RichardG

Western Thunderer

19. Underpinnings

Thank you to everyone for your continued encouragement.

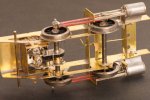

The class F is an important learning excercise for me for a few reasons, and especially because it is my first loco with suspension. At the moment, the front axle is in a frame and rocks sideways, and the rear axle is in bearings sitting loosely in the frames. This is as instructed for the kit, my only deviation has been to add some scraps of brass to stop the rear bearings rotating in the frames. One of these is visible in the photo.

I have now added some shim washers to remove the sideplay on the rear axle. Taking away about 0.6 mm of free play here is causing the motion to bind, just enough to make for a change in the sound of the motor.

The rear axle bearings are free to move most of 1.5 mm vertically and 0.5 mm front to back (there are no springs), and so I have my first floating gearbox and motor. And I am thinking, I could make my life easier if I soldered these axle bushes solid into the frames. Then the motor could be fixed to the chassis, and I would have a datum from which to tweak the rocking frame and the rest of the motion.

Please, does this sound sensible?

I think, there is so much slack around the rear bearings there is little benefit in having precision bearings here at all at the moment.

Thank you to everyone for your continued encouragement.

The class F is an important learning excercise for me for a few reasons, and especially because it is my first loco with suspension. At the moment, the front axle is in a frame and rocks sideways, and the rear axle is in bearings sitting loosely in the frames. This is as instructed for the kit, my only deviation has been to add some scraps of brass to stop the rear bearings rotating in the frames. One of these is visible in the photo.

I have now added some shim washers to remove the sideplay on the rear axle. Taking away about 0.6 mm of free play here is causing the motion to bind, just enough to make for a change in the sound of the motor.

The rear axle bearings are free to move most of 1.5 mm vertically and 0.5 mm front to back (there are no springs), and so I have my first floating gearbox and motor. And I am thinking, I could make my life easier if I soldered these axle bushes solid into the frames. Then the motor could be fixed to the chassis, and I would have a datum from which to tweak the rocking frame and the rest of the motion.

Please, does this sound sensible?

I think, there is so much slack around the rear bearings there is little benefit in having precision bearings here at all at the moment.

Last edited: