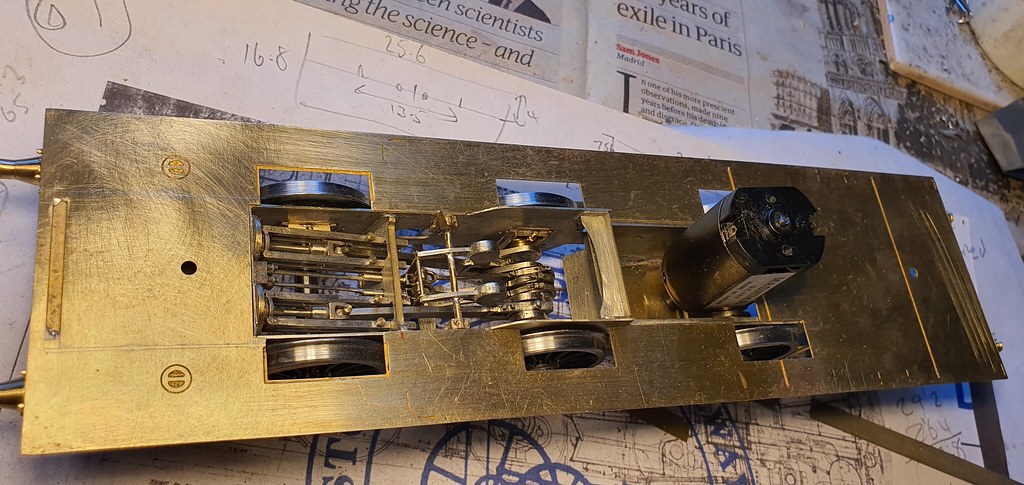

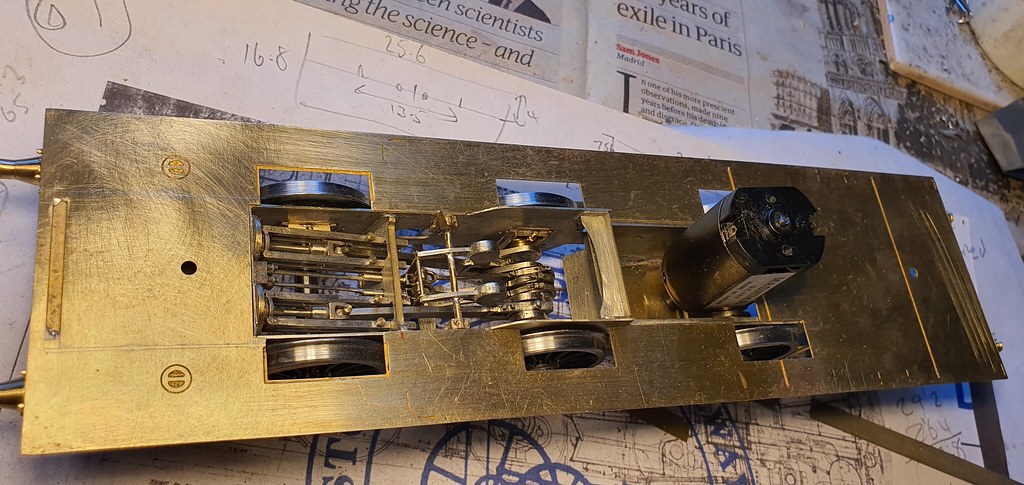

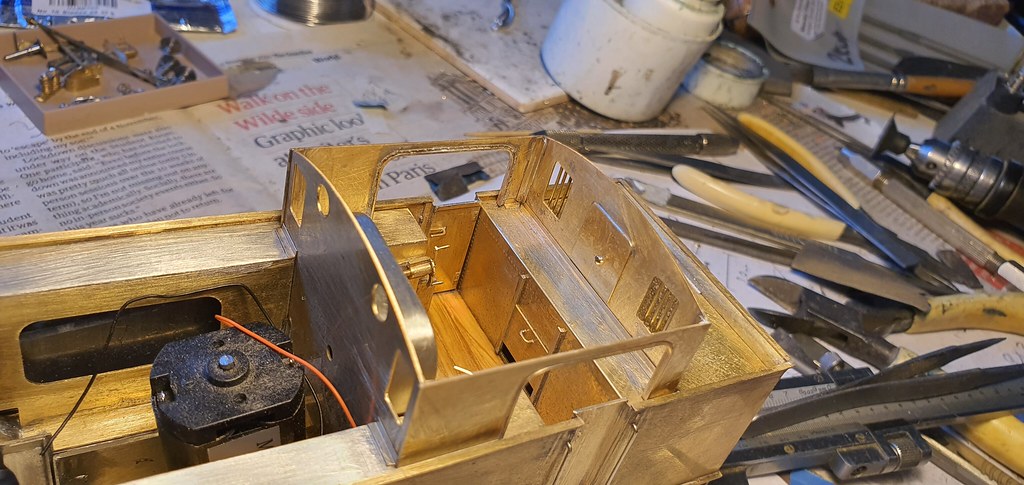

I got a little lucky with the footplate etching. Adrian drew it with a bit of extra width down each side and it sat on top of the widened chassis underneath. The footplate etch needed only a minor amount of modification to fit. The main modification was to accommodate the section of chassis above the footplate, planting it on the footplate in line with the chassis below.

