You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

On Heather's Workbench - resurrection

- Thread starter Heather Kay

- Start date

Pannier Tank

Western Thunderer

41222 was one of my favourite Bletchley Loco's. I travelled on the Newport Nobby on the last day! Look forward to seeing this one develop.The loco BB was modelling was a specific member of the class, number 41222. It was a Bletchley loco in the late 1950s, and was found regularly on the Newport Pagnell branch: indeed, it was the loco that pulled the last passenger train on the branch in 1964.

Heather Kay

Western Thunderer

I don't plan on starting the LNWR coach build for a couple of weeks. I'm going away for a short break to the West Country next weekend, so this coming week I shall do some fettling on 41222.

I took it out of the box and reviewed the situation last night. I've cleaned of a lot of the remaining paint, found a few more bits where the solder has given up the ghost, and considered how to fit the washout plugs. This afternoon, I think, will see the RSU come into play.

Watch this space!

I took it out of the box and reviewed the situation last night. I've cleaned of a lot of the remaining paint, found a few more bits where the solder has given up the ghost, and considered how to fit the washout plugs. This afternoon, I think, will see the RSU come into play.

Watch this space!

Heather Kay

Western Thunderer

Things were going so well, too.

It seems Best Beloved has decided he doesn't want me to complete this model to the agreed specification after all. So, back in its box it goes. I have a feeling it may well never see the light of day again.

Actually, that's probably not true, but I learned a long time ago not to bother trying to reason with the other half when he gets into one of these moods.

It seems Best Beloved has decided he doesn't want me to complete this model to the agreed specification after all. So, back in its box it goes. I have a feeling it may well never see the light of day again.

Actually, that's probably not true, but I learned a long time ago not to bother trying to reason with the other half when he gets into one of these moods.

Dog Star

Western Thunderer

Heather,It seems Best Beloved has decided he doesn't want me to complete this model to the agreed specification after all. ... I learned a long time ago not to bother trying to reason with the other half when he gets into one of these moods.

I do hope your "BB" does not get to hear about this post... we might miss future contributions from you

.

.regards, Graham

Heather Kay

Western Thunderer

I do hope your "BB" does not get to hear about this post... we might miss future contributions from you.

I don't think it'll come to that. Next week, he'll have changed his mind again. He's already been muttering about wanting it finished in some form or other since our little "falling out".

Anyway, I've been prompted to look into the other shelf queen that's been lurking in my peripheral vision for some time - the Fowler 2F Dock Tank.

I've been acquiring bits and bobs for it for some years. The chassis is mostly there, the footplate, tanks, bunker and cab front are more or less done. I got stuck on the boiler, because the etched and rolled one in the kit was so wrong as to make you cry. Essentially, the kit maker had opted to supply Midland/LMS 3F sized firebox and smokebox details, when the 2F had the smallest "standard" boiler Crewe could produce! Being unable to immediately source any 28mm diameter brass tube, the whole thing went back into the box for the duration.

Eileen's have 28mm diameter brass tube in stock. This means I can begin to think about reconstructing the boiler and smokebox to make it look something like the real thing. The only real stumbling block I can think of, after having reviewed the box contents, is a suitable smokebox door. I have a Shedmaster Deeley door casting with the locking lugs around the edge, just the right size but it's as flat as a pancake. I have a Griffin casting with the lugs and the right domed shape, but is too large a diameter. I might have to see if my metalworking skills are up to learning how to lathe a hunk of brass to the right size.

I do have a set of Griffin brass cast locking lugs, and the hinge can be fabricated fairly easily.

I do have a set of Griffin brass cast locking lugs, and the hinge can be fabricated fairly easily.Anyway, for now, 47163 has gone back in its box. I don't feel quite in right the mood for railway modelling now. I might have a look at what needs finishing on the TSR2...

Heather Kay

Western Thunderer

As predicted, there has been a thawing of mood. Perhaps work on the Ivatt can begin again in the next few weeks.

Heather Kay

Western Thunderer

A few weeks? More like 180 weeks!

Okay, so I've been a bit busy doing other stuff that tends to bring in some cash. Still, just occasionally I gazed at the box and wondered if it was worth spending a few hours on it.

I had planned on spending the month of April on the rebuilt Scot, but having had a falling out with it last week I was at a bit of a loose end until May arrives. So, I decided it might be fun to have a stab at creating a new roof for 41222. You may recall for various reasons the kit etched roof wasn't quite large enough to fit nicely. Having now got a super snazzy riveting tool, and suitable materials, what was to stop me.

Well, quite a lot, as it turned out.

If you scan back through this thread you will find a section where I had to refit a cylinder wrapper that had become detached. Taking the loco from the box revealed the other side wrapper had decided to do the same trick, so I spent a while repairing that and making good. While I was at it, one of the front vac pipes was loose, so I attempted to repair that. I could not get it to stay firm, so I thought I'd just pour some glue in it later on. As it happened, it fell off during some other repair work, so it's now been reattached firmly. Swings and roundabouts, as they say. While poking about with the cylinders, I decided the draincock operating rods which Best Beloved had concocted from scrap etch, wire and brass screws was a little flimsy. Actually, only the rods were flimsy, so they've been ungummed and will be replaced by something more manly in due course.

Because the model is a mix of metal and plastic - some ingenious repurposing was done to make various components, I have to say - making hot repairs is a bit dicey at times. I think I've made a fairly good bodge of the wrapper repair, and haven't seriously bent any of the wiggly bits yet. Some cleaning up and it'll look okay.

I had made a start on installing washout plugs. I mean I had drilled out holes in the firebox and boiler. I'd bought some new LMS washout plug castings from Laurie Griffin, but when I studied photos they looked a bit chunky. Happily, I'd found a selection of ancient brass cast plugs of smaller diameter in the Bits Box. Although a bit iffy in the casting department, they pass muster.

By this stage I had decided to treat this build as a completion to more or less the standard that Best Beloved had started. If I can improve something I will, but otherwise I will roll with what I can do to finish the loco to an acceptable standard allowing for its various faults and idiosyncrasies.

Of course, the plugs needed to be set into the boiler, as they are a little behind the cladding on the real McCoy. I scratched the brain cell for a bit, and decided that most of the holes were through double thickness brass. If I countersunk the holes to allow the castings to drop in a little further, they'd not look too bad. There was no way they could be installed from within, at any rate. Again, not super high fidelity, but I think they'll do.

As I'd had the boiler assembly on and off a few times, inevitably bits began to work loose. They needed repairing. Two steps forward, one back…

The mixed and matched materials worried me, so I decided it might be safer to carefully remove whitemetal fittings like the front lubricators, which needed their pipework reinstating in any case, so some hot stick work could be done to fit the LG motor fitting apparatus.

To aid fitting the parts, I thought a more permanent fixing of the boiler to the body would be sensible. Someone had drilled and tapped a hole through the cab front sheet into the top of the firebox former, so I wheedled a suitable bolt in and carefully tightened it up. The slight gap at the back of the firebox magically disappeared, but a scale foot space appeared between the smokebox and the saddle. Something was out of alignment, and so far I haven't fathomed just what it might actually be. I suspect the cab is on the squiff, but that wouldn't be the only thing. Anyway, for now I have decided to leave the boiler loose fitted. On with the details. The main parts had been assembled by me all those years ago, so it was a case of fettling and fiddling to actually attached them. Again, it's not perfect, but that is just one of those things due to the varying natures of the component parts used on this loco. Happy that the motor gear sat about right, and having reinstalled the pipe that crosses under the smokebox, I refitted the refurbished lubricators.

Having sat back and reviewed things, while it had been a frustrating day of stops and starts, it's actually not too bad in the end. The tank tops need detailing, the cab needs more fitting out, there are some chassis details to find and fit, and the rear of the bunker needs the ladder putting back, but aside from all that and the roof, I can think about getting it painted.

Possibly.

Okay, so I've been a bit busy doing other stuff that tends to bring in some cash. Still, just occasionally I gazed at the box and wondered if it was worth spending a few hours on it.

I had planned on spending the month of April on the rebuilt Scot, but having had a falling out with it last week I was at a bit of a loose end until May arrives. So, I decided it might be fun to have a stab at creating a new roof for 41222. You may recall for various reasons the kit etched roof wasn't quite large enough to fit nicely. Having now got a super snazzy riveting tool, and suitable materials, what was to stop me.

Well, quite a lot, as it turned out.

If you scan back through this thread you will find a section where I had to refit a cylinder wrapper that had become detached. Taking the loco from the box revealed the other side wrapper had decided to do the same trick, so I spent a while repairing that and making good. While I was at it, one of the front vac pipes was loose, so I attempted to repair that. I could not get it to stay firm, so I thought I'd just pour some glue in it later on. As it happened, it fell off during some other repair work, so it's now been reattached firmly. Swings and roundabouts, as they say. While poking about with the cylinders, I decided the draincock operating rods which Best Beloved had concocted from scrap etch, wire and brass screws was a little flimsy. Actually, only the rods were flimsy, so they've been ungummed and will be replaced by something more manly in due course.

Because the model is a mix of metal and plastic - some ingenious repurposing was done to make various components, I have to say - making hot repairs is a bit dicey at times. I think I've made a fairly good bodge of the wrapper repair, and haven't seriously bent any of the wiggly bits yet. Some cleaning up and it'll look okay.

I had made a start on installing washout plugs. I mean I had drilled out holes in the firebox and boiler. I'd bought some new LMS washout plug castings from Laurie Griffin, but when I studied photos they looked a bit chunky. Happily, I'd found a selection of ancient brass cast plugs of smaller diameter in the Bits Box. Although a bit iffy in the casting department, they pass muster.

By this stage I had decided to treat this build as a completion to more or less the standard that Best Beloved had started. If I can improve something I will, but otherwise I will roll with what I can do to finish the loco to an acceptable standard allowing for its various faults and idiosyncrasies.

Of course, the plugs needed to be set into the boiler, as they are a little behind the cladding on the real McCoy. I scratched the brain cell for a bit, and decided that most of the holes were through double thickness brass. If I countersunk the holes to allow the castings to drop in a little further, they'd not look too bad. There was no way they could be installed from within, at any rate. Again, not super high fidelity, but I think they'll do.

As I'd had the boiler assembly on and off a few times, inevitably bits began to work loose. They needed repairing. Two steps forward, one back…

The mixed and matched materials worried me, so I decided it might be safer to carefully remove whitemetal fittings like the front lubricators, which needed their pipework reinstating in any case, so some hot stick work could be done to fit the LG motor fitting apparatus.

To aid fitting the parts, I thought a more permanent fixing of the boiler to the body would be sensible. Someone had drilled and tapped a hole through the cab front sheet into the top of the firebox former, so I wheedled a suitable bolt in and carefully tightened it up. The slight gap at the back of the firebox magically disappeared, but a scale foot space appeared between the smokebox and the saddle. Something was out of alignment, and so far I haven't fathomed just what it might actually be. I suspect the cab is on the squiff, but that wouldn't be the only thing. Anyway, for now I have decided to leave the boiler loose fitted. On with the details. The main parts had been assembled by me all those years ago, so it was a case of fettling and fiddling to actually attached them. Again, it's not perfect, but that is just one of those things due to the varying natures of the component parts used on this loco. Happy that the motor gear sat about right, and having reinstalled the pipe that crosses under the smokebox, I refitted the refurbished lubricators.

Having sat back and reviewed things, while it had been a frustrating day of stops and starts, it's actually not too bad in the end. The tank tops need detailing, the cab needs more fitting out, there are some chassis details to find and fit, and the rear of the bunker needs the ladder putting back, but aside from all that and the roof, I can think about getting it painted.

Possibly.

Last edited:

Heather Kay

Western Thunderer

A quick update before I pile into making the new roof.

A neat LG cast whistle has been fitted. I'm still pondering how to attach the boiler. I think it'll be epoxy resin at the smokebox and in the sides of the tank by the firebox. A job for this evening so it sets overnight. The tank top stays won't allow the boiler to come off again, so permanent fixing it is.

