Old Buffer

Western Thunderer

I second that, and it's causing a want in this quarter as well.Lovely work AdrianYour work and this kit are introducing a bit of 'want' over here

Is it as much fun to build as it looks?

Alan

I second that, and it's causing a want in this quarter as well.Lovely work AdrianYour work and this kit are introducing a bit of 'want' over here

Is it as much fun to build as it looks?

Im waiting for the 9f, hopefully Dikitriki might let me run it on Heyside...

You would need to test the chassis at an early stage as the curved 31.5 points with relatively long check rails do require some sideplay. My 9F with Alan Harris wheels won't go through them at the mo. I'm going to have to have them reprofiled.

You would need to test the chassis at an early stage as the curved 31.5 points with relatively long check rails do require some sideplay. My 9F with Alan Harris wheels won't go through them at the mo. I'm going to have to have them reprofiled.

Lovely work AdrianYour work and this kit are introducing a bit of 'want' over here

Is it as much fun to build as it looks?

ahh shucks! thanks for that you're too generous. I'm a typical Scale7 modeller plenty of projects on the go but nothing finished to show for it, unlike many other on this group.That is superb modelling, the workmanship is without question.

Alan

. I dont know much about kettles but it looks superb

. I dont know much about kettles but it looks superb

I'm a typical Scale7 modeller plenty of projects on the go but nothing finished to show for it.

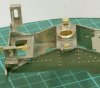

Finally in the usual tradition, with some careless ganger leaving a sleeper discarded across the track, illustrating the beam compensation!

View attachment 9497

)

)

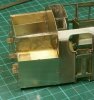

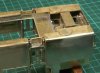

The inspiration to get back modelling has been a number of factors but Dikitriki's postings on Patriot motion has been a suitable kick up the proverbial to get the 4MT progressing.

Glad to have been of helpI look forward to your posts - partly because I have one of these to do, and it's so much easier to do when someone else has paved the way, and partly, because I like the amendments you make - viz the compensation to the bogie. I have built a number of the Sanspareil bogies which are very similar and this never occurred to me - I used wire to spring the hornblocks, but I think your way is easier.

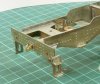

This and a few other bits of the kit are going to be expensive if I keep having to order from scale hardware!!

You're not joking. They're expensive enough to instigate a full-scale search if one hits the floor. I remember wincing at one of Rob's projects. Not because of the quality, but because of the free use of Scale Hardware components.

Some more updates to post soon about the motion but this has been long enough after such a long delay.

Motion is one of the things I look at first in a model, and perhaps the area I get most pleasure out of making. That on the 80000 is excellent and much enhances the model.

p.s. SBB more than welcome to keep this thread entertaining.

Just in case you had forgotten...I'm interested to know why you think the rear bogie has to be compensated...