PhilH

Western Thunderer

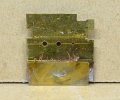

The cab roof requires 6 bolts for which I hadn't allowed half etched dimples, 4 of which were in a line at the rear of the opening hatch cover. Rather than trying to mark these 4 out on the cover I made a template to make the job easier and more accurate.

I have one of the early Unimats which has been mainly used with its vertical post as a drilling machine and this has a leadscrew with a fairly accurate metric thread. One turn of the handwheel gives 1mm and its marked with 0.05mm divisions. A piece of scrap brass sheet was bent into an 'L' shape and fixed in the vice and a scriber mounted in the 3 jaw chuck. The scriber was then used to make a series of pop marks in a line with the spacing required on the cover. A couple of extra pop marks were added before and after the required holes corresponding to the edge of the cover plus 0.45mm. The four middle holes were then drilled out to the size required for the pins representing the bolts. The two extra end holes were drilled out 0.9mm and short lengths of 0.9mm brass wire soldered in them, these serve to locate the cover correctly on each side in relation to the bolt holes.

Using the 0.9mm pins as a guide with a suitable spacer another small piece of brass was soldered to the template to give the correct distance for the line of holes from the end of the cover. Ignore the extra holes and score marks, I did say it was a piece of scrap brass !

It was then a simple matter to just clamp the cover in the template and drill the four 0.45mm dia. holes, useful if you have more than one to do.

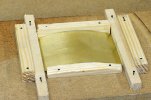

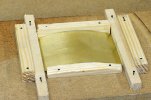

To fit the cover in the correct position in the centre of the roof I first framed round the edges of the roof with stripwood.

3 pieces of Bakalite were then trimmed in the milling machine to give parallel sides, the first was fitted at the rear to space the cover the correct distance from the back of the roof. The other two were trimmed together so they were exactly the same width and gradually reduced until they fitted between the sides of the frame and the sides of the cover, which then placed the cover exactly in the centre of the roof.

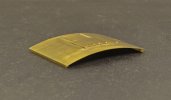

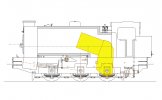

......and in place on the cab, which is now complete on the outside - just got to worry about the inside details now. With regard to the use of pins in holes for bolts and rivets, there are 109 on the finished cab unit !

tbc

I have one of the early Unimats which has been mainly used with its vertical post as a drilling machine and this has a leadscrew with a fairly accurate metric thread. One turn of the handwheel gives 1mm and its marked with 0.05mm divisions. A piece of scrap brass sheet was bent into an 'L' shape and fixed in the vice and a scriber mounted in the 3 jaw chuck. The scriber was then used to make a series of pop marks in a line with the spacing required on the cover. A couple of extra pop marks were added before and after the required holes corresponding to the edge of the cover plus 0.45mm. The four middle holes were then drilled out to the size required for the pins representing the bolts. The two extra end holes were drilled out 0.9mm and short lengths of 0.9mm brass wire soldered in them, these serve to locate the cover correctly on each side in relation to the bolt holes.

Using the 0.9mm pins as a guide with a suitable spacer another small piece of brass was soldered to the template to give the correct distance for the line of holes from the end of the cover. Ignore the extra holes and score marks, I did say it was a piece of scrap brass !

It was then a simple matter to just clamp the cover in the template and drill the four 0.45mm dia. holes, useful if you have more than one to do.

To fit the cover in the correct position in the centre of the roof I first framed round the edges of the roof with stripwood.

3 pieces of Bakalite were then trimmed in the milling machine to give parallel sides, the first was fitted at the rear to space the cover the correct distance from the back of the roof. The other two were trimmed together so they were exactly the same width and gradually reduced until they fitted between the sides of the frame and the sides of the cover, which then placed the cover exactly in the centre of the roof.

......and in place on the cab, which is now complete on the outside - just got to worry about the inside details now. With regard to the use of pins in holes for bolts and rivets, there are 109 on the finished cab unit !

tbc