As is often the case, trying to use castings that may have been developed for the intended kit, I am finding they don't quite fit. The stays, for example. The real things are hinged affairs, bolted to the tank tops, and to lugs on the boiler and firebox protruding through the cladding. The firebox ones have to be chopped to fit such that they still align along the outer tank side. Careful filing of the LG castings is required. Here you see things posed on a tank, though I appear to be short of the lifting lugs. Whether the Bits Box will cough up four somethings suitable, or whether I should exercise my scratchbuilding skills, remains to be seen.

The front end is looking suitably cluttered. Best Beloved had concocted the front sandboxes from some plastic section with a brass filler cap, so I simply fettled them and glued them in place. I realise I have got the motor fitting bottom chambers a little too far forward. They ain't comin' off again, so skew whiff they will stay.

Note how the rivets have been accidentally punched through on the tank sides? I'm still considering how best to fill them so they don't give the appearance of a cheese grater.

Last night I broached the possibility of getting Warren H to paint the blighter. While I'm up for some lining on personal models, and it was always intended that I should, I think that in spite of the model's slightly iffy appearance it will be worth having the job done properly.

Scratchbuilding a roof this afternoon, then.

A neat LG cast whistle has been fitted. I'm still pondering how to attach the boiler. I think it'll be epoxy resin at the smokebox and in the sides of the tank by the firebox. A job for this evening so it sets overnight. The tank top stays won't allow the boiler to come off again, so permanent fixing it is.

As is often the case, trying to use castings that may have been developed for the intended kit, I am finding they don't quite fit. The stays, for example. The real things are hinged affairs, bolted to the tank tops, and to lugs on the boiler and firebox protruding through the cladding. The firebox ones have to be chopped to fit such that they still align along the outer tank side. Careful filing of the LG castings is required. Here you see things posed on a tank, though I appear to be short of the lifting lugs. Whether the Bits Box will cough up four somethings suitable, or whether I should exercise my scratchbuilding skills, remains to be seen.

The front end is looking suitably cluttered. Best Beloved had concocted the front sandboxes from some plastic section with a brass filler cap, so I simply fettled them and glued them in place. I realise I have got the motor fitting bottom chambers a little too far forward. They ain't comin' off again, so skew whiff they will stay.

Note how the rivets have been accidentally punched through on the tank sides? I'm still considering how best to fill them so they don't give the appearance of a cheese grater.

Last night I broached the possibility of getting Warren H to paint the blighter. While I'm up for some lining on personal models, and it was always intended that I should, I think that in spite of the model's slightly iffy appearance it will be worth having the job done properly.

Scratchbuilding a roof this afternoon, then.

Heather Kay

Western Thunderer

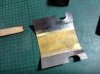

The plan was to create a new roof panel from nickel silver sheet, based on the existing one but adjusted to actually fit properly. Running rulers and whatnot across the cab and the kit roof showed that is was just right lengthwise, but oddly came up short across.

So, I did some CAD (cardboard aided design) to see if I could get the exact size needed to fit the cab. Mr Ivatt had made the decision that his Class 2 roofs wouldn't have any overhang anywhere, no doubt to the annoyance of modellers ever since.

I transferred my template to the NS sheet, and trimmed it roughly to size. I wanted then to replicate the rows of rivets all round, so did a quick bit of bad maths and came up with a distance between each rivet. I set the piece up in my GW riveter, and counted revolutions on the dial to get nice neat spacing. Or so I thought. Something, obviously since it's me, went awry. I decided to chalk it up to experience and think over.

Fiddling about with the kit roof again, I realised the real thing had a double row of rivets along the cab sides. What if I riveted a strip and sweated it inside the existing roof?

Hmm, not bad. I think this might work. Because I've added thickness to the sides, I need to add similar thickness to the central areas as well. Then it's figuring out how to fix the roof in place without glue.

This old shelf queen might actually be finished one day!