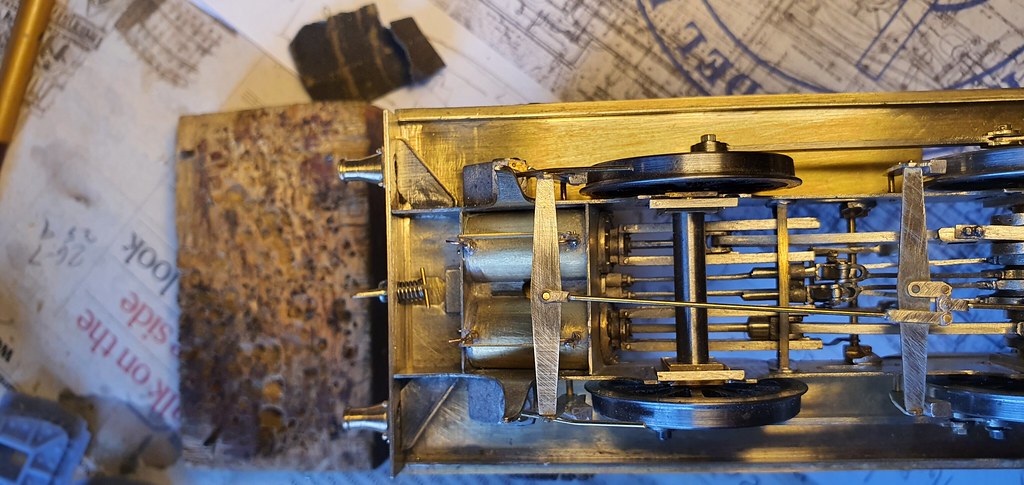

This will mean that the smokebox will have to be made slightly narrower at the base to fit between the narrowed frames, but hey, something has to be wrong here! I have spent quite a while building inside motion and detailing the frames. I hope that the new owner will be able to see all the moving parts without seeing a step in the chassis, so I'm affraid the compromise will be a narrow base to the smokebox (no-one ever notices, I've built a few like this now!)

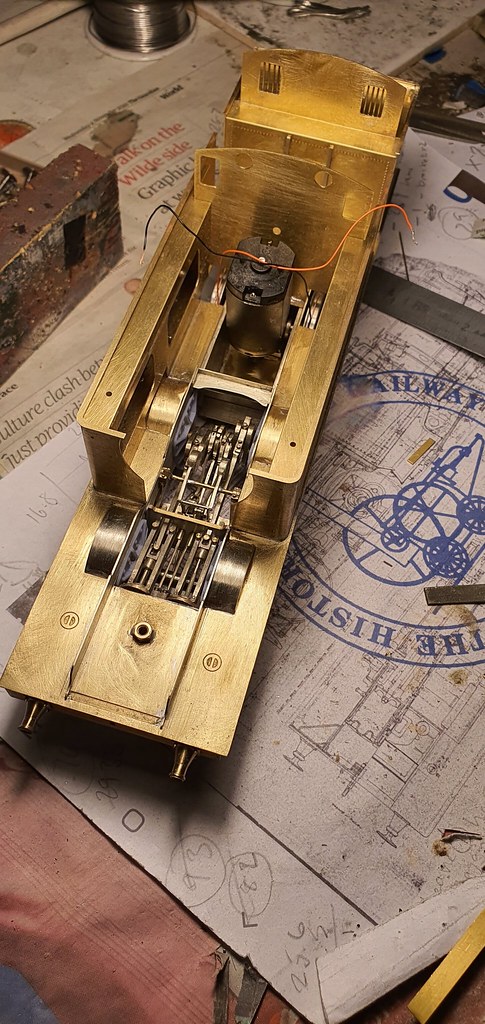

Anyway the footplate has an half etched line into which the top bit of the chassis fits. I filled this with some 0.375 mm rod and a lot of solder. The whole lot was blended in with my trusty sanding disc. I soldered the valances and buffer beams in place. The etched chassis extension is too short. It covers the bottom of the smokebox then just disappears behind the splasher. I made a new section of chassis and soldered it on top of the footplate in line with the chassis below. I used some blue roll soaked in water as a heat sink so my slot filling exploits nearby weren't disturbed.

You can see that the valances are straight-through from buffer beam to beam. Usually they swoop down to meet the bottom of the buffer beam, and this leaves the large gusset between chassis and buffer beam on view, so I decided to make some. First though I needed to make the buffers self contained. The ones supplied are nice cast tapered buffers correct for the locomotive, and they work. This means that there's a load of casting and buffer tail and a huge 10 BA nut behind the beam. I think I'd prefer my buffers not to work than have all this stuff sticking out behind the beams.....and it's in the way of the big gussets.

I took the opportunity to remove the cast fixing blobs in the corners of the fixing plate and replace them with some nice turned fake nuts from Germany.

.

.

Width-wise that is ! Hehe.

Width-wise that is ! Hehe.