I'm laser cutting a plain track base from 3mm ply so I've been experimenting with the shorter plug depth and whether to use clip or push fit. I've just been taking a bit of time reading the guides and exploring the different options - so I'm not too worried about maximising the number of chairs per print run just yet. I found the pyramid supports from Templot a little too beefy to easily cut them away without damaging the clip part so I have resorted to the finger supports generated by Lychee slicer.

I'm struggling at the minute with the rail dimensions, I'm using C&L code 125 BH but the I haven't been able to get a good set of dimensions for the custom rail settings to get it seating nicely. Do you have any recommendations for Code 125 BH I can try?

@adrian @Hayfield1

Hi Adrian,

Looking good.

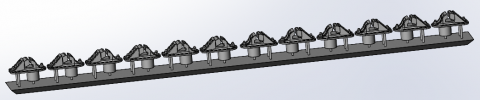

Most of the plug track experimenting to date has been done at 4mm/ft scale, and is currently working well.

I'm now tinkering about in 7mm/ft scale. In theory everything should upscale to 7mm nicely and work fine. Which it does mostly, but I can see a few areas where further tweaking might be worthwhile.

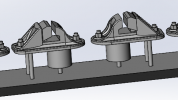

For use with the loose outer jaws option in 7mm you need a minimum plug depth of around 5mm and a minimum timber thickness of 5.5mm (or say 6mm ply) to clear the plug. With a shorter plug I don't think the loose jaws are feasible -- you would need to get the key past the rail head and locate the shorter pin in the slot both at the same time. No fun at all. The long-pin design works because the pin is already inserted in the slot before the jaw is pressed all the way down, clipping the key under the rail head in the process.

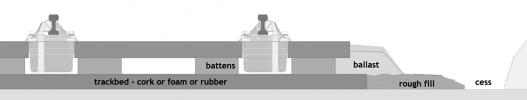

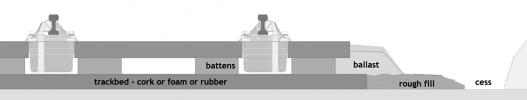

For use with 3mm timbering I suggest raising the track on 3mm battens in the old-fashioned way:

Otherwise for 3mm timbering I think you would be restricted to using the solid jaws option only (slide-on chairs).

The C&L code 125 rail represents the lightweight 85lb/yard bullhead rail sometimes found in yards and sidings, goods loops, and on lightly-used branch lines -- but not usually in pointwork. It needs the smaller S2 and L2 chairs, not currently available in Templot. If used in the standard 95lb chairs (S1, etc.) it would look a bit over-chaired. I suggest using the C&L code 131 rail which is a good representation of the common BS-95R 95lb/yd bullhead rail.

I haven't yet included pre-set dimensions for the code 125 rail because I don't have any of that to hand. I will see about getting some. If you leave the setting on the default EMGS code 75 rail, it may fit the code 125 rail ok (Templot will scale it up to 7mm/ft).

For the code 131 rail I have now added some pre-set dimensions, which will be in the next program update soon.

This is the simplified bullhead section dimensioning used in Templot:

(mm dims above are for 4mm/ft scale)

In entering your own dimensions you first need to determine the fish angle. The prototype is 1:2.75, but model rail seldom gets close to this, about 1:2 or 1:1.5 is typical of model rail. You can then set the fish centre dimensions to achieve the required head and foot depths.

These are the figures I'm using for the code 131 rail. You could enter these as custom settings if you don't want to wait for the next program update:

overall section height: 3.36 mm

head width: 1.56 mm

foot width: 1.58 mm

web thickness: 0.44 mm

fish centre from top: 1.35 mm

fish centre from bottom: 0.98 mm

fish angle: 2.0

(Make sure you have set your model scale to 7mm/ft first, because Templot stores these dimensions as full-size equivalents.)

The default pyramid supports work well in 4mm/ft scale, but I agree that they are a bit chunky when scaled up to 7mm/ft. But they do work ok and chairs can be cut from the raft with side cutters or a razor saw. If using auto-generated supports instead, check that they don't block the underside of the pin slots -- which would make it difficult to wash through the slots thoroughly. Residue resin in the slots is the main cause of the loose jaw pins not fitting. Using water-washable resin means it can be vigorously plunge washed in a bucket of water -- a bucketful of IPA is hardly practical. This is the resin I'm using:

https://www.amazon.co.uk/gp/product/B0C7BFQZ2C/

cheers,

Martin.