Richard Gawler

Western Thunderer

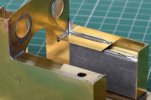

The build is transitioning from the body to the chassis . . .

This is my first mock-up to see the overall look. I expect to trim the crane jib back to somewhere near the black mark above the rear boiler band. Only the tank sides and the front of the crane base are fixed but the fit of the parts is really good. Only the pliers are providing an external support. A well-designed kit in the hands of a beginner.

I could now finish most of the superstructure by following the kit instructions, but I need to have a think about Balance and the design of the chassis before then.

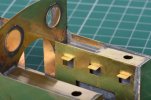

This is the build of the bodywork so far. I have put 67 g of lead into the tanks and the C of G of is now in line with the pencil.

My gut feeling is to add more lead here to try to put the weight of the body onto the four coupled wheels. The trailing axle could then be made up as a pony truck, essentially just going along for the ride and not supporting the model on the track.

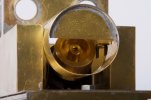

The wheels have arrived and I think the sensible thing to do now is to build the chassis as an 0-4-0 and see it run on an umbilical cord. And then play up the design of the trailing axle and the arrangement of any more ballast weights.

This is my first mock-up to see the overall look. I expect to trim the crane jib back to somewhere near the black mark above the rear boiler band. Only the tank sides and the front of the crane base are fixed but the fit of the parts is really good. Only the pliers are providing an external support. A well-designed kit in the hands of a beginner.

I could now finish most of the superstructure by following the kit instructions, but I need to have a think about Balance and the design of the chassis before then.

This is the build of the bodywork so far. I have put 67 g of lead into the tanks and the C of G of is now in line with the pencil.

My gut feeling is to add more lead here to try to put the weight of the body onto the four coupled wheels. The trailing axle could then be made up as a pony truck, essentially just going along for the ride and not supporting the model on the track.

The wheels have arrived and I think the sensible thing to do now is to build the chassis as an 0-4-0 and see it run on an umbilical cord. And then play up the design of the trailing axle and the arrangement of any more ballast weights.