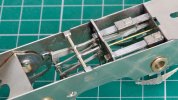

I have added the axle bushes and temporarily added the wheels and pushed the chassis to and fro along my test track.

I used the Poppy's builder box for the tender chassis and this came out flat and square, so I felt happy using the box again for the loco chassis. I had to ream out all of the holes in the side rods to fit them over the extended axles. The ends of the extended axles are thinner than the crankpin bushes so I will have to ream out all of these holes again later.

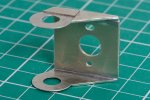

This builder box is a "special", the middle hole is elongated upwards and downwards to take the offset axle. It seems to work.

I have set up the bushes on the two outer axles to give me barely 0.2 mm side play (29 mm over faces), and the bushes on the centre axle to give me as much side play as I can have, about 1.2 mm (28 mm over faces).

I soldered the centre bushes onto the motor mount not the frames, so I can rotate the mount to find the angle where the motor will fit inside the body after I have built it.

Finally I put the wheels in for a brief trial. A Slater's axle is thicker than the extended axles (about 0.001 inch more) so I had to ream out the bushes to let me put the wheels in.

The chassis can negotiate a Setrack curve (1,020 mm radius). The chassis can also negotiate a Setrack point, but the flanges of the centre wheels tend to kiss against the insides of the rail heads - this is because the nominal 32 mm gauge narrows a bit through the curved point blade.

This ability rather exceeds expectation. I don't have a "thing" about very tight curves but this is this almost certainly the largest loco I will want to run on my layout; and so if this loco runs through a Setrack point then I can incorporate this point into my fiddle yard and dispense with having a separate test track.

Above all, the chassis runs freely and sits flat on the track and does not rock across its diagonals . . . I am very pleased with this.