So, I did some CAD (cardboard aided design) to see if I could get the exact size needed to fit the cab. Mr Ivatt had made the decision that his Class 2 roofs wouldn't have any overhang anywhere, no doubt to the annoyance of modellers ever since.

I transferred my template to the NS sheet, and trimmed it roughly to size. I wanted then to replicate the rows of rivets all round, so did a quick bit of bad maths and came up with a distance between each rivet. I set the piece up in my GW riveter, and counted revolutions on the dial to get nice neat spacing. Or so I thought. Something, obviously since it's me, went awry. I decided to chalk it up to experience and think over.

Fiddling about with the kit roof again, I realised the real thing had a double row of rivets along the cab sides. What if I riveted a strip and sweated it inside the existing roof?

Hmm, not bad. I think this might work. Because I've added thickness to the sides, I need to add similar thickness to the central areas as well. Then it's figuring out how to fix the roof in place without glue.

This old shelf queen might actually be finished one day!

Osgood

Western Thunderer

…...So, I did some CAD (cardboard aided design) to see if I could get the exact size needed to fit the cab. …..

Yorkshire Dave

Western Thunderer

I need to add similar thickness to the central areas as well. Then it's figuring out how to fix the roof in place without glue.

Solder two tin strips of similar thickness to the nickel silver to the cab roof and fix some strip magnet to some brass L angle discreetly soldered to the 'flat apex' of the inner cab front and rear

Heather Kay

Western Thunderer

I think that's been a good day. Much progress made, which is always a good thing on any build.

With the wind in my sails, I pressed on with the roof fitting. It'll never be perfect, mainly due to a generally out-of-true cab, but I've got it about as far as I can. Rather than magnets, I've used wire. Short lengths of 0.5mm wire have been made into clips for the back edge, which just slot under the strip that Best Beloved soldered across the top of the back sheet. For the front, I've drilled holes in the strip across the front, and made short 0.8mm pegs to go into them. To hide daylight along the top of the cab sides, short lengths of brass angle have been fixed along the bottom edges of the roof.

From above, you can see the cab back is at a somewhat jaunty angle. Aside from returning this whole area to a kit of parts - which isn't going to happen, I'm afraid - this twist will have to be accepted as it is. The whole cab rear and bunker is out of true, which also becomes apparent when viewed from below: the rear buffer beam looks crooked. As I say, it's just going to have to lived with now.

I may add some further details around the roof ventilator. There are some etched rivet strips that might to the job.

With the cab roof on, and the boiler securely epoxied in place, I could fit the tank top details. You know one of those moments where something so blindingly obvious strikes you can only wonder why you didn't think of it before? I had one of those. I was pondering the lifting lugs. Sadly the Bits Box failed me, and although I rummaged high and low I could not locate anything that might serve, or indeed the missing parts from the kit itself. I had the brass angle stock out to sort the cab roof, and there it was: the answer to the lugs. Brass angle of suitable size, trimmed to more or less the right size, some deft work with files, drills and riveter, and four near identical lugs were concocted and fitted.

Things still to do include the front top lamp bracket, and some details round the back of the bunker including refitting the fragile ladder. Something for tomorrow. I'm going to stop proceedings now, and do something else for the rest of the day.

With the wind in my sails, I pressed on with the roof fitting. It'll never be perfect, mainly due to a generally out-of-true cab, but I've got it about as far as I can. Rather than magnets, I've used wire. Short lengths of 0.5mm wire have been made into clips for the back edge, which just slot under the strip that Best Beloved soldered across the top of the back sheet. For the front, I've drilled holes in the strip across the front, and made short 0.8mm pegs to go into them. To hide daylight along the top of the cab sides, short lengths of brass angle have been fixed along the bottom edges of the roof.

From above, you can see the cab back is at a somewhat jaunty angle. Aside from returning this whole area to a kit of parts - which isn't going to happen, I'm afraid - this twist will have to be accepted as it is. The whole cab rear and bunker is out of true, which also becomes apparent when viewed from below: the rear buffer beam looks crooked. As I say, it's just going to have to lived with now.

I may add some further details around the roof ventilator. There are some etched rivet strips that might to the job.

