipe stand removable, not an easy task as it relies on the tender rear bracket for a lot of it's support.

To complete I should really add the lower end of the tang sticking out of the bottom of the pocket, to that end some 5 thou strip will be cut and shaped and 'stuck' below the pockets.

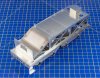

The final task will be to blend the corner castings with the sheeting, despite being soldered and smoothed I know the solder between the two will sag and create shallow depressions that will smack you in the face once high gloss paint is applied. To that end I'll fill with car knifing filler and blend smooth with 1000 grit wet n dry to give a smoother finish.

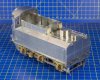

There's two extra fillet plates to scratch build that go behind the drag beam next to the brake cylinder plate work and once those are in then the tender sanding pipes can be added. I've also got 95% of the information I need to add the two pipes that run down the insides of the valance.

On the RHS is the steam pipe, on the LHS is the vacuum pipe which has the drain bowl attached (nice casting supplied in the kit). Both pipes terminate next to the brake cylinder plate work and there must be some sort of bracket, the shape and position of which currently eludes me

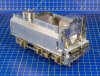

I changed the rear upper lamp iron bracket for one matching a photo I have or an early tender (the model is based in 1926 LSWR livery with SOUTHERN text) I also added little strips of etch to the footplate ones to thicken the area that simulates the pocket, as well as bending the upper tang with a dog leg in it that sits in the pocket. It's a nothing thing but does change the way the lamp irons look and makes them a little more 3D in appearance.

The biggest down side to adding the footplate lamp irons and vacuum pipe stand will be the painting of the rear LSWR panel, I may look into making the vacuum pipe stand removable, not an easy task as it relies on the tender rear bracket for a lot of it's support.

To complete I should really add the lower end of the tang sticking out of the bottom of the pocket, to that end some 5 thou strip will be cut and shaped and 'stuck' below the pockets.

The final task will be to blend the corner castings with the sheeting, despite being soldered and smoothed I know the solder between the two will sag and create shallow depressions that will smack you in the face once high gloss paint is applied. To that end I'll fill with car knifing filler and blend smooth with 1000 grit wet n dry to give a smoother finish.

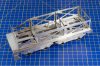

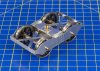

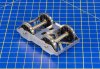

With nothing to hold the inner end it's near impossible to get the braces nice and neat.

With nothing to hold the inner end it's near impossible to get the braces nice and neat. To be fair, the areas that have proved troublesome were already mentally flagged as potential areas of concern, the test build simply confirms the design concept isn't as good as it can be.

To be fair, the areas that have proved troublesome were already mentally flagged as potential areas of concern, the test build simply confirms the design concept isn't as good as it can be.

pretty much doubling any tolerances I had.....the wrong way, pahh.

pretty much doubling any tolerances I had.....the wrong way, pahh. ' Still, they're easy to fix.

' Still, they're easy to fix.