With the cab roof on, and the boiler securely epoxied in place, I could fit the tank top details. You know one of those moments where something so blindingly obvious strikes you can only wonder why you didn't think of it before? I had one of those. I was pondering the lifting lugs. Sadly the Bits Box failed me, and although I rummaged high and low I could not locate anything that might serve, or indeed the missing parts from the kit itself. I had the brass angle stock out to sort the cab roof, and there it was: the answer to the lugs. Brass angle of suitable size, trimmed to more or less the right size, some deft work with files, drills and riveter, and four near identical lugs were concocted and fitted.

Things still to do include the front top lamp bracket, and some details round the back of the bunker including refitting the fragile ladder. Something for tomorrow. I'm going to stop proceedings now, and do something else for the rest of the day.

Heather Kay

Western Thunderer

I thought it would be fun to fit the chassis to the body, install the buffer heads for the first time ever, and then get Best Beloved to have a look at his engine nearly completed.

Oh, hello. Fitting the body to the chassis seems to straighten up the twisted bunker - and there's this ginormous step that appears at the back of the roof. Oh, and the cab roof door slots don't match either. Bother! I shall be wearing my best thinking cap tonight to puzzle that one out.

Anyway, I thought a nice photo of the ensemble would be worth posting. It definitely has the air of one of Ivatt's little tank engines. Perhaps the extended journey this model has taken will have been worth the while.

Oh, hello. Fitting the body to the chassis seems to straighten up the twisted bunker - and there's this ginormous step that appears at the back of the roof. Oh, and the cab roof door slots don't match either. Bother! I shall be wearing my best thinking cap tonight to puzzle that one out.

Anyway, I thought a nice photo of the ensemble would be worth posting. It definitely has the air of one of Ivatt's little tank engines. Perhaps the extended journey this model has taken will have been worth the while.

Heather Kay

Western Thunderer

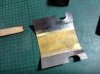

The problem: a roof too short (it's not, actually, as it scales just about right) or a cab too long (quite possible).

I let the braincell mull over the problem. The solution was obvious, really.

Cut and slide. The obvious place was through the door openings. I carefully scribed a line across the inside of the roof using engineering dividers. To aid my dodgy eyesight, I stuck some masking tape along the line. I set to with the piercing saw, trying to keep the cut as straight as possible, although it's not actually critical it should be so.

Here's the nearly finished result. I carefully tacked short bits of scrap material across the gap underneath, checking against the cab several times to make sure I wasn't accidentally getting things out of kilter. Once happy with the reinforcements, I used low temperature solder to hold a shaped length of 0.7mm wire in the slot. More solder acted as filler - yes, it is a bit of a dog's breakfast underneath - followed by filing, grinding, sanding, filling, sanding and grinding. You can still see the join, but it's actually not as bad as it looks. I think a squirt of primer on the roof will let me see where more work is required. The important thing is the roof fits and the door apertures align properly now.

I shall now turn my attention to making cab door and handrail inserts.

Heather Kay

Western Thunderer

That was Plan A, and I did try earlier this week, but made rather a horlicks of it. This is why I've gone with reworking the roof I already had.

I'm quite pleased with the way things have ended up, even though it's not anywhere near perfect. I've made a decision that this isn't a "silk purse from a sow's ear" exercise, more one of completing the model to a level that Best Beloved and I find acceptable after all these years. Being more used to kits designed in the last decade or so, it's quite eye-opening to see just how agricultural some of this stuff used to be.

I'm quite pleased with the way things have ended up, even though it's not anywhere near perfect. I've made a decision that this isn't a "silk purse from a sow's ear" exercise, more one of completing the model to a level that Best Beloved and I find acceptable after all these years. Being more used to kits designed in the last decade or so, it's quite eye-opening to see just how agricultural some of this stuff used to be.

Last edited:

warren haywood

Western Thunderer

A bit of celly filler and a few flood coats and you'll never see the join

Heather Kay

Western Thunderer

A bit of celly filler and a few flood coats and you'll never see the join

Ta. I'm preparing to contact you about painting this thing.